AUTOMATIC TRANSAXLE SYSTEM, Diagnostic DTC:P08BA7F

| DTC Code | DTC Name |

|---|---|

| P08BA7F | Pressure Control Solenoid "L" Actuator Stuck Off |

DESCRIPTION

Based on signals from the transmission revolution sensors (NT and NC), the actual gear is detected.

The ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical malfunctions of the solenoid valves, transmission valve body assembly and automatic transaxle assembly (clutch, brake, gear, etc.).

Tech Tips

| ECM commanded gear | 1st | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th |

|---|---|---|---|---|---|---|---|---|

| Actual gear during SL6 stuck ON malfunction | 1st | N* | 3rd | 4th | 5th | 6th | 7th | N* |

| Actual gear during SL6 stuck OFF malfunction | N* | 2nd | 3rd | 4th | 5th | 6th | 7th | 8th |

*: Neutral

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory | Note |

|---|---|---|---|---|---|---|

| P08BA7F | Pressure Control Solenoid "L" Actuator Stuck Off | All of the following conditions are met (2-trip detection logic):

|

|

Comes on | DTC stored | SAE Code: P08BB |

| Vehicle Condition | ||||

|---|---|---|---|---|

| Pattern 1 | Pattern 2 | Pattern 3 | ||

| Diagnostic Condition | Engine coolant temperature is 40°C (104°F) or higher. | ○ | ○ | ○ |

| ATF temperature is -10°C (14°F) or higher. | ○ | ○ | ○ | |

| The vehicle is being driven with the shift lever in D. | ○ | ○ | ○ | |

| No malfunctions are detected in the solenoid (SL1, SL2, SL3, SL4, SL5, SL6, SL, SLU and SLT) valves, transmission revolution sensors (NT and NC), coolant temperature sensor, oil temperature sensor, knock sensor, crankshaft position sensor circuits, electronic throttle or CAN communication system. | ○ | ○ | ○ | |

| Malfunction Condition | When the ECM commands the transaxle to shift to 2nd gear, the engine overruns (neutral status). | ○ | - | - |

| When the ECM commands the transaxle to shift to 8th gear, the engine overruns (neutral status). | - | ○ | - | |

| When the ECM commands the transaxle to shift to 1st gear, the engine overruns (neutral status). | - | - | ○ | |

| Duration | - | - | - | |

| Detection Logic | 2-trip detection logic | 2-trip detection logic | 2-trip detection logic | |

Tech Tips

This DTC is stored when any of the above detection patterns is met.

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the solenoid valves on and off. According to the input shaft revolution (speed) and output shaft revolution (speed), the ECM detects the actual gear (1st, 2nd, 3rd, 4th, 5th, 6th, 7th or 8th gear). When the gear commanded by the ECM and the actual gear are not the same, the ECM illuminates the MIL and stores a DTC.

CONFIRMATION DRIVING PATTERN

CAUTION:

When performing the confirmation driving pattern, obey all speed limits and traffic laws.

Tech Tips

After repairs have been completed, clear the DTCs and then check that the vehicle has returned to normal by performing the following All Readiness check procedure.

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure).

-

Turn the engine switch off and wait for 2 minutes or more.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Start the engine.

-

Perform the D Position Shift Test inspection in Road Test.

-

Stop the vehicle.

-

Enter the following menus: Powertrain / Transmission / Utility / All Readiness.

-

Input the DTC: P08BA7F.

-

Check the DTC judgment result.

GTS Display Description NORMAL

-

DTC judgment completed

-

System normal

ABNORMAL

-

DTC judgment completed

-

System abnormal

INCOMPLETE

-

DTC judgment not completed

-

Perform driving pattern after confirming DTC enabling conditions

N/A

-

Unable to perform DTC judgment

-

Number of DTCs which do not fulfill DTC preconditions has reached ECU memory limit

Tech Tips

-

If the judgment result shows NORMAL, the system is normal.

-

If the judgment result shows ABNORMAL, the system has a malfunction.

-

If the judgment result shows INCOMPLETE or N/A, perform the Confirmation Driving Pattern and check the DTC judgment result again.

-

CAUTION / NOTICE / HINT

Note

Perform registration and/or initialization when parts related to the automatic transaxle are replaced.

PROCEDURE

-

CHECK DTC OUTPUT (IN ADDITION TO DTC P08BA7F)

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Transmission / Trouble Codes.

Powertrain > Transmission > Trouble Codes -

Read the DTCs using the GTS.

Result Result Proceed to DTC P08BA7F and DTC P07407E, P07457F, P07757F, P07957F, P27137F, P28167F and/or P28077F are output A Only DTC P08BA7F is output B DTCs other than P07407E, P07457F, P07757F, P07957F, P08BA7F, P27137F, P28077F and P28167F are also output C Tech Tips

-

If any DTCs other than P07407E, P07457F, P07757F, P07957F, P08BA7F, P27137F, P28077F and P28167F are output, perform troubleshooting for those DTCs first.

-

If a solenoid valve is stuck ON or OFF, DTCs for several solenoid valves including the malfunctioning solenoid valve will be stored.

-

B

GO TO STEP 3 Click here

C

GO TO DTC CHART Click here

A

-

-

CLEAR DTC AND PERFORM STALL SPEED TEST

-

Clear the DTCs.

Powertrain > Transmission > Clear DTCsTech Tips

Write down the currently output DTCs before clearing them.

-

Perform the stall speed test.

Result Test Condition Proceed to Stall speed test can be performed A Stall speed test cannot be performed B

B

GO TO STEP 5 Click here

A

-

-

INSPECT SOLENOID (SL1), (SL2), (SL3), (SL4), (SL5) AND (SL6) VALVE

-

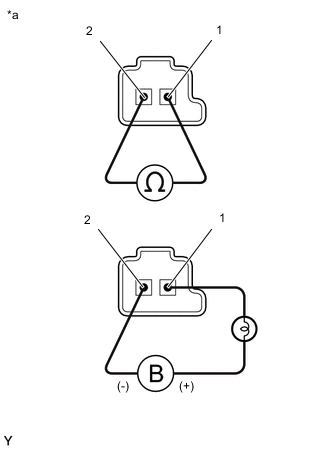

*a Component without harness connected

(Solenoid (SL1), (SL2), (SL3), (SL4), (SL5) and (SL6) Valves)

Remove the solenoid (SL1), (SL2), (SL3), (SL4), (SL5) and (SL6) valves.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition Solenoid (SL1) valve connector terminal 1 - terminal 2 20°C (68°F) 5.0 to 5.6 Ω Solenoid (SL2) valve connector terminal 1 - terminal 2 20°C (68°F) 5.0 to 5.6 Ω Solenoid (SL3) valve connector terminal 1 - terminal 2 20°C (68°F) 5.0 to 5.6 Ω Solenoid (SL4) valve connector terminal 1 - terminal 2 20°C (68°F) 5.0 to 5.6 Ω Solenoid (SL5) valve connector terminal 1 - terminal 2 20°C (68°F) 5.0 to 5.6 Ω Solenoid (SL6) valve connector terminal 1 - terminal 2 20°C (68°F) 5.0 to 5.6 Ω -

Connect a positive (+) lead from the battery with a 21 W bulb to terminal 1 and a negative (-) lead to terminal 2 of the solenoid valve connector. Check that the valve moves and makes an operating sound.

OK Valve moves and makes an operating sound. Result Proceed to OK NG

NG

REPLACE SOLENOID (SL1), (SL2), (SL3), (SL4), (SL5) OR (SL6) VALVE Click here

OK

-

-

INSPECT SOLENOID (SL) VALVE

-

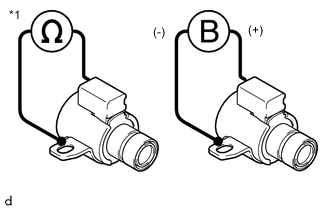

*1 Solenoid (SL) Valve Remove the solenoid (SL) valve.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition Solenoid (SL) valve connector terminal - Solenoid (SL) valve body 20°C (68°F) 11 to 15 Ω -

Connect a positive (+) lead from the battery to the terminal of the solenoid valve connector, and a negative (-) lead to the solenoid body. Check that the valve moves and makes an operating sound.

OK Valve moves and makes an operating sound. Result Proceed to OK NG

NG

REPLACE SOLENOID (SL) VALVE Click here

OK

-

-

INSPECT SOLENOID (SLT) VALVE

-

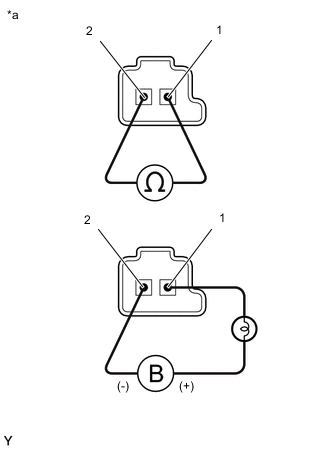

*a Component without harness connected

(Solenoid (SLT) Valve)

Remove the solenoid (SLT) valve.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition Solenoid (SLT) valve connector terminal 1 - terminal 2 20°C (68°F) 5.0 to 5.6 Ω -

Connect a positive (+) lead from the battery with a 21 W bulb to terminal 1 and a negative (-) lead to terminal 2 of the solenoid valve connector. Check that the valve moves and makes an operating sound.

OK Valve moves and makes an operating sound. Result Proceed to OK NG

NG

REPLACE SOLENOID (SLT) VALVE Click here

OK

-

-

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

-

Inspect the transmission valve body assembly.

OK There is no foreign matter on each valve and they operate smoothly. Result Proceed to OK NG

NG

REPAIR OR REPLACE TRANSMISSION VALVE BODY ASSEMBLY Click here

OK

-

-

INSPECT TORQUE CONVERTER ASSEMBLY

-

Inspect the torque converter assembly.

OK The torque converter assembly is normal. Result Proceed to OK NG

NG

REPAIR OR REPLACE TORQUE CONVERTER ASSEMBLY Click here

OK

-

-

REPAIR OR REPLACE AUTOMATIC TRANSAXLE ASSEMBLY

-

Repair or replace the automatic transaxle assembly.

Result Proceed to NEXT

NEXT

PERFORM REGISTRATION Click here

-