SFI SYSTEM, Diagnostic DTC:P0011/59, P0012/59

| DTC Code | DTC Name |

|---|---|

| P0011/59 | Camshaft Position "A" - Timing Over-Advanced or System Performance (Bank 1) |

| P0012/59 | Camshaft Position "A" - Timing Over-Retarded (Bank 1) |

DESCRIPTION

Refer to DTC P0010/39 Click here.

| DTC No. | DTC Detection Condition | Suspected Area |

|---|---|---|

| P0011/59 | Advanced cam timing: After engine is warmed up, valve timing does not change from current valve timing while driving at engine speed of 500 to 4,000 rpm (1 trip detection logic) |

|

| P0012/59 | Retarded cam timing: After engine is warmed up, valve timing does not change from current valve timing while driving at engine speed of 500 to 4,000 rpm (2 trip detection logic) |

|

MONITOR DESCRIPTION

The ECM optimizes the valve timing using the VVT system to control the intake valve camshaft. The VVT system includes the ECM, OCV and VVT actuator. The ECM sends a target "duty-cycle" control signal to the OCV. This control signal, applied to the OCV, regulates the oil pressure supplied to the VVT controller. The VVT controller can advance or retard the intake valve camshaft.

Example:

A DTC will set if: 1) the difference between the target and actual valve timing is more than 5° of the Crankshaft Angle (CA) and the condition continues for more than 4.5 seconds; or 2) the OCV is forcibly activated 63 times or more.

DTC P0011/59 (advanced cam timing) is subject to 1 trip detection logic.

DTC P0012/59 (retarded cam timing) is subject to 2 trip detection logic.

The monitor runs if all the conditions below are met:

-

After warming up engine (engine coolant temperature 75°C (167°F) or more).

-

After driving the vehicle over 40 km/h (25 mph) for 3 minutes.

-

After idling the engine for 3 minutes.

WIRING DIAGRAM

Refer to DTC P0010/39 Click here.

INSPECTION PROCEDURE

Tech Tips

| Condition | DTC |

|---|---|

| Advanced timing over (valve timing is out of specified range) |

P0011/59 |

| Retarded timing over (valve timing is out of specified range) |

P0012/59 |

-

If DTC P0011/59 or P0012/59 is present, check the VVT system circuit.

-

Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

Note

DTC P0011/59 or P0012/59 is output when a foreign object in the engine oil enters the system. These codes will stay even if the system returns to normal after a short time. Foreign objects are filtered out by the oil filter.

When using intelligent tester:

PROCEDURE

-

PERFORM ACTIVE TEST (OPERATE OCV)

-

Start and warm up the engine.

-

Turn the ignition switch OFF.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch ON and turn the intelligent tester ON.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Activate the VVT System (Bank 1).

-

Using the intelligent tester, operate the OCV and check the engine speed.

OK Tester Operation Specified Condition OCV is OFF Normal engine speed OCV is ON Rough idle or engine stall

NG

CHECK VALVE TIMING Click here

OK

-

-

CHECK IF DTC OUTPUT RECURS (DTC P0011/59 OR P0012/59)

-

Clear the DTCs using the intelligent tester Click here.

-

Start the engine and warm it up.

-

Drive the vehicle for 10 minutes or more.

-

Read output DTC using the intelligent tester.

OK No DTC output.

OK

VVT SYSTEM OK

NG

-

-

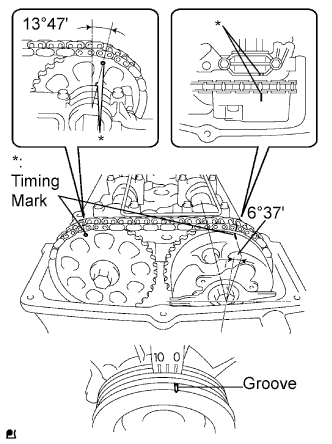

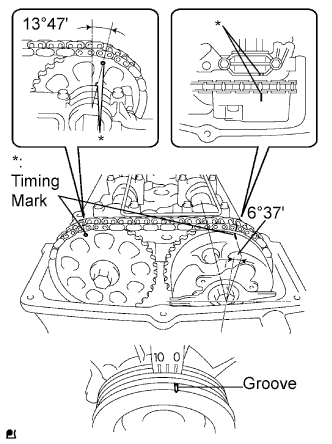

CHECK VALVE TIMING

-

Remove the cylinder head cover.

-

Turn the crankshaft to align the timing marks of the crankshaft.

-

Align the groove of the crankshaft pulley with the "0" position.

-

Confirm whether the timing marks of the camshaft pulley and cylinder head cover are facing each other.

-

If the timing marks are not facing each other, turn the crankshaft clockwise by 360°. Confirm again if the timing marks are facing each other.

OK The timing marks of the camshaft pulley and the cylinder head cover face each other when the groove of the crankshaft pulley is in the "0" position.

NG

ADJUST VALVE TIMING

OK

-

-

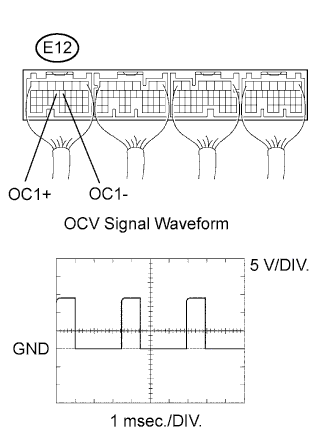

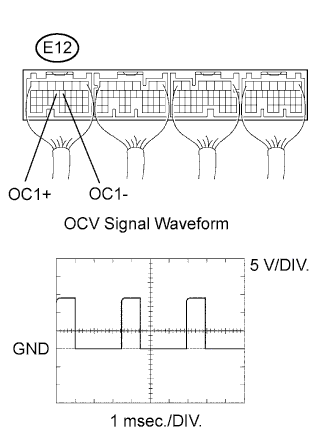

CHECK ECM (OCV SIGNAL)

-

While idling, check the waveform of the ECM connector using the oscilloscope.

OK Tester Connection Specified Condition E12-13 (OC1+) - E12-12 (OC1-) Correct waveform is as shown Tool setting 5 V/DIV., 1 msec./DIV. Condition Accelerate slowly after engine warm-up

NG

REPLACE ECM

OK

-

-

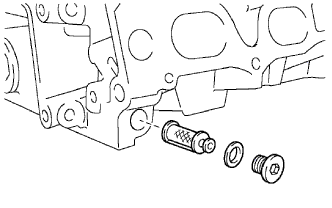

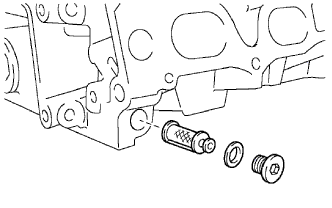

CHECK OIL CONTROL VALVE FILTER

-

Remove the OCV filter.

-

Check that the filter is not clogged.

OK The filter is not clogged.

NG

REPLACE OIL CONTROL VALVE FILTER

OK

-

-

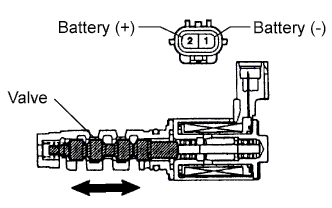

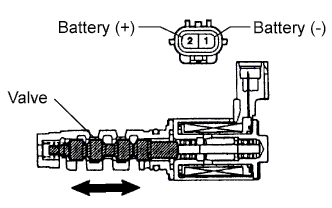

INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV)

-

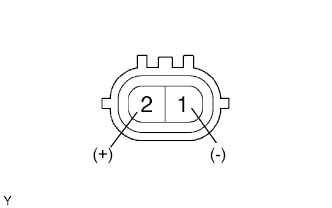

Measure the resistance between the terminals of the OCV.

Standard 6.9 to 7.9 Ω at 20°C (68°F) -

Remove the OCV.

-

Apply positive (+) battery voltage to terminal 2 and negative (-) battery voltage to terminal 1. Check the valve operation.

OK The valve moves quickly.

OK

CHECK CAMSHAFT TIMING GEAR ASSEMBLY Click here

NG

-

-

REPLACE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV)

NEXT

-

CHECK CAMSHAFT TIMING GEAR ASSEMBLY

OK The camshaft timing gear rotates smoothly when applying pressure.

OK

CHECK FOR BLOCKAGE (OCV, OIL CHECK VALVE, OIL HOLE) Click here

NG

-

REPLACE CAMSHAFT TIMING GEAR ASSEMBLY

NEXT

-

CHECK FOR BLOCKAGE (OCV, OIL CHECK VALVE, OIL HOLE)

OK No blockage.

NG

REPAIR OR REPLACE

OK

-

CHECK IF DTC OUTPUT RECURS (DTC P0011/59 OR P0012/59)

-

Clear the DTCs using the intelligent tester Click here.

-

Start the engine and warm it up.

-

Drive the vehicle for 10 minutes or more.

-

Read output DTC using the intelligent tester.

OK No DTC output.

OK

VVT SYSTEM OK

NG

REPLACE ECM

-

When not using intelligent tester:

Note

DTC P0011/59 or P0012/59 is output when a foreign object in the engine oil enters the system. These codes will stay even if the system returns to normal after a short time. Foreign objects are filtered out by the oil filter.

PROCEDURE

-

CHECK VALVE TIMING

-

Remove the cylinder head cover.

-

Turn the crankshaft to align the timing marks of the crankshaft.

-

Align the groove of the crankshaft pulley with the "0" position.

-

Confirm whether the timing marks of the camshaft pulley and cylinder head cover are facing each other.

-

If the timing marks are not facing each other, turn the crankshaft clockwise by 360°. Confirm again if the timing marks are facing each other.

OK The timing marks of the camshaft pulley and the cylinder head cover face each other when the groove of the crankshaft pulley is in the "0" position.

NG

ADJUST VALVE TIMING

OK

-

-

CHECK ECM (OPERATION OF OCV)

-

Start the engine.

-

Check the engine speed.

-

Disconnect the C14 OCV connector. Check the engine speed.

OK Normal -

Apply positive (+) battery voltage between the terminals of the OCV. Check the engine speed.

OK Rough idle or engine stalls If either or both results are not as specified, proceed to NG.

-

NG

CHECK ECM (OCV SIGNAL) Click here

OK

-

-

CHECK IF DTC OUTPUT RECURS (DTC P0011/59 OR P0012/59)

-

Clear the DTCs.

-

Disconnect the battery terminal or remove the EFI and ETCS fuses for more than 60 seconds.

-

-

Start the engine and warm it up.

-

Drive the vehicle for 10 minutes or more.

-

Read output DTC.

OK No DTC output.

OK

VVT SYSTEM OK

NG

-

-

CHECK ECM (OCV SIGNAL)

-

While idling, check the waveform of the ECM connector using the oscilloscope.

Standard Tester Connection Specified Condition E12-13 (OC1+) - E12-12 (OC1-) Correct waveform is as shown Tool setting 5 V/DIV., 1 msec./DIV. Condition Accelerate slowly after engine warm-up

NG

REPLACE ECM

OK

-

-

CHECK OIL CONTROL VALVE FILTER

-

Remove the OCV filter.

-

Check that the filter is not clogged.

OK The filter is not clogged.

NG

REPLACE OIL CONTROL VALVE FILTER

OK

-

-

CHECK CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV)

-

Measure the resistance between the terminals of the OCV.

Standard 6.9 to 7.9 Ω at 20°C (68°F) -

Remove the OCV.

-

Apply positive (+) battery voltage to terminal 2 and negative (-) battery voltage to terminal 1. Check the valve operation.

OK The valve moves quickly.

OK

CHECK CAMSHAFT TIMING GEAR ASSEMBLY Click here

NG

-

-

REPLACE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (OCV)

NEXT

-

CHECK CAMSHAFT TIMING GEAR ASSEMBLY

OK The camshaft timing gear rotates smoothly when applying pressure.

OK

CHECK FOR BLOCKAGE (OCV, OIL CHECK VALVE, OIL HOLE) Click here

NG

-

REPLACE CAMSHAFT TIMING GEAR ASSEMBLY

NEXT

-

CHECK FOR BLOCKAGE (OCV, OIL CHECK VALVE, OIL HOLE)

OK No blockage.

NG

REPAIR OR REPLACE

OK

-

CHECK IF DTC OUTPUT RECURS (DTC P0011/59 OR P0012/59)

-

Clear the DTCs.

-

Disconnect the battery cable or remove the EFI and ETCS fuses for more than 60 seconds.

-

-

Start and warm up the engine.

-

Drive the vehicle for 10 minutes or more.

-

Read output DTC.

OK No DTC output.

OK

VVT SYSTEM OK

NG

REPLACE ECM

-