QUARTER PANEL CUT AND JOIN REPLACEMENT SECTIONS (SMALL AREAS)

-

Cut the wheel arch portion.

-

Heat the quarter panel adhesive area and remove the quarter panel.

Tech Tips

Using an industrial heater gun or gas burner, heat the quarter panel to 110 to 140°C. Make sure the quarter panel does not warp.

-

Clean off any adhesive that remains on the vehicle.

Tech Tips

-

Using an industrial heater gun or gas burner, heat the adhesive to 110 to 140°C.

-

Using a scraper, scrape away the adhesive.

-

If adhesive remains, the strength of any subsequently applied adhesive will be weak.

-

-

Using a disc sander or belt sander, scuff and sand any adhesive that remains on the vehicle.

Tech Tips

Scuff at a width of approximately 10 mm (0.39 in.) over the previous adhesive coating.

-

Apply adhesive to the exposed metal areas on the vehicle. Using a spatula, spread the adhesive evenly.

-

Apply adhesive to the vehicle again.

-

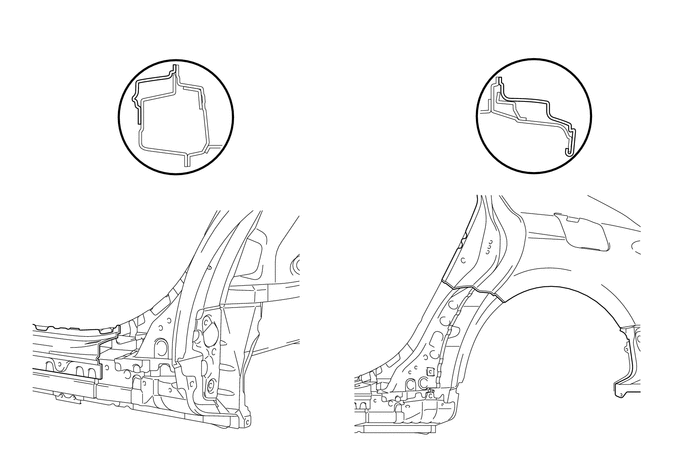

Using #60-120 grit sandpaper, scuff the adhesive application area on the new quarter panel.

-

Apply adhesive to the new quarter panel. Using a spatula, spread the adhesive evenly.

-

Using a vise grip or the palms of your hands, press the quarter panel so that the thickness of the adhesive is even.

-

Complete installation the new quarter panel.

-

Dry the adhesive areas of the new quarter panel.

Tech Tips

-

With dryer or equivalent (60°C): 60 minutes (complete hardening: 90 minutes)

-

Ambient temperature (25°C): 12 hours (complete hardening: 24 hours)

-

Quarter Panel Replacement Using Adhesive

-

REMOVAL

Symbol Meaning

Remove Weld Points

Cut and Join Location

Cut Location for Supply Parts

-

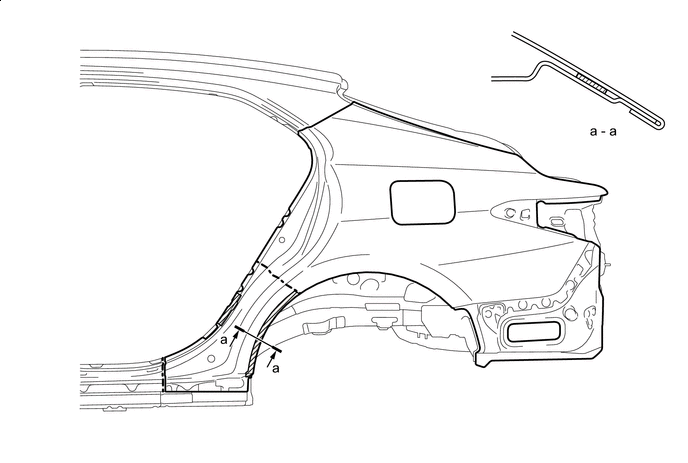

Roughly cut open the panel so that the adhesive can be reached. Cut through the adhesive with a cut chisel to remove the panel.

Tech Tips

In cases where the adhesive cannot be removed with a cut chisel, heat the adhesive with an industrial heater gun or gas burner taking care not to cause panel deformation by overheating.

Adhesive - - -

After grinding off the hemming location, remove the outer panel.

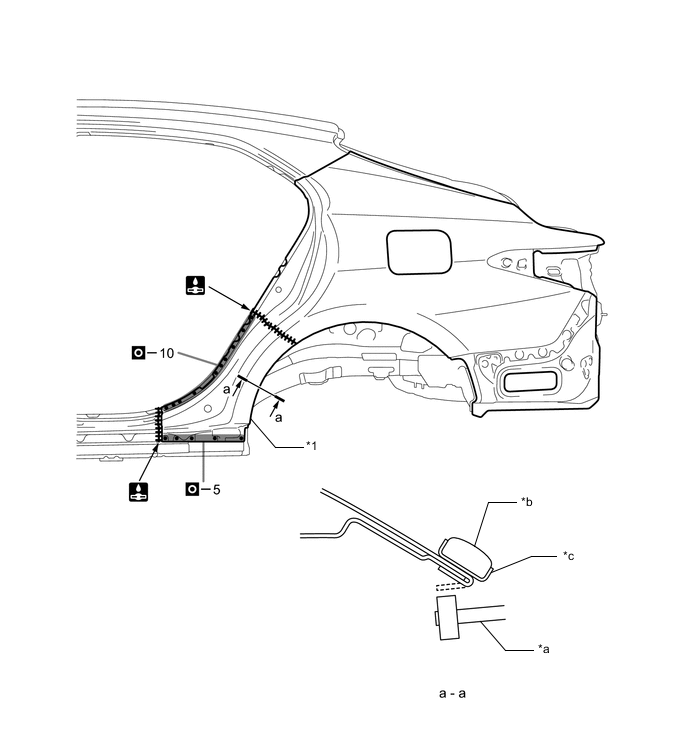

*a Disc Sander *b Hemming Location *c 110 mm (4.33 in.) - -

-

-

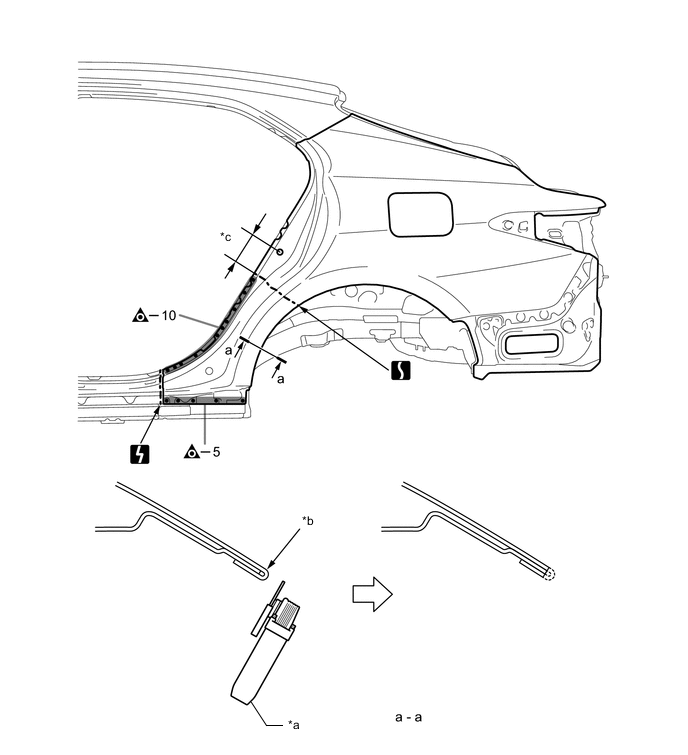

INSTALLATION

Symbol Meaning

Plug Weld

Butt Weld

-

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the finish.

-

Apply adhesive (3MTMAutomixTMPanel Bonding Adhesive #8115).

Tech Tips

-

Apply a light coat of adhesive around the plug welding points.

-

Apply enough adhesive to the panels.

Adhesive - - -

-

Bend the flange hem with a wooden hammer and dolly.

Tech Tips

Bend the panel gradually so as not to distort it.

*1 QUARTER PANEL SUB-ASSEMBLY - - *a Wooden Hammer *b Dolly *c Cloth Tape - - -

After welding, apply body sealer to the corresponding parts. (See the painting/coating)

-

After applying the top coat, apply anti-rust agent to the internal panel portion of the closed section structural weld points.

-