ТОПЛИВНАЯ СИСТЕМА ДЕТАЛЬНОЕ ОПИСАНИЕ

-

SYSTEM CONTROL

-

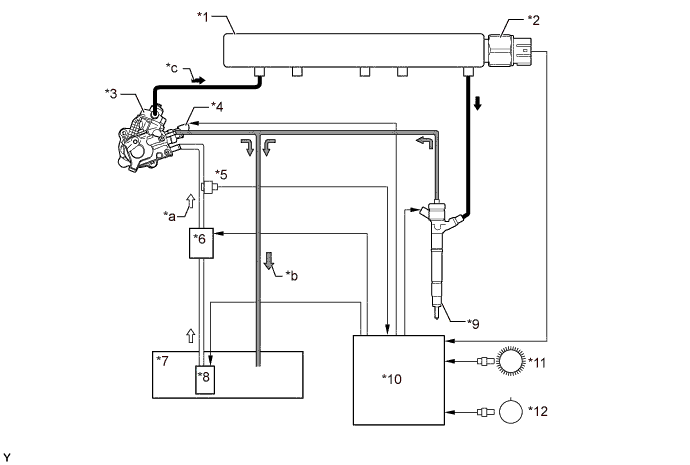

Common-rail System

-

In this system, the highly pressurized fuel supplied by the supply pump assembly is stored in the common-rail assembly, and the ECM sends signals to the injectors in order to control the injection timing and injection volume.

Text in Illustration *1 Common-rail Assembly *2 Fuel Pressure Sensor *3 Supply Pump Assembly *4 Fuel Quantity Control Valve *5 Fuel Temperature Sensor *6 Fuel Filter Assembly

-

Fuel Heater

*7 Fuel Tank Assembly *8 Fuel Suction Tube with Pump and Gauge Assembly

-

Fuel Pump Assembly

*9 Injector Assembly *10 ECM *11 Crankshaft Position Sensor (NE Signal) *12 Camshaft Position Sensor (G Signal) *a Fuel (Low Pressure) *b Fuel (Return) *c Fuel (High Pressure) - - -

-

-

-

CONSTRUCTION

-

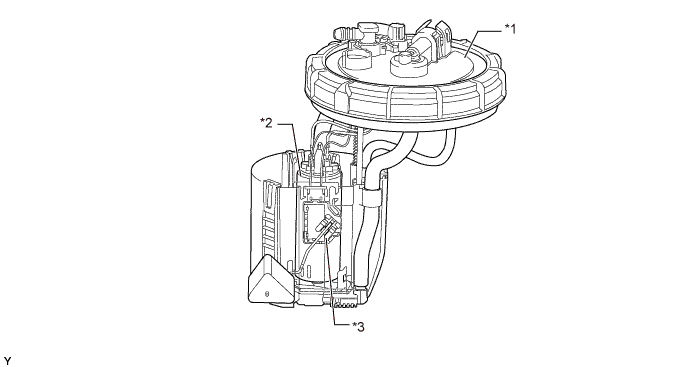

Fuel Suction Tube with Pump and Gauge Assembly

-

A compact fuel suction tube with pump and gauge assembly is used. Its basic components are a fuel pump assembly and a fuel sender gauge assembly.

Text in Illustration *1 Fuel Suction Tube with Pump and Gauge Assembly *2 Fuel Pump Assembly *3 Fuel Sender Gauge Assembly - -

-

-

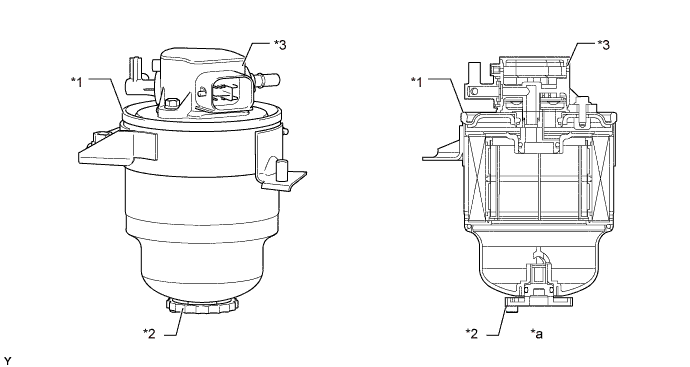

Fuel Filter Assembly

-

A fuel filter assembly with a fuel heater is used.

-

The fuel heater operates according to signals from the ECM.

-

A water level warning switch and a fuel pressure sensor are provided in the auxiliary heater assembly.

-

When the water in the sedimenter section reaches a certain amount, the water level warning switch comes on, the warning light in the combination meter assembly illuminates, and the multi buzzer sounds.

-

The fuel pressure sensor detects the internal fuel pressure of the fuel filter assembly and sends signals to the ECM.

Text in Illustration *1 Fuel Filter Assembly *2 Fuel Sedimenter Drain Plug *3 Auxiliary Heater Assembly

-

Fuel Pressure Sensor

-

Water Level Warning Switch

-

Fuel Heater

- - *a Cross-section - - -

-

-

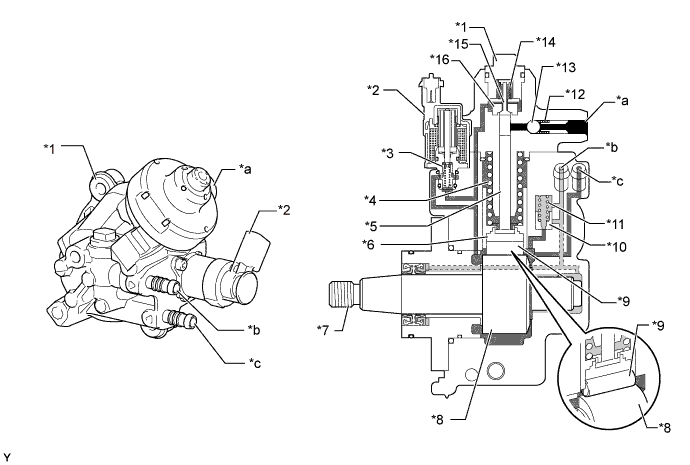

Supply Pump Assembly

-

A CP4 type supply pump assembly is used.

-

The supply pump assembly is driven by the crankshaft via the timing chain. When the crankshaft rotates one revolution, the camshaft of the supply pump assembly also rotates one revolution.

-

The supply pump assembly consists of a camshaft, a roller, a plunger, a check valve, a check ball, a fuel over flow valve and a fuel quantity control valve.

-

A double cam is used so that fuel injection can be carried out simultaneously with fuel pumping to the common-rail assembly.

-

The supply pump assembly is lubricated with fuel.

Text in Illustration *1 Supply Pump Assembly *2 Fuel Quantity Control Valve *3 Flow Control Valve *4 Tappet Spring *5 Plunger *6 Tappet *7 Camshaft *8 Double Cam *9 Roller *10 Fuel Over Flow Valve *11 Fuel Over Flow Valve Spring *12 Check Ball Spring *13 Check Ball *14 Check Valve Spring *15 Check Valve *16 Valve Plate *a To Common-rail Assembly *b Fuel Return Port (to Fuel Tank Assembly) *c Fuel Inlet Port (from Fuel Pump Assembly) - - Tech Tips

When installing the supply pump assembly, it is necessary to match the sprocket position of the crankshaft and the sprocket position of the supply pump assembly. For details of the installation of the supply pump assembly, refer to the Repair Manual.

-

-

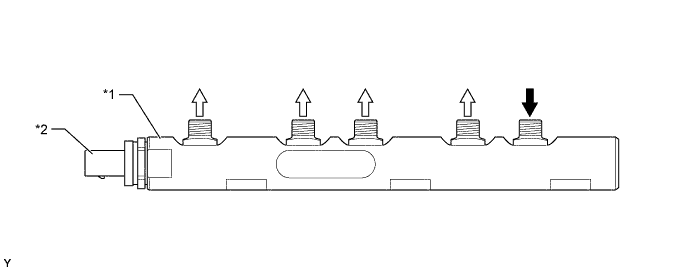

Common-rail Assembly

-

A common-rail assembly made of case hardened steel is used.

-

The function of the common-rail assembly is to store the fuel that has been pressurized by the supply pump assembly.

-

The common-rail assembly is provided with a fuel pressure sensor.

-

The fuel pressure sensor detects the fuel pressure in the common-rail assembly.

Text in Illustration *1 Common-rail Assembly *2 Fuel Pressure Sensor

From Supply Pump Assembly

To Injector Assembly

-

-

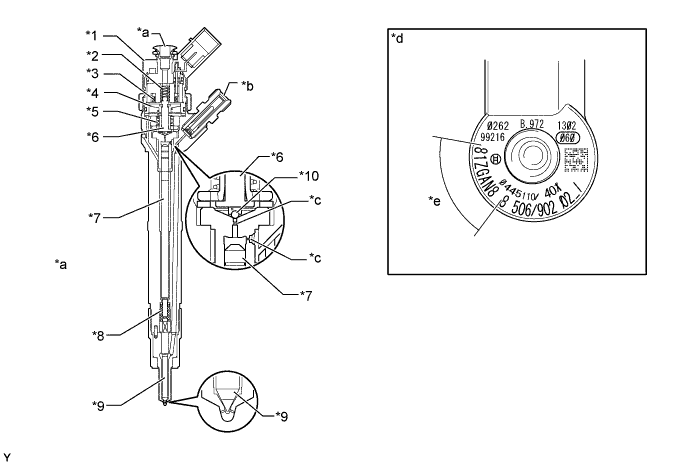

Injector Assembly

-

Solenoid valve type injector assemblies are used.

-

Each injector assembly consists of a nozzle needle, a piston, and a solenoid valve.

-

An injector compensation value (code) containing encoded characteristics of the injector is printed on each injector.

Text in Illustration *1 Injector Assembly *2 Solenoid Valve Spring *3 Solenoid Coil *4 Armature *5 Armature Spring *6 Solenoid Valve *7 Piston *8 Nozzle Needle Spring *9 Nozzle Needle *10 Check Ball *a Fuel (Return) *b Fuel (from Common-rail Assembly) *c Orifice *d View from Top Side *e Compensation Value - - Tech Tips

-

Differences in the injection volume occur when the injector assembly is manufactured. The injection volume is measured after manufacturing. Based on the measured value, a compensation value (code) is assigned to each injector assembly. The compensation value (code) for each cylinder is stored in the ECM. The ECM corrects the injection volume based on the code.

-

When replacing an injector assembly, check that the code stored in the ECM and the code of the injector assembly match for each cylinder. For details of injector assembly replacement, refer to the Repair Manual.

-

-

-

-

OPERATION

-

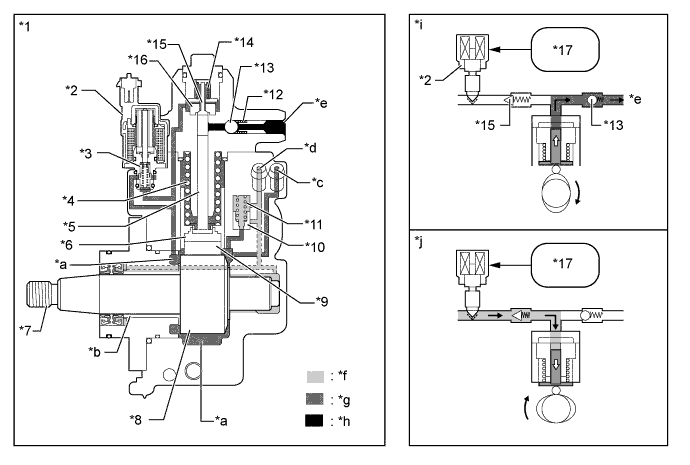

Supply Pump Assembly

-

The fuel fed from the fuel pump assembly flows to the camshaft space. The fuel lubricates the supply pump assembly through the bearing bush and returns to the fuel tank. In addition, excess fuel returns from the fuel over flow valve to the fuel tank.

-

The fuel in the camshaft space flows to the flow control valve in the fuel quantity control valve. The flow rate of the fuel which passes through the flow control valve is controlled and the fuel flows to the valve plate.

-

When the camshaft rotates and the plunger is pushed down due to the force of the tappet spring, the check valve is pushed down due to the fuel applied against the check valve spring or pulled down due to the downward movement of the plunger. As a result, the fuel can flow into the cylinder.

-

When the camshaft rotates further and the cam pushes up the plunger via the roller and tappet, the check valve closes and the fuel pressure in the cylinder increases. When the force of the fuel pressure in the cylinder becomes higher than the combined force of the fuel pressure of the common-rail assembly and the force of the check ball spring in the supply pump assembly, the fuel pushes open the check ball and flows to the common-rail assembly.

-

The ECM controls the opening of the flow control valve in the fuel quantity control valve in order to regulate the volume of fuel that is pumped by the supply pump assembly to the common-rail assembly. Consequently, the fuel pressure in the common-rail assembly is controlled to the target injection pressure.

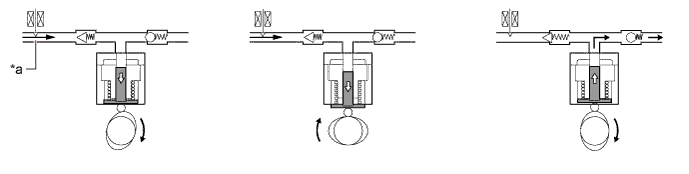

Text in Illustration *1 Supply Pump Assembly *2 Fuel Quantity Control Valve *3 Flow Control Valve *4 Tappet Spring *5 Plunger *6 Tappet *7 Camshaft *8 Double Cam *9 Roller *10 Fuel Over Flow Valve *11 Fuel Over Flow Valve Spring *12 Check Ball Spring *13 Check Ball *14 Check Valve Spring *15 Check Valve *16 Valve Plate *17 ECM - - *a Camshaft Space *b Bearing Bush *c Fuel Inlet Port (from Fuel Pump Assembly) *d Fuel Return Port (to Fuel Tank Assembly) *e To Common-rail Assembly *f Return Fuel *g Fuel Feed *h High Pressure Fuel *i Plunger Moved from BDC to TDC *j Plunger Moved from TDC to BDC -

When the opening of the flow control valve in the fuel quantity control valve is small, the fuel flow area is kept small, which decreases the transferable fuel quantity.

-

Even when the plunger strokes fully, the flow volume continues to be small due to the small flow area.

-

Pumping will start when the fuel pressure has become higher than the total power of the common-rail assembly pressure and the check ball spring force.

Text in Illustration *a Small Flow Area - - -

When the opening of the flow control valve in the fuel quantity control valve is large, the fuel flow area is kept large, which increases the transferable fuel quantity.

-

If the plunger strokes fully, the flow volume will increase because the flow area is large.

-

Pumping will start when the fuel pressure has become higher than the total power of the common-rail assembly pressure and the check ball spring force.

Text in Illustration *a Large Flow Area - -

-

-

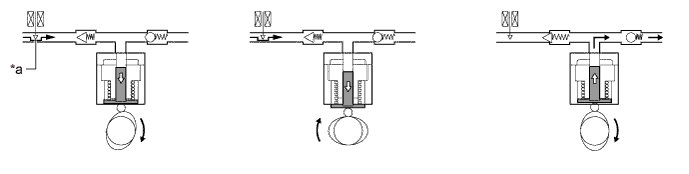

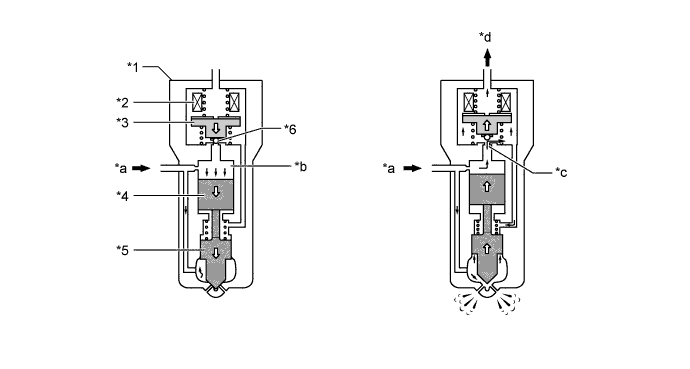

Injector Assembly

-

When electrical current is applied to the solenoid coil, it pulls the solenoid valve up.

-

The orifice of the control chamber opens, allowing the fuel to flow out.

-

The fuel pressure in the control chamber decreases.

-

Simultaneously, fuel flows from the orifice to the bottom of the piston and raises the piston up (to enhance response).

-

As a result, the piston raises the nozzle needle to inject fuel.

-

When the electrical current applied to the solenoid coil is stopped, the solenoid valve is pushed down and the orifice of the control chamber is closed.

-

The fuel pressure in the control chamber increases.

-

As a result, the piston and the nozzle needle are pushed down and fuel injection stops.

Text in Illustration *1 Injector Assembly *2 Solenoid Coil *3 Solenoid Valve *4 Piston *5 Nozzle Needle *6 Check Ball *a Fuel (from Common-rail Assembly) *b Control Chamber *c Orifice *d Fuel (Return)

-

-