ENGINE UNIT

-

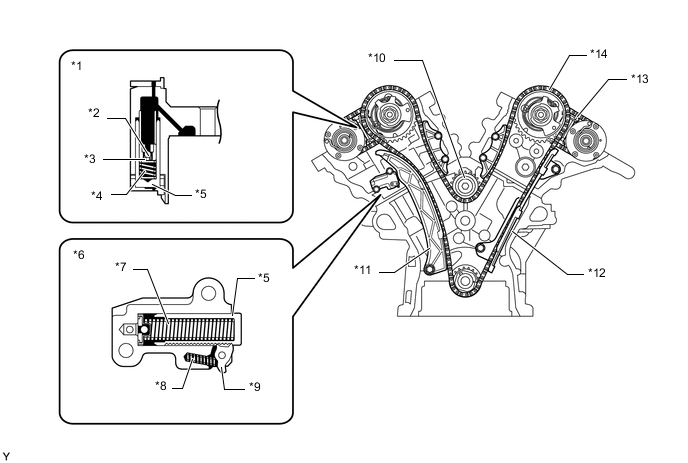

CONSTRUCTION

-

A low-friction timing chain is used, reducing friction. In order to reduce emissions, a simplex roller chain (9.525 mm pitch) is used, which improves resistance to wear and elongation and increases valve timing precision

-

Resin materials with high friction reducing efficiency and wear resistance are used on portions of the chain slipper and chain damper where the timing chain slides. Also, resin is used for the base portion of the chain slipper, achieving weight reduction.

-

The No. 1 chain tensioner sub-assembly uses both hydraulic pressure and spring force to constantly apply the appropriate amount of tension to the chain, ensuring quietness and reliability. Also, a ratchet mechanism is used to ensure quietness at startup.

-

The No. 2 and No. 3 chain tensioner sub-assemblies are positioned between the intake and exhaust sides in order to suppress chain vibrations, ensuring quietness and reliability.

-

Rubber is installed to the bottom lands of the idler sprocket to ensure quietness.

*1 No. 2 or No. 3 Chain Tensioner Sub-assembly *2 Check Ball *3 Ball Spring *4 Main Spring *5 Plunger *6 No. 1 Chain Tensioner Sub-assembly *7 Spring *8 Cam Spring *9 Cam *10 Idle Sprocket Assembly *11 No. 1 Chain Slipper *12 No. 1 Chain Damper *13 No. 2 Chain Sub-assembly *14 No. 1 Chain Sub-assembly

-