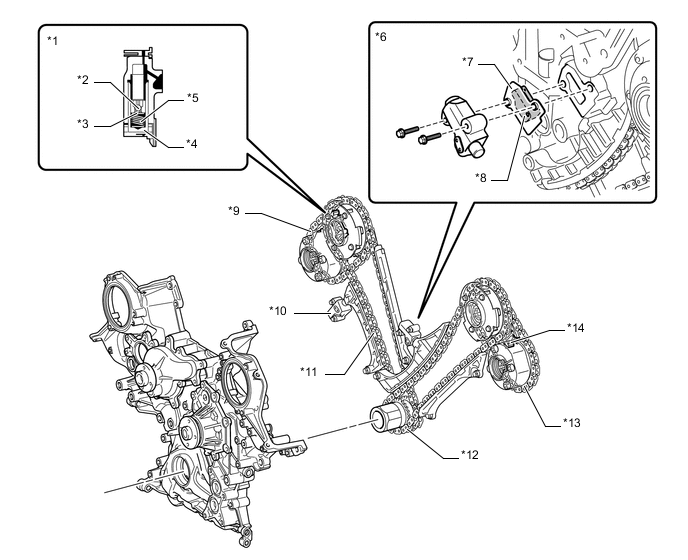

ENGINE UNIT

-

CONSTRUCTION

-

The chain sub-assemblies and No. 2 chain sub-assemblies are roller chains with a pitch of 9.525 mm (0.375 in.).

-

A chain tensioner assembly is provided for each chain sub-assembly and No. 2 chain sub-assembly on each bank.

-

The No. 1, No. 2 and No. 3 chain tensioner assemblies use a spring and oil pressure to maintain proper chain tension at all times. The tensioners suppress noise generated by the timing chains.

-

The No. 1 chain tensioner assembly is a ratchet type tensioner with a non-return mechanism. Furthermore, the chain tensioner gasket is provided with an oil pocket. The pocket reduces the time it takes for oil pressure to build up in the No. 1 chain tensioner assembly when the engine is started. This prevents the timing chain from flapping and reduces noise.

*1 No. 2 Chain Tensioner Assembly *2 Ball *3 Ball Spring *4 Plunger *5 Main Spring *6 No. 1 Chain Tensioner Assembly (LH) *7 Chain Tensioner Gasket *8 Oil Pocket *9 No. 2 Chain Sub-assembly (RH) *10 No. 1 Chain Tensioner Assembly (RH) *11 Chain Sub-assembly (RH) *12 Chain Sub-assembly (LH) *13 No. 2 Chain Sub-assembly (LH) *14 No. 3 Chain Tensioner Assembly

-