АВТОМАТИЧЕСКАЯ ТРАНСМИССИЯ В СБОРЕ УСТАНОВКА

-

INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

-

Inspect the torque converter clutch assembly Click here.

-

-

INSTALL TORQUE CONVERTER CLUTCH ASSEMBLY

-

Install the torque converter clutch to the automatic transmission.

-

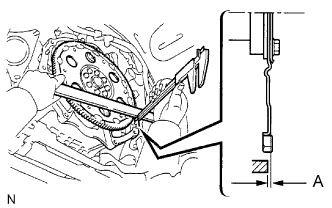

Using a vernier caliper and straightedge, measure dimension A between the transmission and the end surface of the drive plate.

Standard A = 22.28 mm (0.8772 in.) -

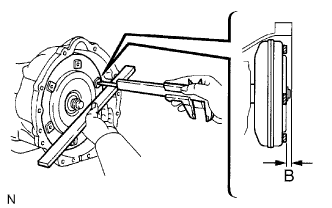

Using a vernier caliper and straightedge, measure dimension B shown in the illustration. Check that B is greater than A.

Standard B = A + 1.00 mm (0.0394 in.) or more

-

-

INSTALL TRANSFER ASSEMBLY

-

Install the transfer assembly Click here.

-

-

INSTALL NO. 1 ENGINE MOUNTING INSULATOR REAR

-

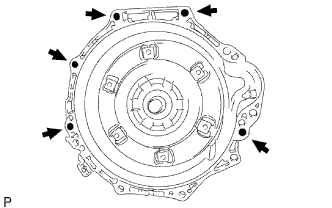

Install the engine mounting insulator to the transmission with the 4 bolts.

- Torque:

- 65 N*m { 663 kgf*cm, 48 ft.*lbf }

-

-

INSTALL AUTOMATIC TRANSMISSION ASSEMBLY

-

Install the transmission to the engine with the 5 bolts.

- Torque:

- 71 N*m { 720 kgf*cm, 53 ft.*lbf }

-

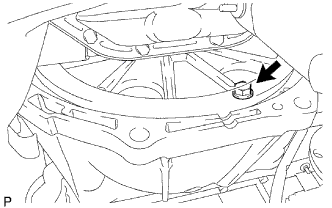

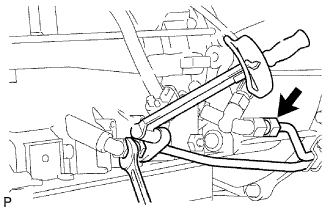

Hold the crankshaft pulley bolt with a wrench and install the 6 torque converter clutch mounting bolts.

- Torque:

- 41 N*m { 421 kgf*cm, 30 ft.*lbf }

-

-

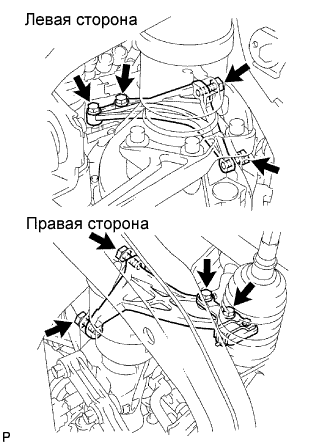

INSTALL STIFFENER PLATE

-

Install the No. 2 end plate.

-

Install the No. 4 cylinder block insulator.

-

Install the stiffener plate LH to the engine and transmission with the 4 bolts.

- Torque:

- 71 N*m { 720 kgf*cm, 53 ft.*lbf }

-

Install the stiffener plate RH (with clamp tube) to the engine and transmission with the 4 bolts.

- Torque:

- 71 N*m { 720 kgf*cm, 53 ft.*lbf }

-

-

CONNECT WIRE HARNESS

-

CONNECT CONNECTOR

-

Transmission side:

Connect the connectors.

-

Connect the temperature sensor connector.

-

Connect the park/neutral position switch connector.

-

Connect the 2 speed sensor connectors.

-

Connect the transmission wire connector.

-

-

Transfer side:

Connect the connectors.

-

Connect the indicator switch connector (4WD).

-

Connect the speedometer sensor connector.

-

Connect the indicator switch connector (L4).

-

Connect the indicator switch connector (neutral).

-

-

-

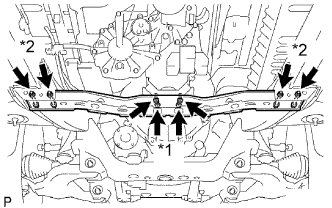

INSTALL NO. 3 FRAME CROSSMEMBER SUB-ASSEMBLY

-

*2 Install the frame crossmember with the 4 bolts and 4 nuts.

- Torque:

- 50 N*m { 510 kgf*cm, 37 ft.*lbf }

-

*1 Install the 4 set bolts of the engine mounting insulator.

- Torque:

- 27 N*m { 275 kgf*cm, 20 ft.*lbf }

-

-

INSTALL STARTER ASSEMBLY

-

Install the starter assembly Click here.

-

-

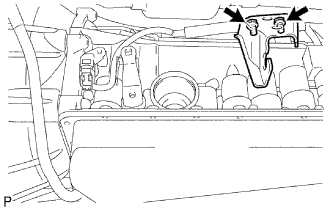

INSTALL TRANSMISSION CONTROL CABLE BRACKET

-

Install the control cable bracket with the 2 bolts.

- Torque:

- 28 N*m { 286 kgf*cm, 21 ft.*lbf }

-

-

CONNECT GROUND CABLE

-

Connect the earth wire with the nut.

- Torque:

- 5.5 N*m { 56 kgf*cm, 49 in.*lbf }

-

-

CONNECT TRANSMISSION CONTROL SHIFT CABLE ASSEMBLY

-

Connect the control cable with the clip.

-

Connect the control cable with the nut.

- Torque:

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

-

-

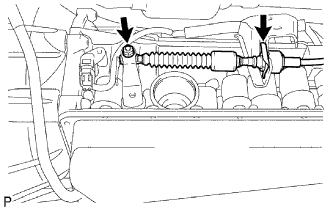

INSTALL OIL COOLER TUBE

-

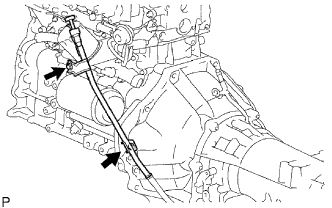

Loosely install the tip of the oil cooler tube inlet to the automatic transmission by hand.

-

Loosely install the tip of the oil cooler tube outlet to the automatic transmission by hand.

-

Install the 3 clamps with the 3 bolts.

- Torque:

- 5.0 N*m { 50 kgf*cm, 43 in.*lbf, for A and B }

- 12 N*m { 122 kgf*cm, 9 ft.*lbf, for C }

-

Using a union nut wrench, disconnect the inlet tube and outlet tube.

- Torque:

- 34 N*m { 346 kgf*cm, 25 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here

-

-

INSTALL TRANSMISSION OIL FILLER TUBE SUB-ASSEMBLY

-

Coat a new O-ring with ATF, and install it to the oil filler tube.

-

Install the oil filler tube to the transmission with the 2 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

Install the oil level gauge.

-

-

INSTALL PROPELLER SHAFT WITH CENTER BEARING ASSEMBLY

-

for TMT Made:

Install the propeller shaft with center bearing assembly Click here.

-

for TSAM Made:

Install the propeller shaft with center bearing assembly Click here.

-

-

INSTALL FRONT PROPELLER SHAFT ASSEMBLY

-

for TMT Made:

Install the front propeller shaft assembly Click here.

-

for TSAM Made:

Install the front propeller shaft assembly Click here.

-

-

INSTALL TRANSFER CASE LOWER PROTECTOR

-

Install the transfer case lower protector with the 4 bolts.

- Torque:

- 18 N*m { 183 kgf*cm, 13 ft.*lbf }

-

-

INSTALL FRONT EXHAUST PIPE ASSEMBLY

-

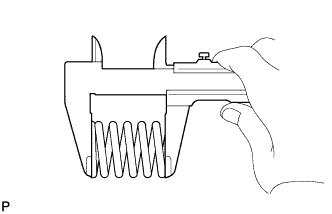

При помощи штангенциркуля замерьте длину пружины сжатия в свободном состоянии.

Минимально допустимая длина 40 мм (1,57 дюйма) Если длина в свободном состоянии меньше минимально допустимой, замените пружину сжатия.

-

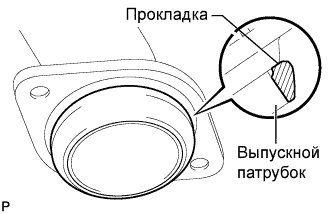

Установите переднюю трубу на опору.

-

Установите на выпускную трубу новую прокладку.

Note

-

Правильно выберите направление установки прокладки.

-

Повторное использование прокладок запрещено.

-

Чтобы обеспечить надежное уплотнение, не насаживайте прокладку на выпускную трубу с помощью передней трубы.

Tech Tips

Наденьте прокладку на выпускную трубу, равномерно обстукивая прокладку пластмассовым молотком.

-

-

Установите переднюю трубу и закрепите ее 2 пружинами сжатия и 2 болтами. Поочередно затяните гайки в несколько этапов.

- Torque:

- 43 Н*м { 438 кгс*см, 32 фунт-сила-фута }

CAUTION:

Повторное использование прокладок запрещено.

-

-

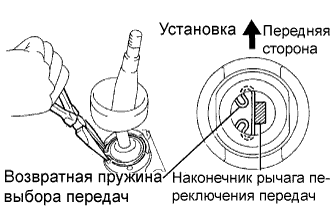

INSTALL TRANSFER HIGH AND LOW SHIFT LEVER ASSEMBLY

-

Install the transfer shift lever to the shift lever retainer.

-

Using needle-nose pliers, install the snap ring.

-

Install the shift lever boot with the 4 bolts.

- Torque:

- 18 N*m { 283 kgf*cm, 13 ft.*lbf }

Tech Tips

Apply MP grease to the tip of the transfer shift lever.

-

-

INSTALL SHIFT LEVER BOOT ASSEMBLY

-

Install the shift lever boot with the 4 screws.

-

-

ADJUST SHIFT LEVER POSITION

-

Adjust the shift lever position Click here.

-

-

ADD AUTOMATIC TRANSMISSION FLUID

-

Add automatic transmission fluid Click here.

Fluid type Toyota Genuine ATF TYPE T-IV

-

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

-

PERFORM INITIALIZATION

-

Perform initialization Click here.

Note

Certain systems need to be initialized after disconnecting and reconnecting the cable from the negative (-) battery terminal.

-

-

INSPECT SHIFT LEVER POSITION

-

Inspect the shift lever position Click here.

-

-

INSTALL CONSOLE BOX ASSEMBLY

-

Install the console box assembly Click here.

-

-

CHECK FOR EXHAUST GAS LEAKS

-

INSPECT AUTOMATIC TRANSMISSION FLUID

-

Inspect the automatic transmission fluid Click here.

-

-

INSTALL NO.3 ENGINE UNDER COVER SUB-ASSEMBLY

- Torque:

- 28 N*m { 285 kgf*cm, 21 ft.*lbf }

-

INSTALL NO. 2 ENGINE UNDER COVER

- Torque:

- 28 N*m { 285 kgf*cm, 21 ft.*lbf }

-

INSTALL NO. 1 ENGINE UNDER COVER

- Torque:

- 28 N*m { 285 kgf*cm, 21 ft.*lbf }