QUARTER PANEL CUT AND JOIN REPLACEMENT SECTIONS

- Quarter Panel Replacement Using Adhesive

-

Cut the wheel arch portion.

-

Heat the quarter panel adhesive area and remove the quarter panel.

Tech Tips

Using an industrial heater gun or gas burner, heat the quarter panel to 110 to 140°C. Make sure the quarter panel does not warp.

-

Clean off any adhesive that remains on the vehicle.

Tech Tips

-

Using an industrial heater gun or gas burner, heat the adhesive to 110 to 140°C.

-

Using a scraper, scrape away the adhesive.

-

If adhesive remains, the strength of any subsequently applied adhesive will be weak.

-

-

Using a disc grinder or belt sander, scuff and sand any adhesive that remains on the vehicle.

Tech Tips

Scuff at a width of approximately 10 mm (0.39 in.) over the previous adhesive coating.

-

Apply adhesive to the exposed metal areas on the vehicle. Using a spatula, spread the adhesive evenly.

-

Apply adhesive to the vehicle again.

-

Using #60-120 grit sandpaper, scuff the adhesive application area on the new quarter panel.

-

Apply adhesive to the new quarter panel. Using a spatula, spread the adhesive evenly.

-

Using a vise grip or the palms of your hands, press the quarter panel so that the thickness of the adhesive is even.

-

Complete installation the new quarter panel.

-

Dry the adhesive areas of the new quarter panel.

Tech Tips

-

With dryer or equivalent (60°C): 60 minutes (complete hardening: 90 minutes)

-

Ambient temperature (25°C): 12 hours (complete hardening: 24 hours)

-

Work Procedure

-

REMOVAL

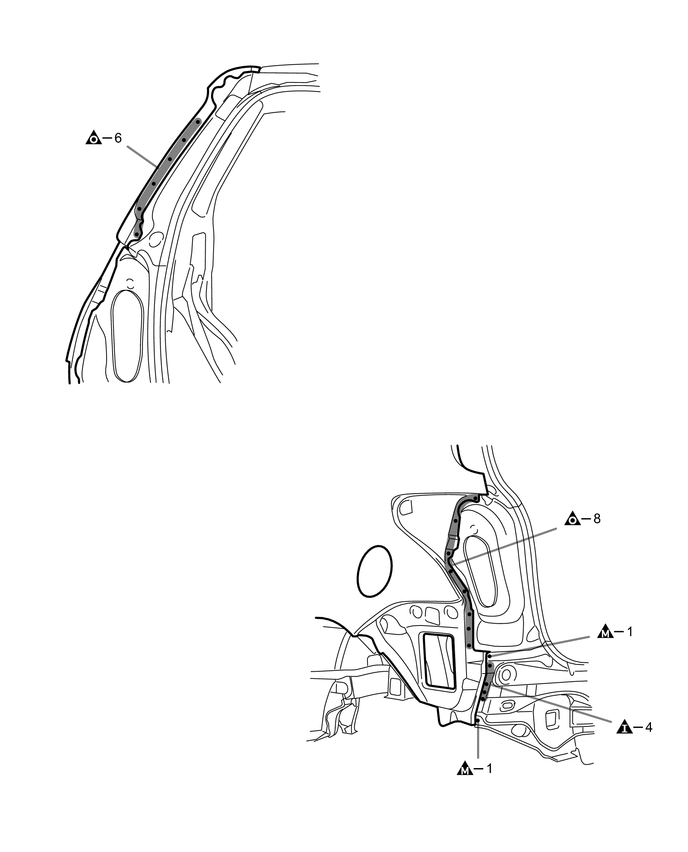

Symbol Meaning

Remove Weld Points

Remove Weld Points

Remove Weld Points

Cut and Join Location

Cut Location for Supply Parts

-

*a in illustration above indicates where the adhesive is located.

-

Roughly cut open the panel so that the adhesive can be reached. Cut through the adhesive with a cut chisel to remove the panel.

Tech Tips

In cases where the adhesive cannot be removed with a cut chisel, heat the adhesive with an industrial heater gun or gas burner taking care not to cause panel deformation by overheating.

REMOVAL POINT

*b mm (in.) - -

-

-

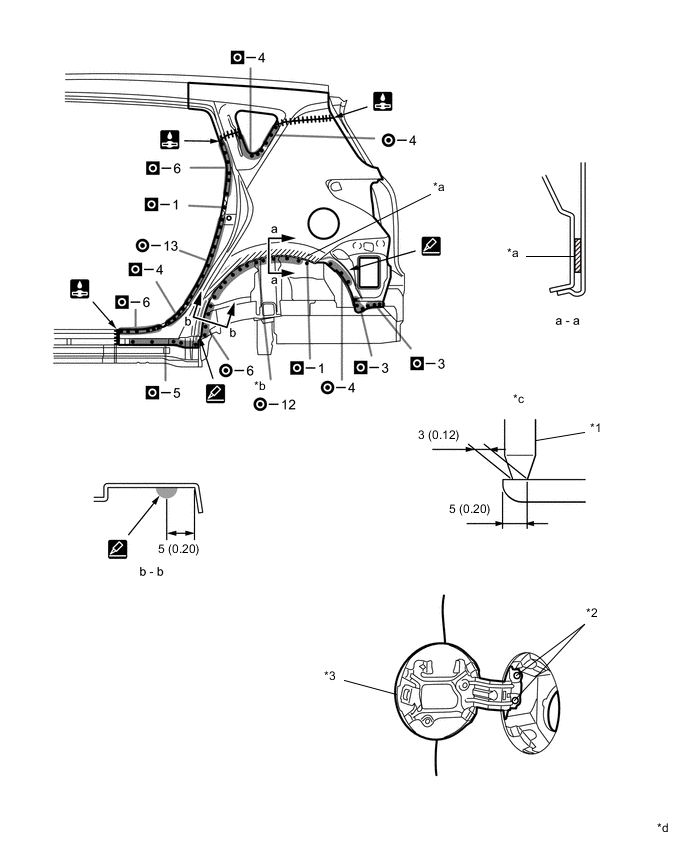

INSTALLATION

Symbol Meaning

Spot Weld

Plug Weld

Plug Weld

Plug Weld

Butt Weld

Body Sealer

-

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the finish.

-

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension diagram. (See the body dimensions)

-

Before installing a new part, apply body sealer.

Tech Tips

-

Apply body sealer evenly about 5 mm (0.20 in.) from the flange, avoiding any oozing.

-

Apply body sealer evenly, about 3 to 4 mm (0.12 to 0.16 in.) in diameter.

-

-

Apply adhesive (3MTMAutomixTMPanel Bonding Adhesive #8115) to the area indicated by *a in the illustration.

Tech Tips

Apply enough adhesive for the panels to stick to each other.

-

Areas indicated by *b in the illustration, combine welding with adhesive. (difficult to get stable strength by one way) If use the spot welder, modify the spot tip as shown in the illustration *c so that it can fit in the narrow flange.

-

After welding, apply foamed sealing material to the corresponding parts. (See the painting / coating)

-

After welding, apply body sealer to the corresponding parts. (See the painting / coating)

-

After applying the top coat, apply anti-rust agent to the internal panel portion of the closed section structural weld points.

INSTALLATION POINT

*1 Spot Tip *2 Rivets *3 Fuel Filler Opening Lid - - *d mm (in.) - -

-