STOP AND START SYSTEM(for V35A-FTS), Diagnostic DTC:P033562

| DTC Code | DTC Name |

|---|---|

| P033562 | Crankshaft Position Sensor "A" Signal Compare Failure |

DESCRIPTION

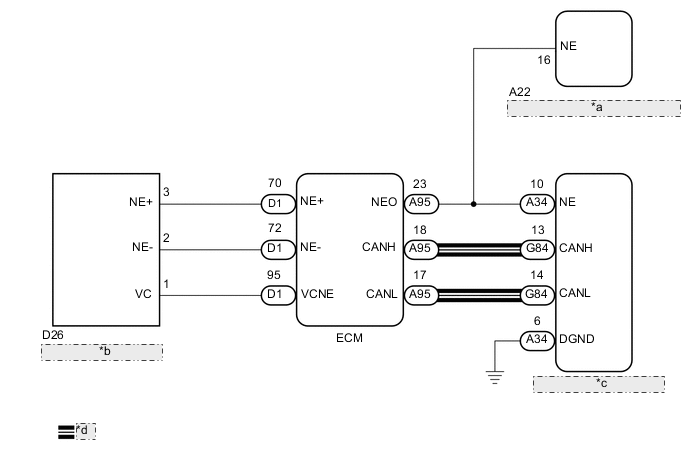

The crankshaft position sensor sends an engine speed signal (NE signal) to the ECM. The engine speed signal is then sent directly from the NEO terminal of the ECM to the engine stop and start ECU. Additionally, the ECM sends the engine speed to the engine stop and start ECU via CAN communication. The engine stop and start ECU compares the NE signal and engine speed received via CAN communication to check for errors in the NE signal.

If the NE signal is abnormal, the engine stop and start ECU will blink the stop and start cancel indicator and stores DTC P033562.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | Warning Indicate | Memory | Note |

|---|---|---|---|---|---|---|

| P033562 | Crankshaft Position Sensor "A" Signal Compare Failure | All of the following conditions are met for 10 seconds (1 trip detection logic):

|

|

Blinks | DTC stored | SAE Code: P0335 |

CONFIRMATION DRIVING PATTERN

-

CONFIRMATION AFTER TROUBLESHOOTING

Tech Tips

-

If the cable is disconnected from the battery terminal, stop and start control is prohibited until refresh charge is completed.

In this case, let the vehicle idle to complete the refresh charge. The refresh charge is complete when the Data List item Status of Battery Charge Control changes from "Refresh Charge Mode". (Usually, idling the engine for 5 to 60 minutes with the battery fluid temperature at 11°C (52°F) or higher, the refresh charge will be completed.)

-

If the GTS is not available and the Data List item Status of Battery Charge Control cannot be checked, charge the battery by idling the engine for approximately 5 to 60 minutes or driving the vehicle, and then drive the vehicle and check that stop and start control operates.

If the engine is started with the hood open, the system determines that a jump start has occurred. Therefore, make sure that the hood is closed before starting the engine and driving the vehicle.

-

After the refresh charge completes, turn the engine switch off, wait for at least 30 seconds, and then start the engine again.

If the vehicle enters refresh charge mode again while the engine is idling, the initial refresh charge did not properly complete, so wait for the refresh charge to complete.

-

Allow the engine to idle for 3 minutes after the engine warms up and check that the engine speed is within 50 rpm of the target idle speed.

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG)

-

Turn the GTS on.

-

Clear the DTCs.

Powertrain > Stop and Start > Clear DTCs -

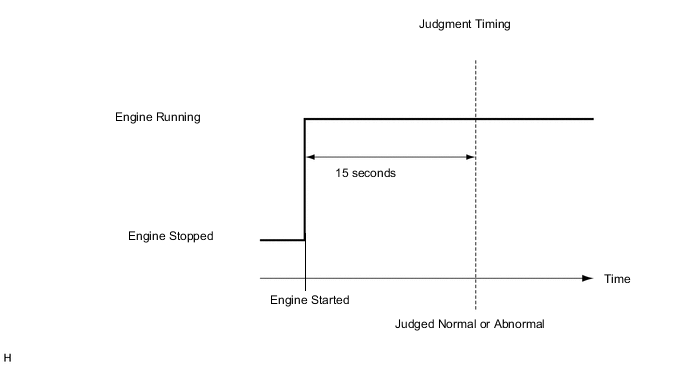

Start the engine and wait for at least 15 seconds.

-

Check that DTCs are not output.

Powertrain > Stop and Start > Trouble Codes

-

-

STOP AND START SYSTEM OPERATION CHECK

Tech Tips

-

If the cable is disconnected from the battery terminal, stop and start control is prohibited until refresh charge is completed.

In this case, let the vehicle idle to complete the refresh charge. The refresh charge is complete when the Data List item Status of Battery Charge Control changes from "Refresh Charge Mode". (Usually, idling the engine for 5 to 60 minutes with the battery fluid temperature at 11°C (52°F) or higher, the refresh charge will be completed.)

-

If the GTS is not available and the Data List item Status of Battery Charge Control cannot be checked, charge the battery by idling the engine for approximately 5 to 60 minutes or driving the vehicle, and then drive the vehicle and check that stop and start control operates.

If the engine is started with the hood open, the system determines that a jump start has occurred. Therefore, make sure that the hood is closed before starting the engine and driving the vehicle.

-

After the refresh charge completes, turn the engine switch off, wait for at least 30 seconds, and then start the engine again. If the vehicle enters refresh charge mode again while the engine is idling, the initial refresh charge did not properly complete, so wait for the refresh charge to complete.

-

Start the engine and warm it up.

-

Turn the air conditioning system off.

-

Drive the vehicle at 7 km/h (4.3 mph) or more.

CAUTION:

When performing Confirmation Driving Pattern, obey all speed limits and traffic laws.

-

Depress the brake pedal and stop the vehicle.

-

Allow the engine to stop by stop and start control. (Keep the shift lever in D.)

-

Release the brake pedal with the shift lever in D to start the engine.

-

WIRING DIAGRAM

| *a | Certification ECU (Smart Key ECU Assembly) |

| *b | Crank Position Sensor |

| *c | Engine Stop and Start ECU |

| *d | CAN Communication Line |

CAUTION / NOTICE / HINT

Note

-

Before replacing the engine stop and start ECU, read the number of starter operations and write it into a new engine stop and start ECU.

-

After replacing the engine stop and start ECU or air conditioning amplifier assembly, reset and perform learning of the air conditioning information in the engine stop and start ECU.

-

After replacing the engine stop and start ECU or airbag sensor assembly, clear and calibrate the deceleration sensor zero point in the engine stop and start ECU.

Tech Tips

-

Using the GTS, read the freeze frame data before troubleshooting. System condition information is recorded as freeze frame data the moment a DTC is stored. This information can be useful when troubleshooting.

-

DTCs for the stop and start system are not cleared even if the malfunction has been repaired. After repairing the malfunction, be sure to clear the DTCs.

PROCEDURE

-

CHECK DTC OUTPUT (SFI SYSTEM)

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine / Trouble Codes.

Powertrain > Engine > Trouble Codes -

Read the DTCs.

Result Result Proceed to SFI system DTCs are not output A SFI system crankshaft position sensor circuit DTC is output B

B

GO TO SFI SYSTEM Click here

A

-

-

READ VALUE USING GTS (ENGINE SPEED)

-

Connect the GTS to the DLC3

-

Start the engine.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Stop and Start / Data List / Engine Speed.

Powertrain > Stop and Start > Data ListTester Display Engine Speed -

According to the display on the GTS, read the Data List.

OK Engine speed signal is input (the speeds displayed on the tachometer and the GTS are almost the same). Result Proceed to OK NG

OK

USE SIMULATION METHOD TO CHECK Click here

NG

-

-

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - ECM)

-

Turn the engine switch off.

-

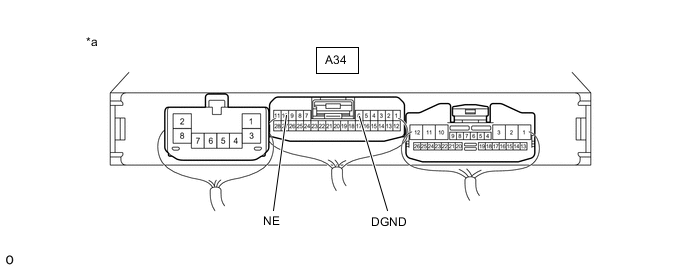

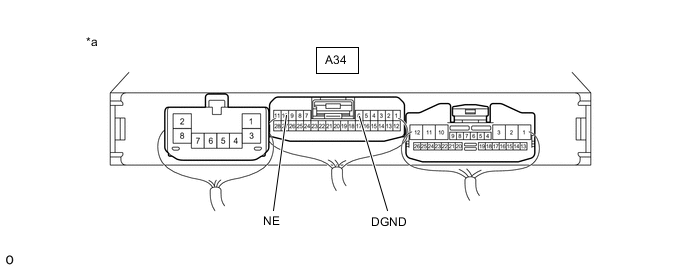

Disconnect the A34 engine stop and start ECU connector.

-

Disconnect the A95 ECM connector.

-

Disconnect the A22 certification ECU (smart key ECU assembly) connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A34-10 (NE) - A95-23 (NEO) Always Below 1 Ω A34-10 (NE) or A95-23 (NEO) - Body ground and other terminals Always 10 kΩ or higher Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HARNESS AND CONNECTOR (ENGINE STOP AND START ECU - BODY GROUND)

-

Disconnect the A34 engine stop and start ECU connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A34-6 (DGND) - Body ground Always Below 1 Ω Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK ENGINE STOP AND START ECU (NE SIGNAL INPUT)

-

Start the engine and warm it up.

-

Connect an oscilloscope to the NE and DGND terminals of the engine stop and start ECU connector.

*a Component with harness connected

(Engine Stop and Start ECU)

- - -

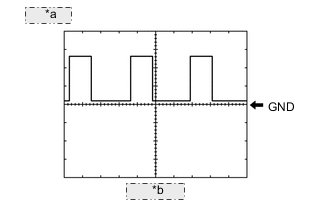

*a 5 V/DIV. *b 2 ms./DIV. Check the signal waveform according to the condition(s) in the table below.

Item Condition Tester Connection A34-10 (NE) - A34-6 (DGND) Tool Setting 5 V/DIV., 2 ms./DIV. Condition Idling after engine warmed up Result Result Proceed to Pulse generation

(See waveform)

A Stuck at 0 to 1.5 V B Stuck at 8 to 14 V C

A

REPLACE ENGINE STOP AND START ECU Click here

C

GO TO SFI SYSTEM Click here

B

-

-

CHECK ENGINE STOP AND START ECU (NE TERMINAL VOLTAGE)

*a Component with harness connected

(Engine Stop and Start ECU)

- -

-

Disconnect the A95 ECM connector.

-

Turn the engine switch on (IG).

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition A34-10 (NE) - A34-6 (DGND) Engine switch on (IG) 8 to 14 V Tech Tips

DTCs may be stored during this inspection. Check for DTCs and clear them using the GTS.

Result Proceed to OK NG

OK

GO TO SFI SYSTEM Click here

NG

REPLACE ENGINE STOP AND START ECU Click here

-