FUEL SYSTEM DETAILS

-

SYSTEM CONTROL

-

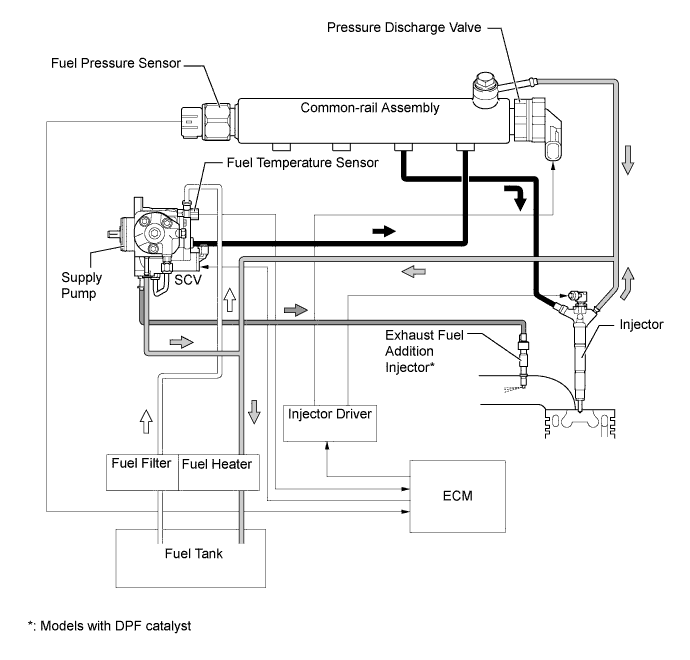

Common-rail System

-

In this system, the highly pressurized fuel supplied by the supply pump is stored in the common-rail assembly, and the ECM sends signals to the injectors by way of the injector driver in order to control the injection timing and injection volume.

-

-

-

CONSTRUCTION

-

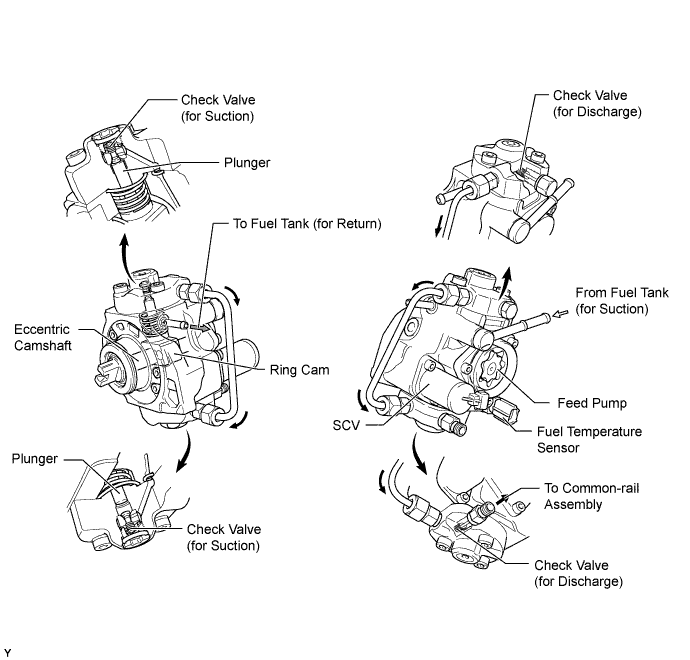

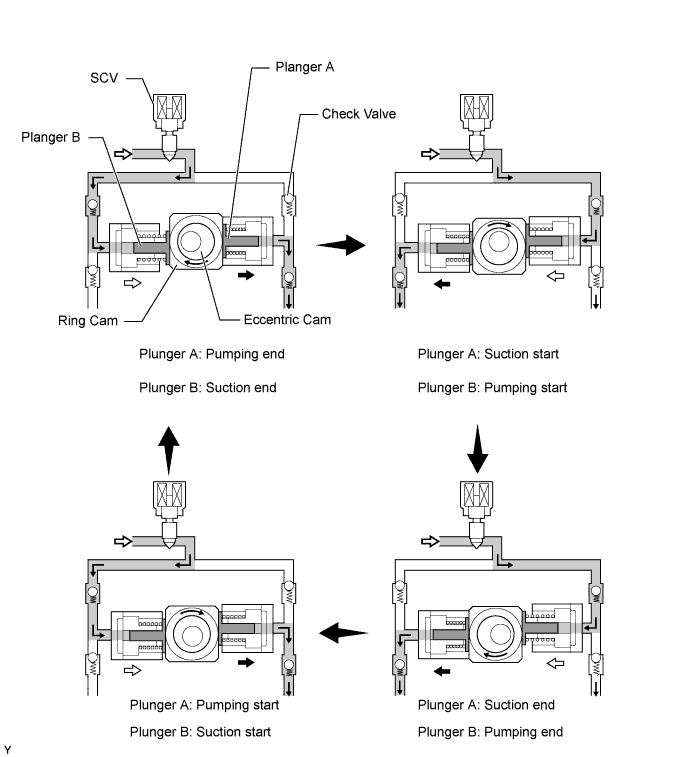

Supply Pump

-

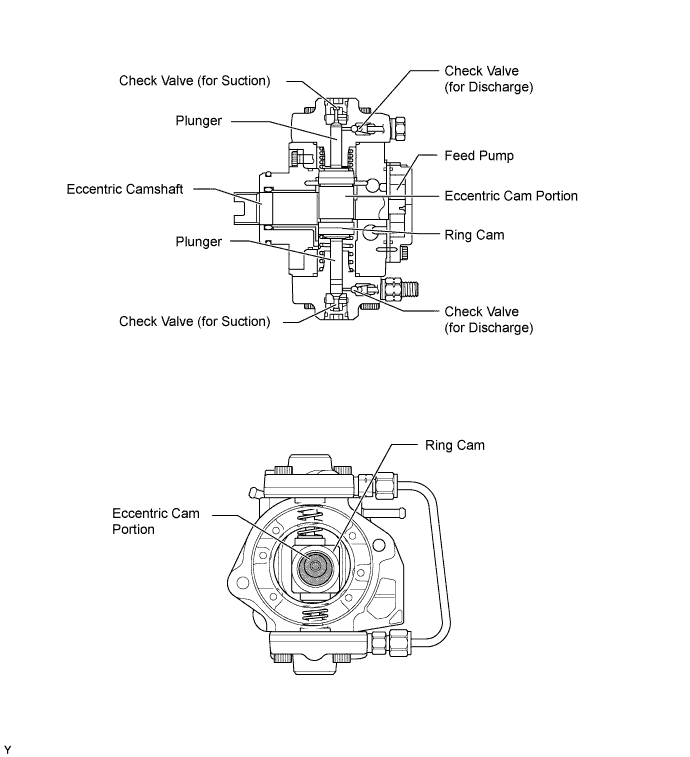

The supply pump consists of an eccentric camshaft, a ring cam, 2 plungers, 4 check valves, a Suction Control Valve (SCV), a fuel temperature sensor, and a feed pump.

-

The 2 plungers are placed opposite each other outside of the ring cam.

-

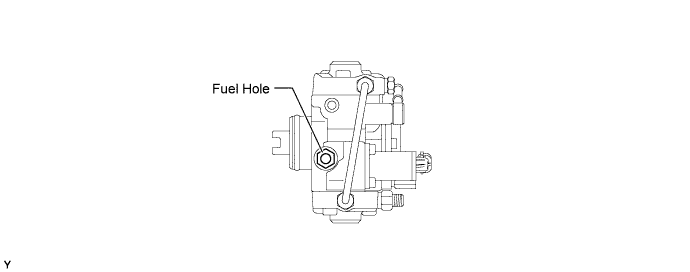

On models with the DPF catalyst, a fuel outlet for the exhaust fuel addition injector has been added.

-

-

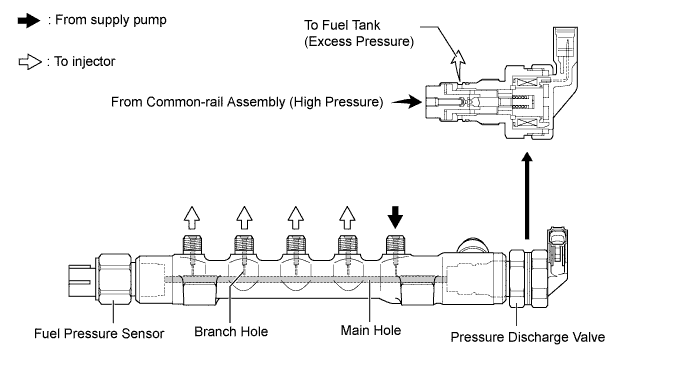

Common-rail Assembly

-

The function of the common-rail assembly is to store the fuel that has been pressurized by the supply pump. The common-rail assembly is provided with a fuel pressure sensor that detects the fuel pressure in the common-rail, and a pressure discharge valve, which regulates the fuel pressure.

-

Internally, the common-rail assembly contains a main hole and 5 branch holes that intersect the main hole. Each branch hole functions as an orifice that dampens the fluctuation of the fuel pressure.

-

In the pressure discharge valve, the plunger opens and closes in accordance with the actuation signals from the injector driver. Thus, it regulates pressure by releasing excess pressure from the common-rail assembly. In addition, it has a pressure reduction function in case of emergency.

Tech Tips

Because the fuel pressure sensor use a plastic-deformed sealing portion to ensure sealing performance, it cannot be reused after disassembling. The fuel pressure sensor and pressure discharge valve are supplied as a set with the common-rail assembly. Do not disassemble the fuel pressure sensor and pressure discharge valve. Also, if parts that affect the alignment have been changed, make sure to replace the pipe with a new one as well. The parts that require the replacement of a pipe are listed below:

-

Injection pipe: injector, common-rail, cylinder head and intake manifold

-

Fuel inlet pipe: supply pump, common-rail, cylinder head and intake manifold

For details, refer to the AVENSIS Repair Manual.

-

-

-

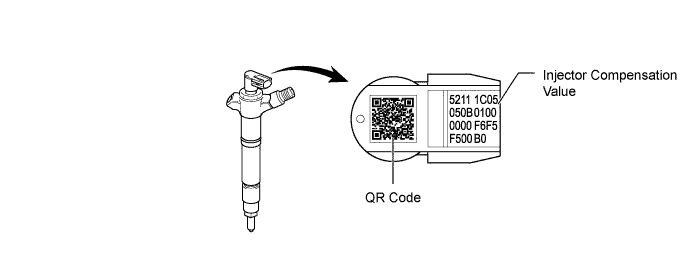

Injector

-

A piezo type fuel injector is used to optimize fuel injection volume and reduce exhaust emissions.

-

An injector compensation value and QR code containing encoded characteristics of the injector are printed on each injector.

-

The injector compensation value and QR code contain various pieces of information regarding the injector, such as model code and injection volume correction.

Tech Tips

-

If the ECM is replaced, use the intelligent tester II and input the injector compensation values of all 4 injectors. If one of the injectors is replaced, input the injector compensation value of the replaced injector. For details, refer to the AVENSIS Repair Manual.

-

The QR code, which requires a special scan tool, is not used at Toyota dealers.

-

What is QR Code?

-

QR code, a matrix symbology consisting of an array of nominally square cells, allows omni-directional, high-speed reading of large amounts of data.

-

QR code encodes many types of date such as numeric, alphanumeric, kanji, kana and binary code. A maximum of 7089 characters (numeric) can be encoded.

-

QR code (2D code) contains information in the vertical and horizontal directions, whereas a bar code contains data in one direction only. QR code (2D code) holds a considerably greater volume of information than a bar code.

-

-

-

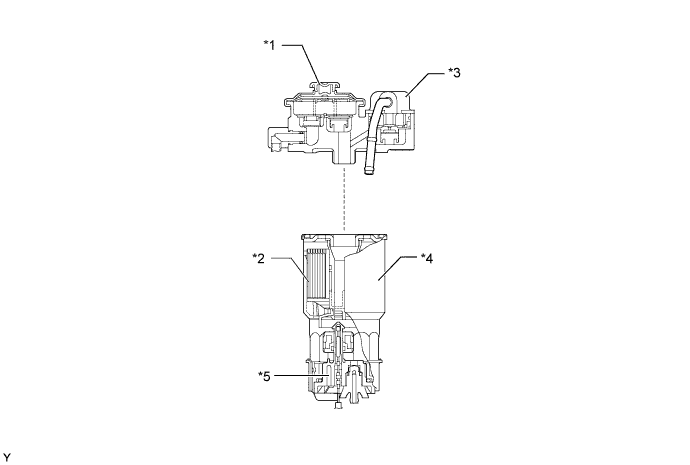

Fuel Filter

-

The fuel filter consists of a fuel filter element integrated with the fuel filter housing.

-

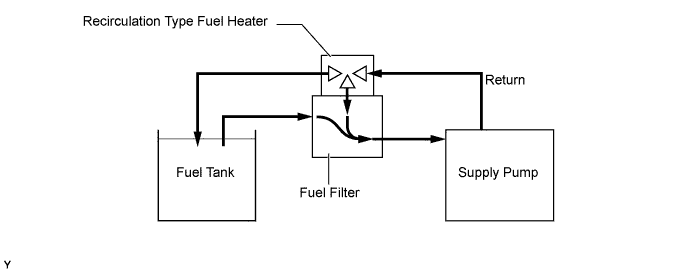

A recirculation type fuel heater is used.

Text in Illustration *1 Priming Pump *2 Filter Element *3 Fuel Heater *4 Fuel Filter *5 Fuel Sedimenter Level Warning Switch - -

-

-

-

OPERATION

-

Supply Pump

-

Due to the rotation of the eccentric cam, the ring cam pushes plunger A upward as illustrated below. The force of the spring pulls plunger B (which is located opposite plunger A) upward. As a result, plunger B draws fuel in, and plunger A pumps fuel at the same time.

-

-

Fuel Filter

-

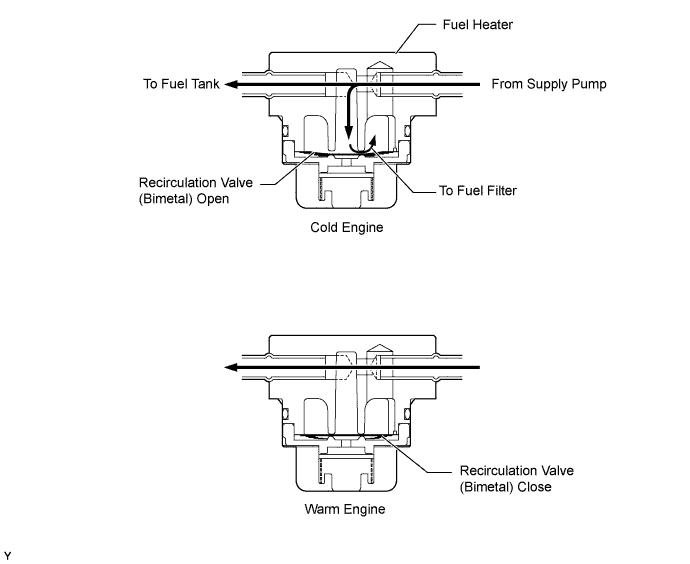

A recirculation type fuel heater is used. This heater heats the fuel by recirculating the returned fuel, which is given a high temperature by the fuel pumping of the supply pump, to the fuel filter.

-

While the engine is cold, the recirculation valve inside the fuel heater will open due to the bimetal action, so the return fuel will return to the fuel filter and the fuel tank.

-

While the engine is warm, the recirculation valve will close due to the bimetal action, so all the return fuel will return to the fuel tank.

-

When the water in the sedimenter section reaches a certain amount, the fuel sedimenter level warning switch comes on, and the warning light in the combination meter illuminates.

-

-