ECD SYSTEM, Diagnostic DTC:P0405, P0406

| DTC Code | DTC Name |

|---|---|

| P0405 | Exhaust Gas Recirculation Sensor "A" Circuit Low |

| P0406 | Exhaust Gas Recirculation Sensor "A" Circuit High |

DESCRIPTION

Refer to DTC P0401 Click here.

The EGR actuator is electrically opened or closed by the ECM. In order to ensure optimum control of the exhaust gas recirculation rate the ECM must continuously detect the exact position. The position of the EGR actuator is monitored by the EGR valve position sensor.

The DTC motor operates the EGR actuator. The position sensor is a Hall sensor. The Hall sensor detects the revolutions of the servo motor. The position of the EGR actuator is calculated.

The EGR position sensor is installed to the EGR valve assembly and is supplied with 5 V from the ECM.

A bridge circuit (H-bridge) is used to control the servo motor, which allows the servo motor to be operated in the opposite direction. The H-bridge circuit is monitored for diagnosis. An H-bridge electric circuit includes 5 switching elements, which are connected together in the form of the capital letter H.

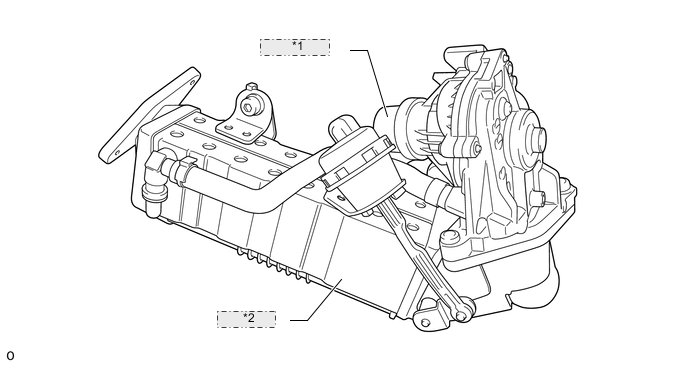

| *1 | EGR Actuator |

| *2 | EGR Cooler |

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0405 | EGR valve position sensor output voltage is 0.1 V or less for 0.22 seconds. (3 trip detection logic) |

|

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0406 | EGR valve position sensor output voltage is 4.9 V or higher for 0.22 seconds. (3 trip detection logic) |

|

| DTC No. | Data List |

|---|---|

| P0405 P0406 |

|

WIRING DIAGRAM

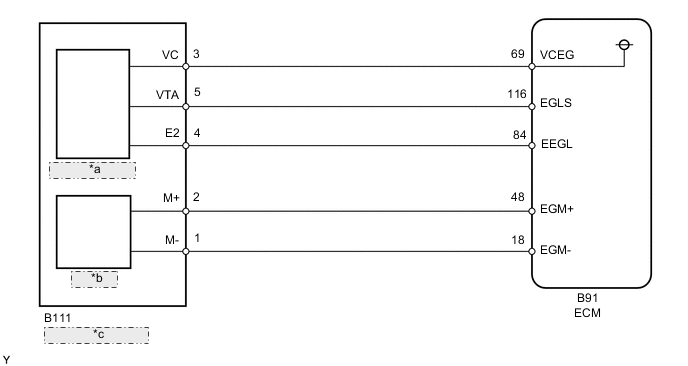

| *a | Position Sensor |

| *b | Actuator |

| *c | EGR Valve Assembly |

CAUTION / NOTICE / HINT

Note

-

When replacing the ECM, the ECM needs Registration and Initialization Click here.

-

After replacing the EGR valve assembly, the ECM needs initialization Click here.

Tech Tips

-

When the ECM must be replaced, before replacing the ECM, perform the "Learning Values Save" function using the GTS. Then after installing the new ECM, perform all of the initialization/registrations for the "Learning Values Write" function by following the instructions shown on the GTS display.

-

Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

PROCEDURE

-

PERFORM ACTIVE TEST USING GTS (ACTUATOR TEST OF FAN HIGH SPEED AND LOW SPEED)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Actuator Test of Fan High Speed and Actuator Test of Fan Low Speed.

OK Cooling fan operates according to operation.

NG

REPAIR OR REPLACE COOLING FAN SYSTEM Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (EGR VALVE ASSEMBLY - ECM)

-

Disconnect the EGR valve assembly connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition B111-3 (VC) - B91-69 (VCEG) Always Below 1 Ω B111-5 (VTA) - B91-116 (EGLS) Always Below 1 Ω B111-4 (E2) - B91-84 (EEGL) Always Below 1 Ω B111-3 (VC) or B91-69 (VCEG) - Body ground Always 10 kΩ or higher B111-5 (VTA) or B91-116 (EGLS) - Body ground Always 10 kΩ or higher B111-4 (E2) or B91-84 (EEGL) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (VC VOLTAGE)

-

Text in Illustration *a Front view of wire harness connector

(to EGR valve assembly)

Disconnect the EGR valve assembly connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition B111-3 (VC) - B111-4 (E2) Ignition switch ON 4.5 to 5.5 V

NG

REPLACE ECM Click here

OK

-

-

REPLACE EGR VALVE ASSEMBLY

-

Replace the EGR valve assembly Click here.

-

Perform EGR learning value reset Click here.

NEXT

-

-

CHECK WHETHER DTC OUTPUT RECURS (DTC P0405 or P0406)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Clear the DTCs Click here.

-

Turn the ignition switch off and wait for 60 seconds or more [A].

-

Perform road test [B].

-

Repeat [A] and [B] for the number of trips detected.

-

Enter the following menus: Powertrain / Powertrain / Engine and ECT / Trouble Codes.

-

Read the DTCs.

Result Result Proceed to No DTC output A DTC P0405 or P0406 B

A

END

B

REPLACE ECM Click here

-

-

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

Repair or replace the harness or connector.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPAIR OR REPLACE COOLING FAN SYSTEM

-

Repair or replace the cooling fan system Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPLACE ECM

-

Replace the ECM Click here.

NEXT

-

-

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Clear the DTCs Click here.

-

Turn the ignition switch off and wait for 60 seconds or more [A].

-

Perform road test [B].

-

Repeat [A] and [B] for the number of trips detected.

-

Enter the following menus: Powertrain / Powertrain / Engine and ECT / Trouble Codes.

-

Confirm that the DTC is not output again.

NEXT

END

-