LUBRICATION SYSTEM DETAILS

-

CONSTRUCTION

-

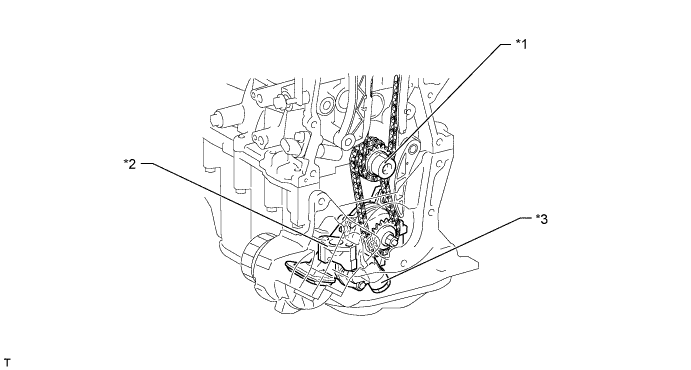

Oil Pump Assembly

-

The trochoidal type oil pump assembly is driven by the crankshaft, and fits compactly inside the oil pan.

-

A relief valve has been provided on the oil pump assembly, thus, any excessive pressure rises are restrained and friction loss is reduced.

Text in Illustration *1 Crankshaft *2 Oil Pump Assembly *3 Relief Valve - -

-

-

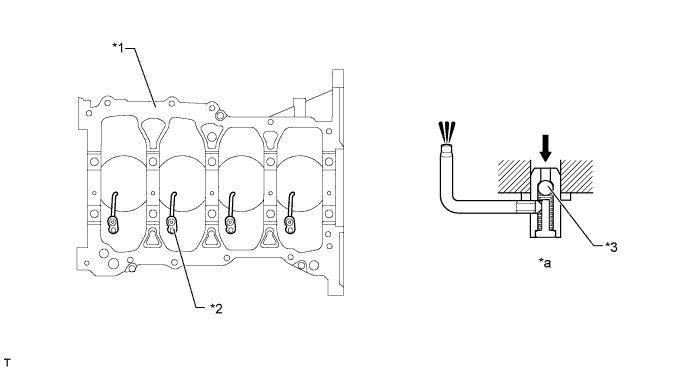

No. 1 Oil Nozzle Sub-assembly

-

No. 1 oil nozzle sub-assemblies for cooling and lubricating the pistons are provided in the cylinder block sub-assembly.

-

These No. 1 oil nozzle sub-assemblies contain a check ball to prevent oil from being fed when the oil pressure is low. This prevents the overall oil pressure in the engine from dropping.

Text in Illustration *1 Cylinder Block Sub-assembly *2 No. 1 Oil Nozzle Sub-assembly *3 Check Ball - - *a No. 1 Oil Nozzle Sub-assembly Cross Section - -

Oil - -

-

-

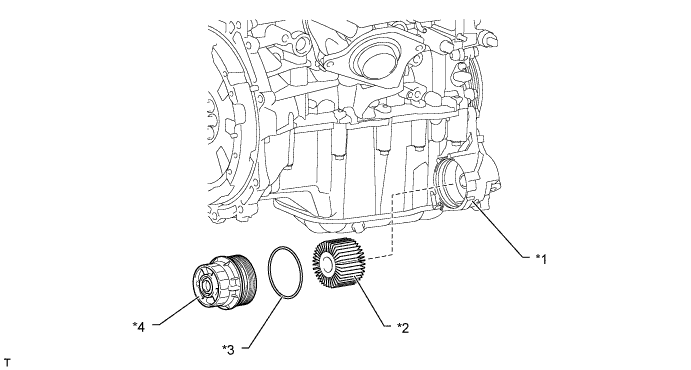

Oil Filter Element

-

A replaceable oil filter element is used. The oil filter element uses a high-performance filter paper to improve filtration performance. It is also combustible for environmental protection.

Text in Illustration *1 Oil Filter Bracket Sub-assembly *2 Oil Filter Element *3 O-ring *4 Oil Filter Cap Assembly Tech Tips

The engine oil maintenance interval for a model that has an oil filter with a replaceable oil filter element is the same as that for a conventional model.

-

-