CONTINUOUSLY VARIABLE TRANSAXLE SYSTEM(for 1ZR-FAE), Diagnostic DTC:P282B

| DTC Code | DTC Name |

|---|---|

| P282B | Pressure Control Solenoid "K" Electrical (Shift Solenoid Valve SLS) |

DESCRIPTION

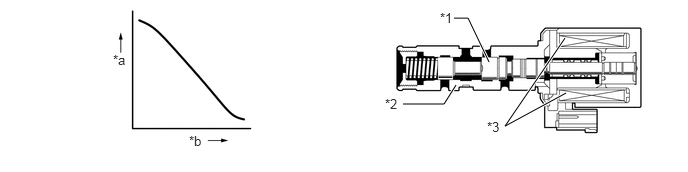

According to current from the ECM, the shift solenoid valve SLS controls secondary pulley pressure and belt clamping pressure in accordance with the input shaft torque.

*1 |

Spool Valve |

*2 |

Sleeve |

*3 |

Solenoid Coil |

- |

- |

*a |

Hydraulic Pressure |

*b |

Current Flow to Solenoid |

DTC No. |

Detection Item |

DTC Detection Condition |

Trouble Area |

MIL |

Memory |

|---|---|---|---|---|---|

P282B |

Pressure Control Solenoid "K" Electrical (Shift Solenoid Valve SLS) |

1. Diagnosis Condition 2. Malfunction Status 3. Malfunction Time 4. Other

|

|

Comes on |

DTC stored |

MONITOR DESCRIPTION

This DTC indicates an open or short in the shift solenoid valve SLS circuit. If there is an open or short in the shift solenoid valve SLS circuit, the ECM detects the malfunction, illuminates the MIL and stores this DTC.

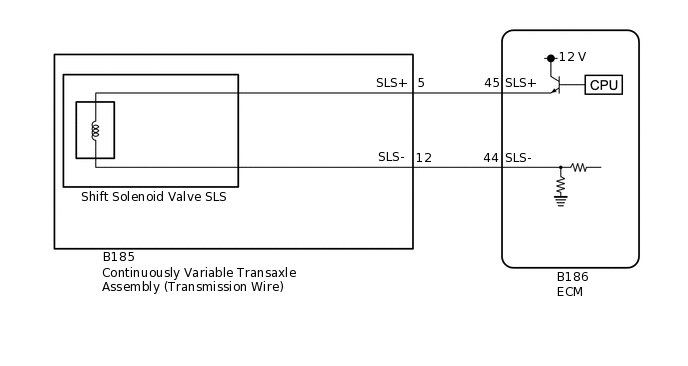

WIRING DIAGRAM

CAUTION / NOTICE / HINT

After performing repair, clear the DTCs and perform the following procedure to check that DTCs are not output.

Perform the D position test in Road Test.

Check for DTCs again.

PROCEDURE

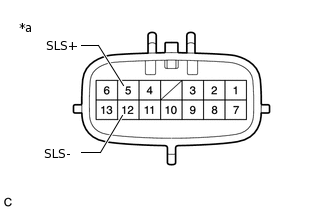

INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE SLS)

-

*a

Component without harness connected

(Transmission Wire)

Disconnect the B185 transmission wire connector.

Measure the resistance according to the value(s) in the table below.

Standard Resistance

Tester Connection

Condition

Specified Condition

5 (SLS+) - 12 (SLS-)

20°C (68°F)

5.0 to 5.6 Ω

5 (SLS+) - Body ground and other terminals

Always

10 kΩ or higher

12 (SLS-) - Body ground and other terminals

Always

10 kΩ or higher

Connect the B185 transmission wire connector.

Result

Proceed to

OK

NG

NG REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLYClick here

-

CHECK HARNESS AND CONNECTOR (TRANSMISSION WIRE - ECM)

Disconnect the B186 ECM connector.

Measure the resistance according to the value(s) in the table below.

Standard Resistance

Tester Connection

Condition

Specified Condition

B186-45 (SLS+) - B186-44 (SLS-)

20°C (68°F)

5.0 to 5.6 Ω

B186-45 (SLS+) - Body ground and other terminals

Always

10 kΩ or higher

B186-44 (SLS-) - Body ground and other terminals

Always

10 kΩ or higher

Connect the B186 ECM connector.

Result

Proceed to

OK

NG

NG REPAIR OR REPLACE HARNESS OR CONNECTOR (TRANSMISSION WIRE - ECM)

REPLACE ECM

Replace the ECM.

Result

Proceed to

NEXT

REPLACE CONTINUOUSLY VARIABLE TRANSAXLE ASSEMBLY

Replace the continuously variable transaxle assembly.

Result

Proceed to

NEXT