CLUTCH SYSTEM

-

OUTLINE

-

A dry type single plate clutch operated by hydraulic pressure is used.

-

A Concentric Slave Cylinder (CSC) is used in the clutch hydraulic pressure system.

-

-

SPECIFICATION

Models with 1ZR-FAE Engine Transaxle Type EC60 Clutch Cover Type Diaphragm Spring Size 212 mm (8.35 in.) Installed Load 4500 N Clutch Disc Facing Size

(Outer Diameter x Inner Diameter)

212 mm x 140 mm (8.35 in. x 5.51 in.) Master Cylinder Type Plunger Release Cylinder Type CSC Clutch Pedal With Turnover Clutch Start System Standard Models with 2ZR-FAE Engine Transaxle Type EC60 Clutch Cover Type Diaphragm Spring Size 212 mm (8.35 in.) Installed Load 5100 N Clutch Disc Facing Size

(Outer Diameter x Inner Diameter)

212 mm x 140 mm (8.35 in. x 5.51 in.) Master Cylinder Type Plunger Release Cylinder Type CSC Clutch Pedal With Turnover Clutch Start System Standard Models with 3ZR-FAE Engine Transaxle Type EB60 Clutch Cover Type Diaphragm Spring Size 224 mm (8.82 in.) Installed Load 5500 N Clutch Disc Facing Size

(Outer Diameter x Inner Diameter)

224 mm x 150 mm (8.82 in. x 5.91 in.) Master Cylinder Type Plunger Release Cylinder Type CSC Clutch Pedal With Turnover Clutch Start System Standard -

MAIN FEATURES

-

Concentric Slave Cylinder (CSC)

-

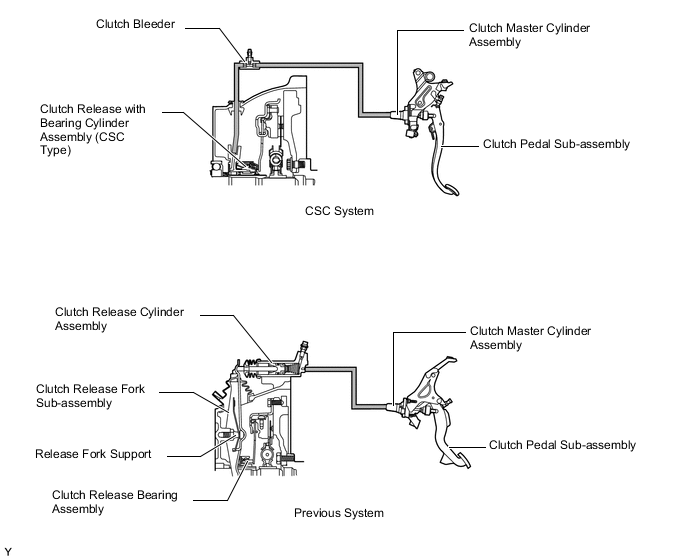

The release cylinder and the release bearing have been combined into one unit. Because of this, the conventional fork and fork support have been discontinued and it is now possible to directly push the bearing with oil pressure, thus achieving excellent clutch operation feeling and weight reduction.

-

A clutch bleeder for air release is provided on the transaxle to ensure serviceability.

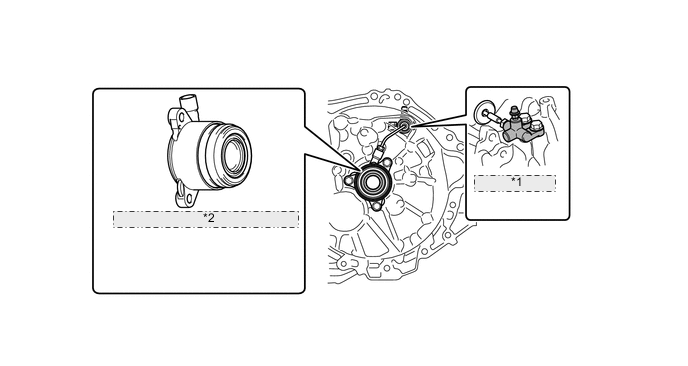

w/ EC60 Manual Transaxle *1 Clutch Bleeder *2 Clutch Release with Bearing Cylinder Assembly (CSC Type)

-

-

-

PRECAUTION

-

The clutch release with bearing cylinder assembly can not be disassembled.

-

When the transaxle is removed from the engine, the piston and piston seal will move to the engine side and the piston seal may be damaged by foreign matter on the sliding surface. When the transaxle is removed from the engine, replace the clutch release with bearing cylinder assembly with a new one.

-

The bolts that fasten the clutch release with bearing cylinder assembly to the transaxle are sealed bolts. When the bolts are removed, replace them with new ones.

-

The clutch fluid should be replaced or inspected according to the Maintenance Schedule and Owner's Manual.

-