ENGINE UNIT

-

CONSTRUCTION

-

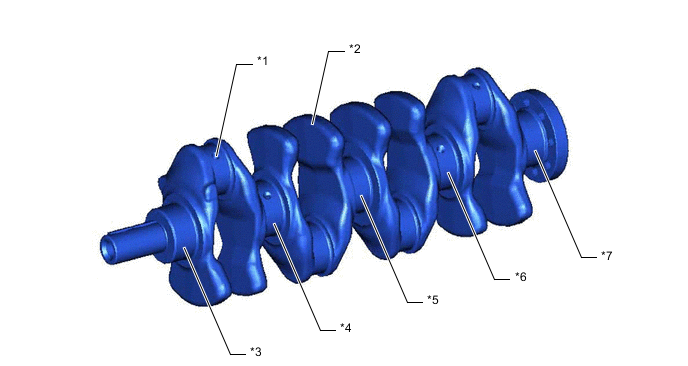

The crankshaft has 5 main journals and 8 balance weights.

-

The pins and journals have been machined with increased precision and the surface roughness has been minimized to reduce friction.

*1 Oil Hole *2 Balance Weight *3 No. 1 Journal *4 No. 2 Journal *5 No. 3 Journal *6 No. 4 Journal *7 No. 5 Journal - - -

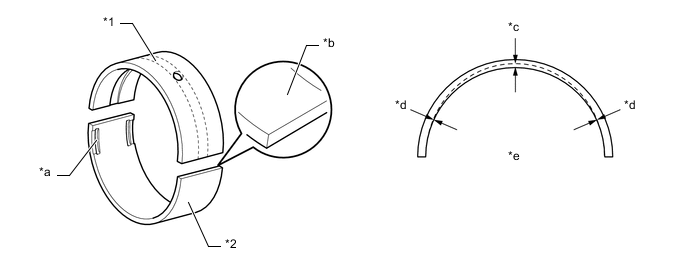

The width of the crankshaft bearings has been optimized to reduce friction.

-

The lining surface of the crankshaft bearing is resin coated to provide an optimal oil clearance. As a result, cold-engine cranking performance has been improved and engine vibration has been reduced.

-

An oil groove is provided on each upper main bearing (crankshaft bearing). The oil groove is deep at the center and is shallow at the edges to reduce the amount of oil that will leak from the crankshaft bearing. As a result, the size of the oil pump has been reduced, thus minimizing friction.

-

Narrow grooves have added to the lower side of the crankshaft bearing to prolong the length of time the oil stays in the bearing and to increase the oil temperature at an earlier stage. Thus, friction has been decreased even when the crankshaft is cold.

*1 Upper Main Bearing (Crankshaft Bearing) *2 Lower Main Bearing (Crankshaft Bearing) *a Narrow Groove *b Resin Coating *c Center *d Edge *e Oil Groove Depth - -

-