WATER PUMP INSTALLATION

-

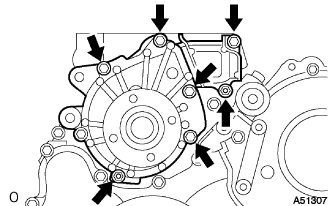

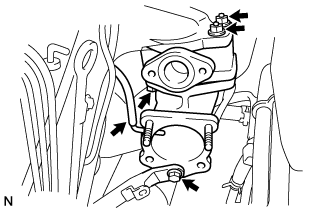

INSTALL WATER PUMP ASSEMBLY

-

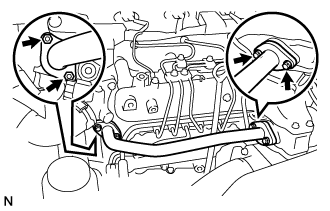

Install a new gasket and the water pump with the 5 bolts and 2 nuts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

-

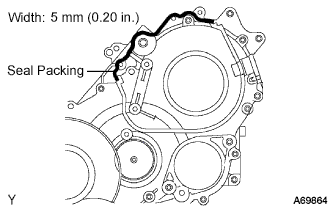

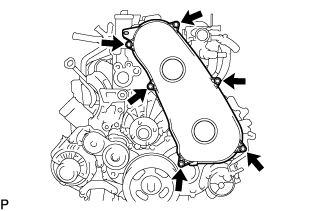

INSTALL TIMING BELT COVER NO.2

-

Remove old seal packing (FIPG) from the timing gear case.

-

Apply seal packing to the specific places shown in the illustration.

Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note

-

After applying FIPG, install the timing belt No.2 cover within 3 minutes and tighten its bolts and nuts within 15 minutes.

-

Do not start the engine 2 hours after the installation.

-

-

Fix the timing belt cover No.2 with the 4 bolts and nuts.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

-

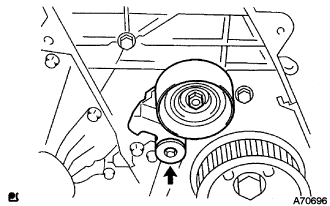

INSTALL TIMING BELT IDLER SUB-ASSEMBLY NO.1

-

Using a 10 mm socket hexagon wrench, install the new plate washer and timing belt idler No.1.

- Torque:

- 35 N*m { 357 kgf*cm, 26 ft.*lbf }

-

-

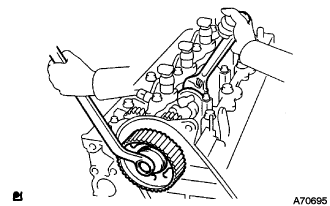

INSTALL CAMSHAFT TIMING PULLEY

-

Install the camshaft timing pulley.

-

Tighten the bolt for the camshaft timing pulley while holding the camshaft with a monkey wrench.

- Torque:

- 98 N*m { 1,000 kgf*cm, 72 ft.*lbf }

-

-

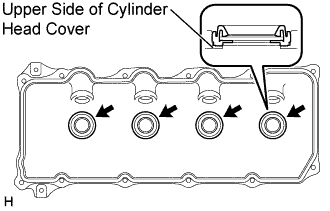

INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

-

Install 4 new No. 3 cylinder head cover gaskets to the cylinder head cover as shown in the illustration.

Note

-

Do not install the gaskets at an angle.

-

Keep the lip of the gasket free from foreign materials.

-

-

Install a new cylinder head cover gasket to the cylinder head cover.

-

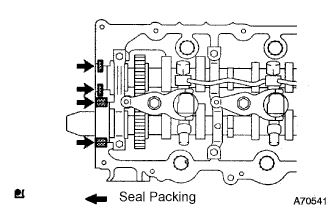

Remove old seal packing (FIPG) from the cylinder head.

-

Apply a seal packing to the specific places described in the illustration.

Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note

-

After applying the seal packing, parts must be assembled within 3 minutes, and then tighten within 15 minutes.

-

Otherwise the material must be removed and reapplied.

-

Do not start the engine 2 hour after the installation.

-

-

Install the cylinder head cover with 10 bolts and 2 nuts.

- Torque:

- 9.0 N*m { 92 kgf*cm, 80 in.*lbf }

-

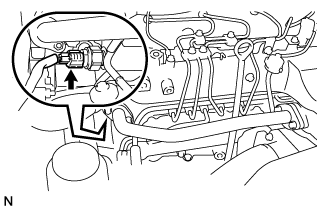

Connect the ventilation hose.

-

Install a new nozzle holder seal.

-

-

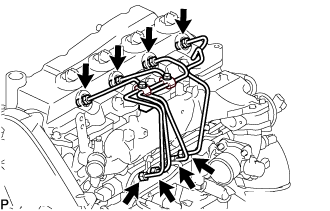

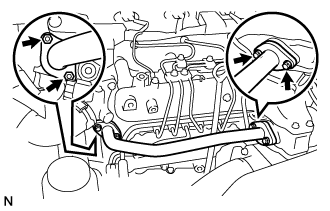

INSTALL FUEL INLET PIPE SUB-ASSEMBLY

Note

-

When replacing the fuel supply pump, common rail, cylinder block, cylinder head, cylinder head gasket, or timing gear case with a new one, replace the fuel inlet pipe.

-

Be careful not to adhere dusts, dirt or any other materials onto the joint area of the fuel inlet pipe.

-

Temporarily install the fuel inlet pipe.

-

Using SST, tighten the injection pipe on the common rail side.

- SST

- 09023-12701

- Torque:

- 32 N*m { 326 kgf*cm, 24 ft.*lbf, for use with SST }

-

Using SST, tighten the injection pipe on the supply pump side.

- SST

- 09023-12701

- Torque:

- 32 N*m { 326 kgf*cm, 24 ft.*lbf, for use with SST }

-

-

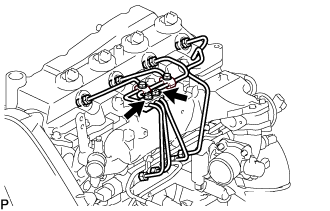

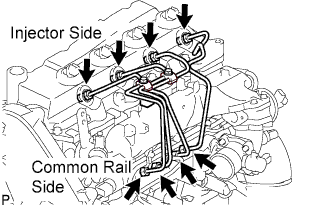

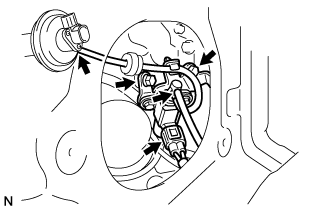

INSTALL INJECTION PIPE

- SST

- 09023-12701

Note

-

When replacing the fuel injector, common rail, or cylinder head with a new one, replace injection pipes No. 1, No. 2, No. 3, and No. 4.

-

Keep clean the joint of the injection pipe.

-

Install the injection pipes.

-

Temporarily install the 4 injection pipes.

-

Install the injection pipe clamp No.3 in 2 nuts.

- Torque:

- 5.0 N*m { 51 kgf*cm, 44 in.*lbf }

-

Fasten the union sequentially, from the injection pipe common rail to the injector, using SST.

- SST

- 09023-12701

- Torque:

- Use union nut wrench and torque wrench

- 32 N*m { 326 kgf*cm, 24 ft.*lbf }

-

-

INSTALL OIL LEVEL GAGE GUIDE

-

Install a new O-ring to the oil level gauge guide.

-

Apply a light coat of engine oil to the O-ring.

-

Install the oil level gauge guide with the bolt.

- Torque:

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

-

Install the oil level gauge.

-

-

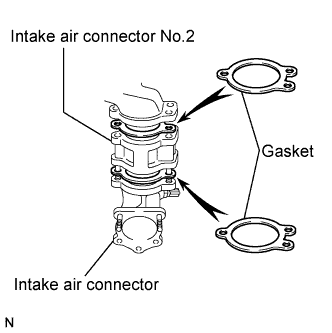

INSTALL INTAKE AIR CONNECTOR (w/o EGR Valve)

-

Temporarily install 2 new gaskets and intake air connector No.2 to the intake air connector.

-

Temporarily tighten the intake air connector assembly with the bolt and 2 nuts.

-

Tighten the manifold stay with the bolt.

-

Tighten the intake air connector with the bolt and 2 nuts.

-

Install the vacuum hose to the intake air connector.

-

-

TEMPORARILY TIGHTEN ELECTRIC EGR CONTROL VALVE ASSEMBLY (w/ EGR Valve)

-

Temporarily tighten the EGR valve assembly with the sensor.

-

Install 2 new gaskets and the EGR valve to the intake air connector as shown in the illustration.

-

Temporarily tighten the intake air connector with EGR valve assembly to the intake manifold with the bolt and the 2 nuts.

-

Install the vacuum hose to the intake air connector.

-

Temporarily tighten the manifold stay with the bolt.

-

Connect the EGR valve position sensor connector.

-

Connect the intake air temperature sensor connector.

-

-

Install the vacuum regulating valve.

-

Install the vacuum regulating valve with the 2 bolts.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

Connect the 2 vacuum hoses and the regulating valve connector.

-

-

-

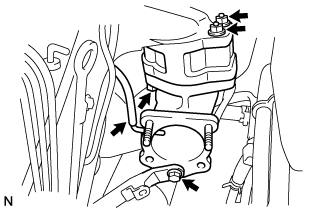

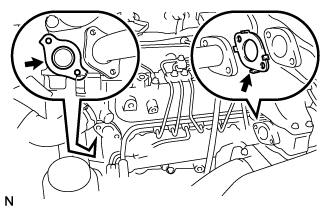

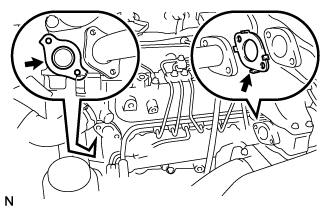

INSTALL EGR PIPE SUB-ASSEMBLY NO.1 (w/ EGR Valve)

-

Install the 2 gaskets to the cylinder head and EGR pipe sub-assembly as shown in the illustration.

-

Install the EGR pipe sub-assembly with the 2 bolts and 2 nuts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Tighten the intake air connector with the bolt and the 2 nuts.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

Tighten the manifold stay.

- Torque:

- 19 N*m { 194 kgf*cm, 14 ft.*lbf }

-

-

REMOVE EGR PIPE SUB-ASSEMBLY NO.1 (w/ EGR Valve)

-

Remove the 3 bolts, the 2 nuts, and the EGR pipe sub-assembly.

-

Remove the 2 gaskets.

-

-

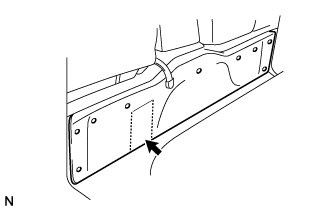

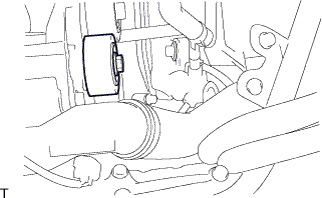

INSTALL ENGINE SERVICE HOLE COVER NO.2

-

Install the engine service hole cover No.2 with the 3 bolts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Return the carpet.

-

-

INSTALL DIESEL THROTTLE BODY ASSEMBLY

Note

After removing and installing, or replacing the throttle body, be sure to perform the operation check.

-

Install a new gasket to intake air connector.

-

Install the throttle body with the 2 bolts and the 2 nuts.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

Connect the 2 throttle body connectors.

-

-

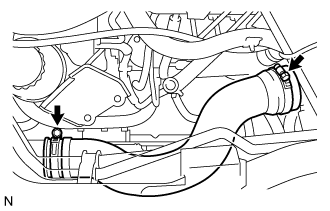

INSTALL AIR HOSE NO.4

-

Install the air hose No.4 with the 2 clamps.

- Torque:

- 6.0 N*m { 61 kgf*cm, 53 in.*lbf }

-

-

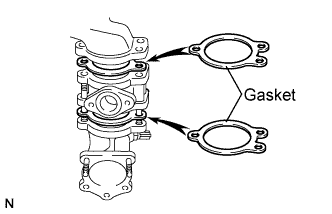

INSTALL EGR PIPE SUB-ASSEMBLY NO.1 (w/ EGR Valve)

-

Install 2 new gaskets to the cylinder head and the EGR pipe sub-assembly No.1 as shown in the illustration.

-

Install the EGR pipe with the 2 bolts and the 2 nuts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Connect the fuel pressure sensor connector.

-

-

INSTALL OIL RETURN HOSE (w/ Intercooler)

-

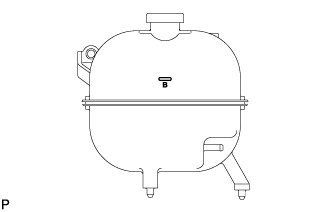

INSTALL VANE PUMP OIL RESERVOIR ASSEMBLY

-

Install the vane pump oil reservoir assembly with the 2 bolts.

- Torque:

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

-

-

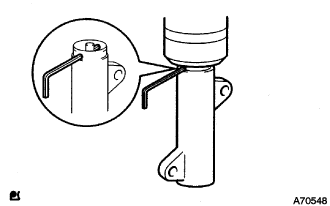

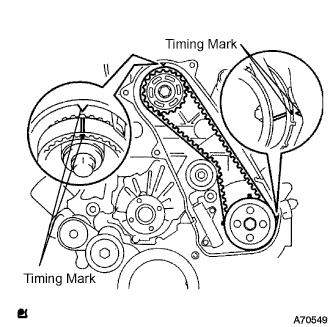

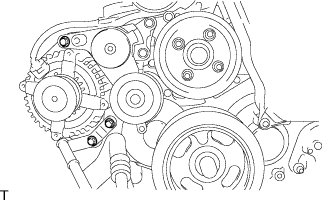

INSTALL TIMING BELT

-

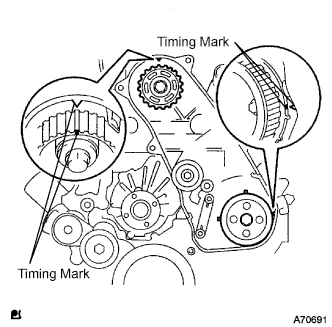

Check that the timing marks are aligned as shown in the illustration.

-

Install the timing belt to pump drive shaft pulley, camshaft timing pulley and timing belt idler No.1 in sequence.

-

Set the tensioner to the press upright.

Note

-

Do not allow the rod end to scratch and deform.

-

Press the tensioner rod in upward.

-

Protect a tip of the push rod with a rag in order to prevent damage.

-

-

Using a press, slowly apply 981 to 9,807 N (100 to 1,000 kgf, 220 to 2,205 lbf) of force to the push rod.

Note

Do not apply loads 981 to 9,807 N (100 to 1,000 kgf, 220 to 2,205 lbf) or more on the push rod.

-

Align the holes of push rod and housing, pass a 1.27 mm hexagon wrench through the holes to keep the setting position of the push rod.

-

Temporarily install the timing belt tensioner with the 2 bolts while pushing the idler pulley toward the timing belt.

-

Tighten the 2 bolts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

Note

Uniformly tighten the 2 bolts and install the tensioner

-

Remove the 1.5 mm hexagon wrench from the tensioner.

-

Turn the crankshaft in the clockwise direction twice, check that the timing marks are aligned as shown in the illustration.

-

-

INSTALL TIMING BELT COVER NO.1

-

Install the timing belt No.1 cover with the 6 bolts.

- Torque:

- 6.0 N*m { 61 kgf*cm, 53 in.*lbf }

-

Install the wire harness clamp.

-

-

INSTALL FAN PULLEY

-

Install the fan pulley with the 4 bolts.

- Torque:

- 23 N*m { 235 kgf*cm, 17 ft.*lbf }

-

-

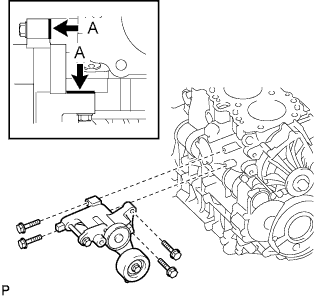

INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

-

Temporarily install the V-ribbed belt tensioner with the 4 bolts.

Tech Tips

Make sure that the V-ribbed belt tensioner is in contact with the engine block at points A shown in the illustration.

-

Tighten the V-ribbed belt tensioner with the 4 bolts.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

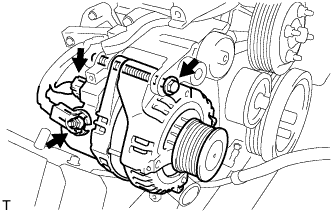

INSTALL GENERATOR ASSEMBLY

-

Install the generator assembly with the bolt.

- Torque:

- 62 N*m { 632 kgf*cm, 46 ft.*lbf }

-

Install the generator wire to terminal B with the nut.

- Torque:

- 9.8 N*m { 100 kgf*cm, 87 in.*lbf }

-

Install the terminal cap.

-

Connect the generator connector.

-

-

INSTALL GENERATOR BRACKET

-

Install the generator bracket with the 2 bolts.

- Torque:

- 36 N*m { 367 kgf*cm, 27 ft.*lbf }

-

-

INSTALL IDLE PULLEY ASSEMBLY (w/ Air Conditioning System)

-

Install the idle No.2 pulley assembly and washer with the bolt.

- Torque:

- 45 N*m { 459 kgf*cm, 33 ft.*lbf }

-

-

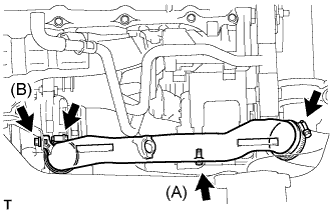

INSTALL COMPRESSOR OUTLET ELBOW

-

Install the compressor outlet elbow with the 2 bolts and 2 clamps.

- Torque:

- Bolt (A)

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

- Bolt (B)

- 32 N*m { 326 kgf*cm, 24 ft.*lbf }

-

-

INSTALL AIR CLEANER HOSE ASSEMBLY

-

Install the air cleaner hose assembly with the clamp.

-

-

INSTALL AIR TUBE ASSEMBLY

-

Install the air tube assembly with the 2 clamps and 2 bolts.

-

-

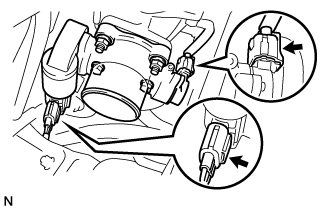

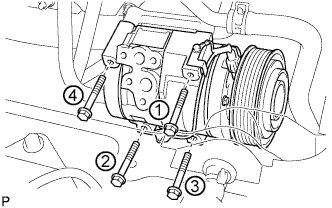

INSTALL COMPRESSOR AND MAGNETIC CLUTCH (w/ Air Conditioning System)

-

Provisionally tighten the compressor and magnetic clutch with the 4 bolts.

-

Tighten the compressor and magnetic clutch with the 4 bolts.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

Note

Tighten the bolts in the order shown in the illustration to install the compressor and magnetic clutch.

-

-

INSTALL FAN & GENERATOR V BELT

-

Rotate the V-ribbed belt tensioner pulley clockwise, and then install the fan and generator V belt.

Note

Make sure that the fan and generator V belt is set properly on each pulley.

-

Check that the indicator mark of the V-ribbed belt tensioner Click here.

-

-

INSTALL FENDER APRON MUDGUARD SEAL RH

-

INSTALL ENGINE SERVICE HOLE SUB COVER SUB-ASSEMBLY

-

Install the engine service hole sub cover with the 5 bolts.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

-

CONNECT BATTERY NEGATIVE CABLE

-

INSTALL FRONT SEAT ASSEMBLY RH (for Hi-back Seat Type)

Tech Tips

Perform the same procedure as RH side on the LH side.

-

INSTALL FRONT SEAT ASSEMBLY RH (for Low-back Seat Type)

Tech Tips

Perform the same procedure as RH side on the LH side.

-

INSTALL FRONT DOOR SCUFF PLATE RH

-

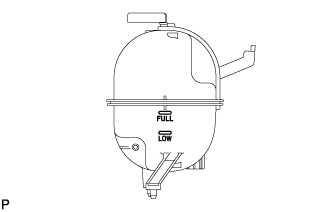

ADD ENGINE COOLANT

-

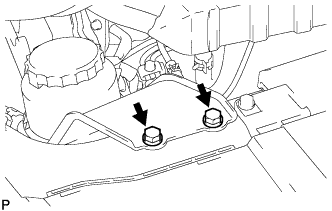

Firmly tighten the drain plugs.

-

Fill the radiator reservoir assembly with engine coolant to the top of the inlet.

Standard Capacity Item Specified Condition w/o Heater 13.2 liters (13.9 US qts, 11.6 Imp. qts) w/ Front Heater 14.2 liters (15.0 US qts, 12.5 Imp. qts) w/ Front and Rear Heaters 16.2 liters (17.1 US qts, 14.3 Imp. qts) Note

Do not substitute plain water for engine coolant.

Tech Tips

-

Use of improper coolants may damage the engine cooling system.

-

Use only Toyota Super Long Life Coolant or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, and non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology consists of a combination of low phosphates and organic acids).

-

-

Loosen the bleeder plug of the outlet housing.

-

When air is bled and the engine coolant drains out, firmly tighten the bleeder plug.

- Torque:

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

-

Add engine coolant up to the B line mark in the radiator reservoir assembly and install the radiator reservoir cap sub-assembly.

-

Warm up the engine until the thermostat opens.

-

While the thermostat is open, circulate the engine coolant for several minutes.

Tech Tips

The thermostat open timing can be confirmed by pressing the No. 3 radiator hose by hand, and checking when the engine coolant starts to flow inside the hose.

-

-

After the engine cools down, check that the engine coolant level is between the LOW and FULL level marks.

-

-

CHECK FOR ENGINE COOLANT LEAKAGE

CAUTION:

Do not remove the radiator cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

-

Fill the radiator with coolant and attach a radiator cap tester to the radiator.

-

Warm up the engine.

-

Using a radiator cap tester, increase the pressure inside the radiator to 137 kPa (1.4 kgf/cm2, 19.9 psi), and check that the pressure does not drop.

Tech Tips

If the pressure drops, check the hoses, radiator or water pump for leaks. If no external leaks are found, check the heater core, cylinder block and cylinder head.

-

-

INSTALL ENGINE UNDER COVER NO.1