INTAKE SYSTEM

-

CONSTRUCTION

-

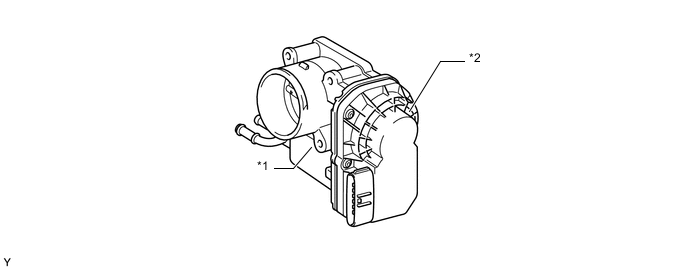

Diesel Throttle Body

-

A linkless-type diesel throttle body is used, achieving excellent throttle control.

-

A DC motor with excellent response and minimal power consumption is used for the throttle control motor. The ECM performs the duty ratio control of the direction and the amperage of the current that flows to the throttle control motor in order to regulate the opening angle of the throttle valve.

Text in Illustration *1 Throttle Control Motor *2 Throttle Position Sensor

-

-

Turbocharger Sub-assembly

-

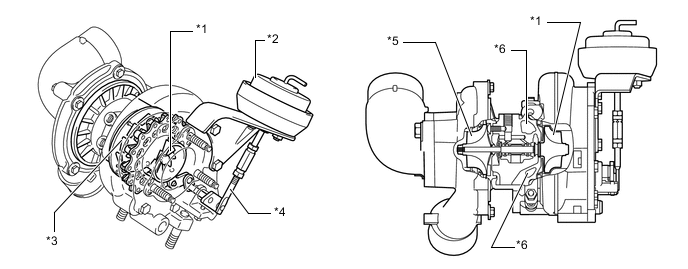

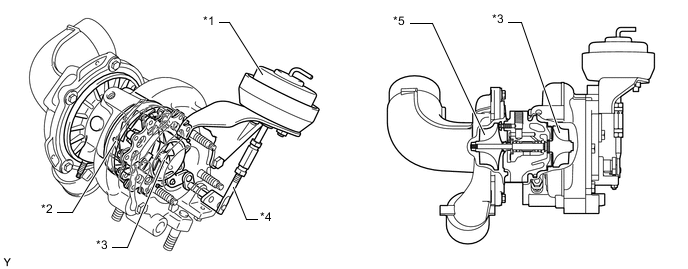

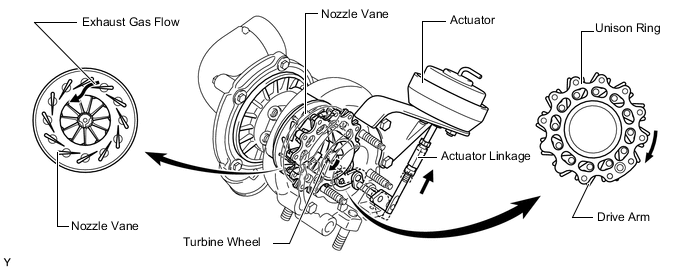

The variable nozzle vane type turbocharger sub-assembly drives the vacuum type actuator according to engine condition, and controls the nozzle vane in order to achieve high engine output, low fuel consumption and low emissions.

-

On models with automatic transaxle, the turbocharger sub-assembly is cooled by the engine oil. On models with manual transaxle, the turbocharger sub-assembly is cooled by the engine oil and the engine coolant.

Text in Illustration (Models with Manual Transaxle) *1 Turbine Wheel *2 Actuator *3 Nozzle Vane *4 Actuator Linkage *5 Impeller Wheel *6 Water Jacket

Text in Illustration (Models with Automatic Transaxle) *1 Actuator *2 Nozzle Vane *3 Turbine Wheel *4 Actuator Linkage *5 Impeller Wheel - - -

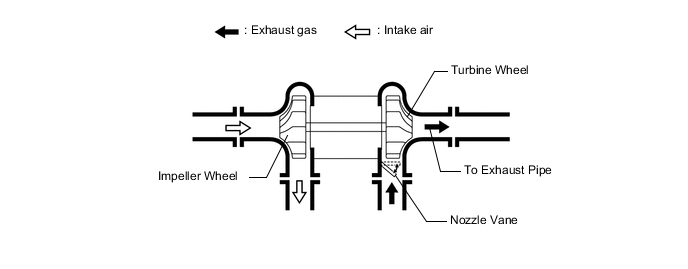

The exhaust gas from the exhaust manifold goes through the nozzle vane inside the turbocharger housing, and flows to the exhaust pipe through the turbine. The speed of the turbine (supercharging pressure) differs depending on the flow velocity of the exhaust gas going through the turbine. The flow velocity of the exhaust gas is controlled by the opening. When idling and so forth, the exhaust gas is reduced and the nozzle vane is fully closed, but as there is a slight clearance between the vanes, the exhaust gas flows through this clearance to the exhaust pipe. As this type of turbocharger has a nozzle vane which operates in this manner, there is no need for a bypass.

-

-

-

OPERATION

-

Turbocharger Sub-assembly

-

At Low Load Range or Low Speed Range

-

When the engine is running in a low load range or a low speed range, the actuator pulls up the actuator linkage. The actuator linkage is connected to the unison ring. At the same time, the drive arms installed in the unison ring move to change the nozzle vane angle toward closing direction. As a result, the exhaust gas travels to the turbine at a faster speed, and engine torque is improved.

-

-

At High Load Range or High Speed Range

-

When the engine is running in a high load range or a high speed range, the actuator pulls down the actuator linkage. With this, the drive arm moves and this opens the nozzle vane and holds the specified supercharging pressure. Thus, exhaust gas back pressure is lowered, and output and fuel consumption are improved.

-

-

-