POWER STEERING SYSTEM DETAILS

-

FUNCTION OF MAIN COMPONENTS

-

The main components of the EPS system are as follows:

Component Function Steering Column Assembly Torque Sensor Detects the twist of the torsion bar, calculates the torque that is applied to the torsion bar by changing it into an electrical signal, and outputs this signal to the power steering ECU. Rotation Angle Sensor Outputs the rotation angle of the motor to the power steering ECU. Power Steering Motor Generates assist torque in accordance with a signal received from the power steering ECU. Reduction Mechanism Reduces the speed of the power steering motor through the use of a worm gear and a wheel gear and transmits it to the column shaft. Power Steering ECU Actuates the power steering motor mounted on the steering column assembly to provide assist torque, based on the signals received from various sensors and ECUs. Parking Assist ECU* Transmits the intelligent parking assist system control signal to the power steering ECU. Skid Control ECU

-

Transmits the vehicle speed signal to the power steering ECU.

-

Requests steering torque assist during steering cooperative control.

Air Conditioning Amplifier Assembly Receives a signal from the power steering ECU to limit the electrical usage. Combination Meter P/S Warning Light Illuminates to alert the driver when the power steering ECU detects a malfunction in the EPS system.

-

*: Models with intelligent parking assist system

-

-

-

SYSTEM CONTROL

-

The EPS system has the following controls:

Control Outline Basic Control Calculates the assist current from the steering torque value and the vehicle speed, and actuates the power steering motor. Inertia Compensation Control Ensures the starting movement of the power steering motor when the driver starts to turn the steering wheel. Recovery Control During the short interval between the times the driver fully turns the steering wheel and the wheels try to recover, this control assists the recovery force. Damper Control Regulates the amount of assist when the driver turns the steering wheel while driving at high speeds, thus damping the changes in the yaw rate of the vehicle body. Voltage Boost Control* Boosts the auxiliary battery voltage in the power steering ECU. It maintains 0 volts when the driver does not turn the steering wheel or the vehicle is being driven straight. It effects variable control between 27 to 34 volts in accordance with the load, when the driver is turning the steering wheel. System Overheat Protection Control Estimates the power steering motor temperature based on the amperage and the current duration. If the temperature exceeds the standard, it limits the amperage to prevent the power steering motor from overheating. Electric Load Control Prevents decreasing the assist torque when the auxiliary battery voltage is decreased. Cooperative Control (VSC+) The EPS system performs control in cooperation with the brake control system. Cooperative Control (Intelligent Parking Assist System)* The EPS system performs control in cooperation with the intelligent parking assist system.

-

*: Models with intelligent parking assist system

-

-

Electric Load Control

-

When the power steering ECU detects the auxiliary battery voltage decrease, it transmits the electric load control signal to the air conditioning amplifier in order to limit the electrical usage.

-

The air conditioning amplifier limits operation of rear window defogger and PTC heater until the power steering ECU releases the limitation demand.

-

-

Cooperative Control with VSC+

-

The power steering ECU effects cooperative control with the skid control ECU, in order to control the steering assist torque in accordance with information received from the skid control ECU. This facilitates the steering operation of the driver, thus realizing a high level of vehicle stability. For details, refer to the Brake Control System section.

-

-

Cooperative Control with Intelligent Parking Assist System

-

When the vehicle is parked in a garage or in parallel, the intelligent parking assist system assists steering in accordance with the signal from the parking assist ECU. For details, refer to the Intelligent Parking Assist System section.

-

-

-

CONSTRUCTION

-

Steering Column Assembly

-

The steering column assembly includes a torque sensor, power steering motor and reduction mechanism.

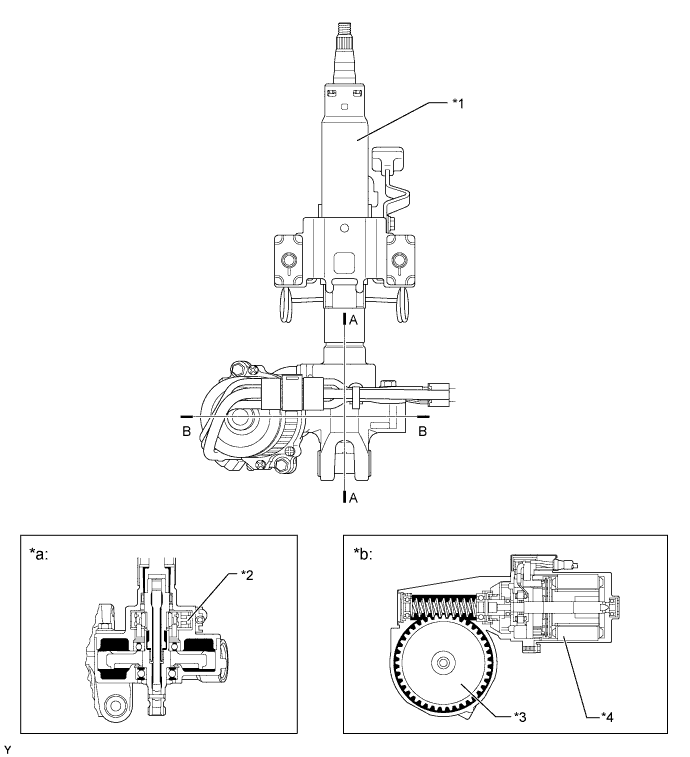

Text in Illustration *1 Steering Column Assembly *2 Torque Sensor *3 Reduction Mechanism *4 Power Steering Motor *a A-A Cross Section *b B-B Cross Section -

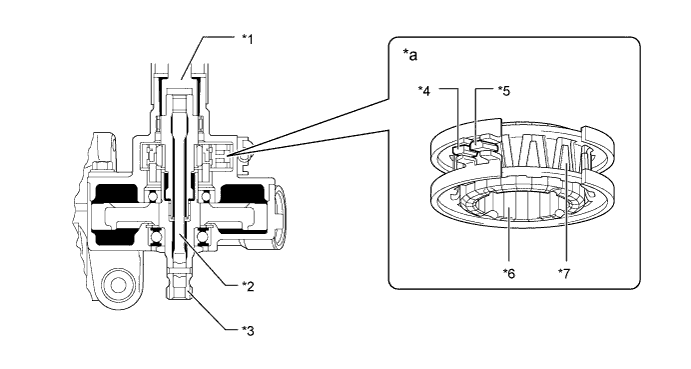

The power steering torque sensor is built into the steering column assembly. A multipole magnet is mounted to the input shaft, and a yoke is mounted to the output shaft. The input and output shafts are joined by a torsion bar.

-

The power steering torque sensor contains 2 Hall ICs which face opposite to each other. The system detects the steering direction in accordance with the direction of the magnetic flux that passes between the Hall ICs. Furthermore, the system detects steering torque in accordance with the amount of change in the magnetic flux density based on the relative displacement of the multipole magnet and the yoke. The power steering ECU monitors the torque sensor signals output by the 2 Hall ICs to detect malfunctions.

Text in Illustration *1 Input Shaft *2 Torsion Bar *3 Output Shaft *4 Hall IC 2 *5 Hall IC 1 *6 Multipole Magnet *7 Yoke - - *a Power Steering Torque Sensor - - -

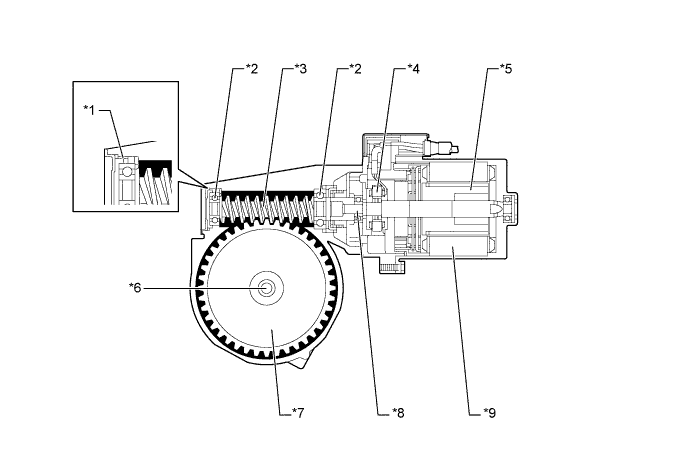

A low inertia, low noise, and high power output brushless type power steering motor is used.

-

The power steering motor consists of a rotor, stator, motor shaft and rotation angle sensor.

-

The rotation angle sensor consists of a highly reliable and durable resolver sensor. The rotation angle sensor detects the rotation angle of the motor and outputs it to the power steering ECU. As a result, it ensures efficient EPS control.

-

The torque that is generated by the power steering motor is transmitted via the joint to the reduction mechanism.

-

The reduction mechanism reduces the speed of the power steering motor via the worm gear and the wheel gear, and transmits it to the column shaft.

-

The wheel gear is made of a high strength, low friction, and low wear plastic material, to realize low noise and a lightweight construction.

-

A worm gear supported by ball bearings is used. Also, a leaf spring is provided to ensure optimal gear engagement at all times.

Text in Illustration *1 Leaf Spring *2 Ball Bearing *3 Worm Gear *4 Rotation Angle Sensor *5 Rotor *6 Column Shaft *7 Wheel Gear *8 Motor Shaft *9 Stator - -

-

-

-

OPERATION

-

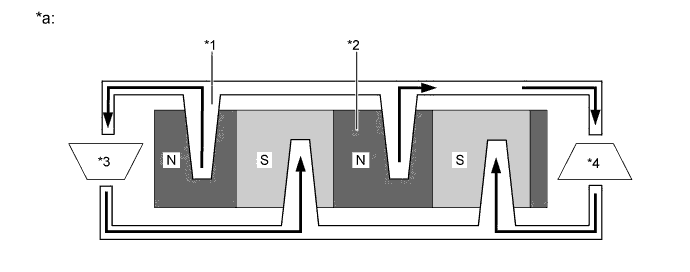

When the steering wheel is not turned

-

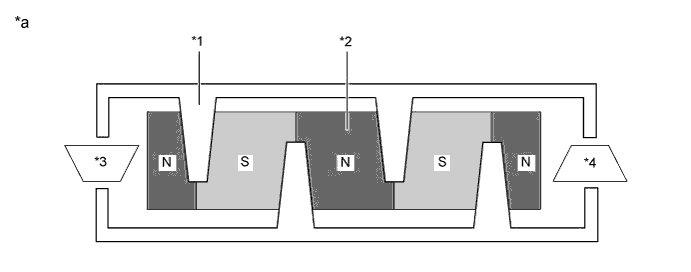

If the vehicle is driven straight and the driver does not turn the steering wheel, the yoke is centered between the N and S poles of the multipole magnet. Thus, no magnetic flux passes between the Hall ICs. In this case, the Hall ICs output a specified voltage to the power steering ECU, to indicate that the steering wheel is in the neutral position. Therefore, current is not applied to the motor

Text in Illustration *1 Yoke Tab *2 Multipole Magnet *3 Hall IC 2 *4 Hall IC 1 *a Simplified Diagram of Torque Sensor - -

-

-

When the steering wheel is turned right or left

-

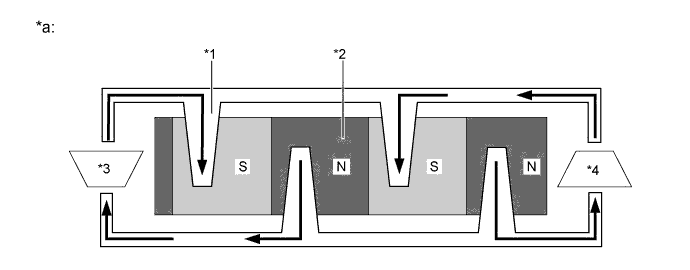

When a driver turns the steering wheel to the right or left, the twist created in the torsion bar creates a relative displacement between the multipole magnet and yoke.

-

At this time, the magnetic flux from the N to S poles of the multipole magnet passes between the Hall ICs. The system detects the direction the steering wheel is being turned in accordance with the direction of the magnetic flux that passes between the Hall ICs. Hall IC1 and Hall IC2 are installed facing opposite to each other. As a result, the output characteristics of the 2 Hall ICs are constantly opposite each other. The system monitors the different outputs of these Hall ICs in order to detect malfunctions.

-

The magnetic flux density becomes higher as the Hall ICs get closer to the center of each respective pole. Each Hall IC converts these magnetic flux fluctuations into voltage fluctuations in order to transmit the rotational torque of the steering wheel to the power steering ECU.

Text in Illustration *1 Yoke Tab *2 Multipole Magnet *3 Hall IC 2 *4 Hall IC 1 *a Simplified diagram of torque sensor - -

Text in Illustration *1 Yoke Tab *2 Multipole Magnet *3 Hall IC 2 *4 Hall IC 1 *a Simplified diagram of torque sensor - -

-

-

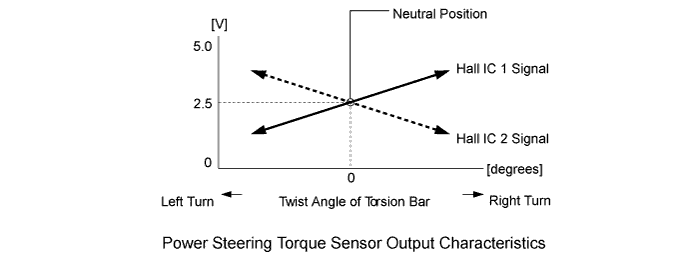

Power Steering Torque Sensor Output Characteristics

-

When the driver does not turn the steering wheel, the power steering torque sensor outputs a specified voltage (2.5 V) to the power steering ECU. As long as the specified voltage is output, the power steering ECU determines that the steering wheel is in the neutral position.

-

When the driver turns the steering wheel to the right or left, the voltage output from the power steering torque sensor to the power steering ECU changes. Based on the changes, the power steering ECU determines the steering torque and steering direction input by the driver.

-

-

-

FAIL-SAFE

-

If the power steering ECU detects a malfunction in the EPS system, the power steering ECU illuminates the P/S warning light to inform the driver.

-

At the same time, the power steering ECU changes the control according to detected malfunctions to limit the assist force or disable the assist, thus ensuring the steering maneuverability. For details, refer to the Repair Manual.

Tech Tips

The power steering ECU also limits the assist force or turns on the P/S warning light if the battery voltage temporarily decreases

-

-

DIAGNOSIS

-

When the power steering ECU detects a malfunction in the EPS system, the power steering ECU makes a diagnosis and memorizes the failed section. At the same time, the Diagnostic Trouble Code (DTC) is stored in the power steering ECU memory.

-

The DTC can be read by connecting an intelligent tester to the DLC3, or by connecting the SST (09843-18040) to the TC and CG terminals of the DLC3 and observing the blinks of the P/S warning light. For details, refer to the Repair Manual.

-