LUBRICATION SYSTEM DETAILS

-

CONSTRUCTION

-

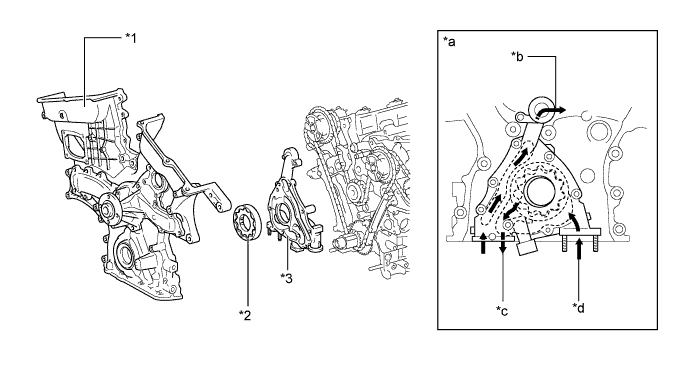

Oil Pump

-

A compact cycloid rotor type oil pump directly driven by the crankshaft is used.

-

This oil pump uses an internal relief method which circulates relief oil to the suction passage in the oil pump. This aims to minimize oil level change in the oil pan, reduce friction, and reduce the air mixing rate in the oil.

Text in Illustration *1 Timing Chain Cover Sub-assembly *2 Oil Pump Rotor (Cycloid Rotor) *3 Oil Pump Cover - - *a Oil Passage in the Oil Pump *b to Cylinder Block Sub-assembly *c to Oil Filter *d from Oil Strainer Sub-assembly

-

-

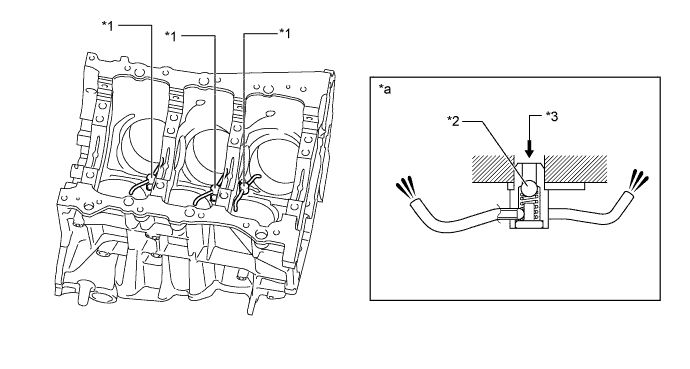

No. 1 Oil Nozzle Sub-assembly

-

No. 1 oil nozzle sub-assemblies are provided in the center of the right and left banks of the cylinder block for cooling and lubricating the pistons.

-

These No. 1 oil nozzle sub-assemblies contain a check valve to prevent oil from being fed when the oil pressure is low. This prevents the overall oil pressure in the engine from dropping.

Text in Illustration *1 No. 1 Oil Nozzle Sub-assembly *2 Check Ball *3 Oil - - *a No. 1 Oil Nozzle Sub-assembly Cross Section - -

-

-

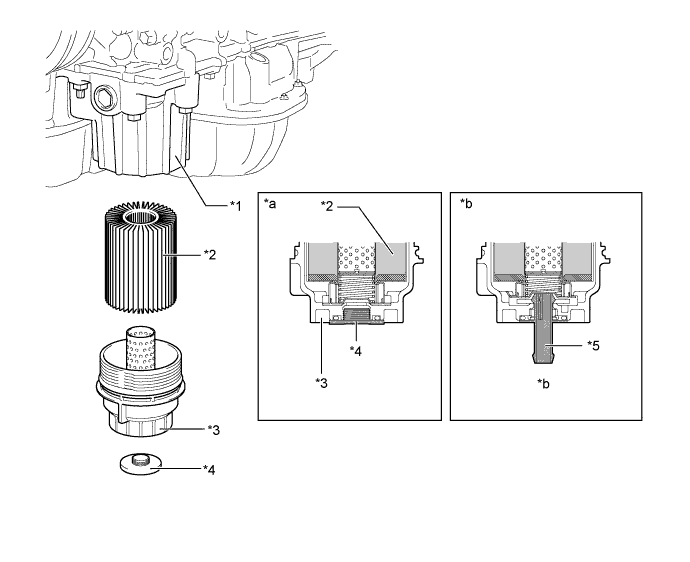

Oil Filter

-

An oil filter with a replaceable oil filter element is used. The oil filter element uses a high-performance filter paper to improve filtration performance. It is also combustible for environmental protection.

-

An aluminum alloy filter cap sub-assembly is used to extend its life.

-

This oil filter has a structure which can allow the draining of the oil remaining in the oil filter. This prevents oil from spattering when replacing the oil filter element and allows the technician to work without touching hot oil.

Text in Illustration *1 Oil Filter Case *2 Oil filter Element *3 Filter Cap Sub-assembly *4 Drain Plug *5 Drain Pipe - - *a Cross section *b When Draining Oil

-

-