SFI SYSTEM

-

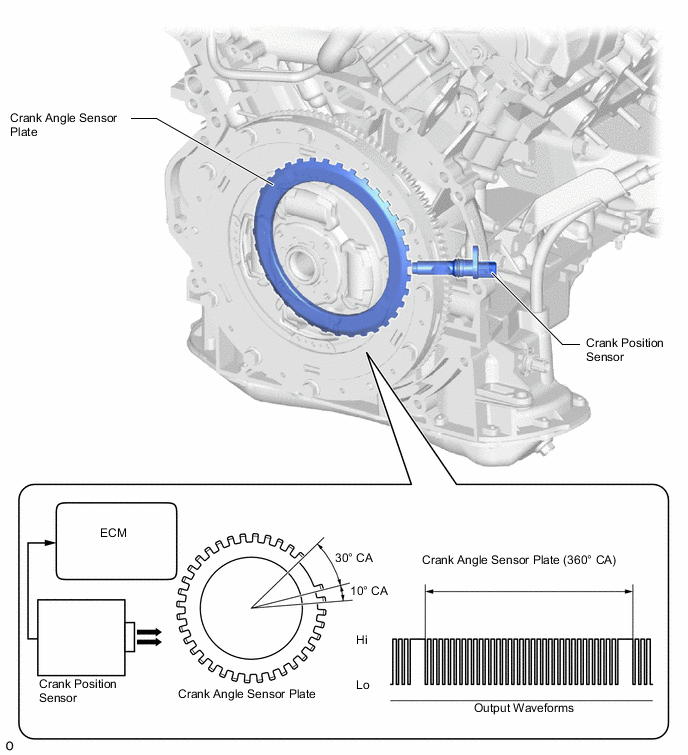

CONSTRUCTION

-

A Magnetic Resistance Element (MRE) type crank position sensor is used to detect the engine speed and crankshaft angle.

-

The crank angle sensor plate (timing rotor) of the crankshaft consists of 34 teeth with 2 teeth missing. The crank position sensor outputs a crankshaft rotation signal every 10°, and the change of the signal due to the missing teeth is used to determine top-dead-center.

-

An MRE type crank position sensor consists of an MRE, a magnet and a sensor. The direction of the magnetic field changes due to the profile (protruding and non-protruding portions) of the crank angle sensor plate, which passes by the sensor. As a result, the resistance of the MRE changes, and the output voltage to the ECM changes to high or low. The ECM detects the crankshaft position based on this output voltage.

-

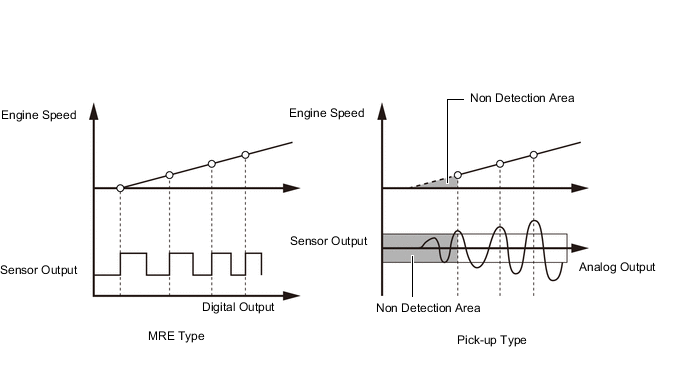

The differences between a MRE type sensor and the pick-up coil type sensor used on the conventional models are as follows:

-

The MRE type sensor outputs a constant level of high and low digital signals regardless of the engine speed. Therefore, the MRE type sensor can detect the positions of the crankshaft.

-

The pick-up coil type sensor outputs analog signals with levels that change with the engine speed.

Figure 1. MRE Type and Pick-up Coil Type Output Waveform Image Comparison

-

-