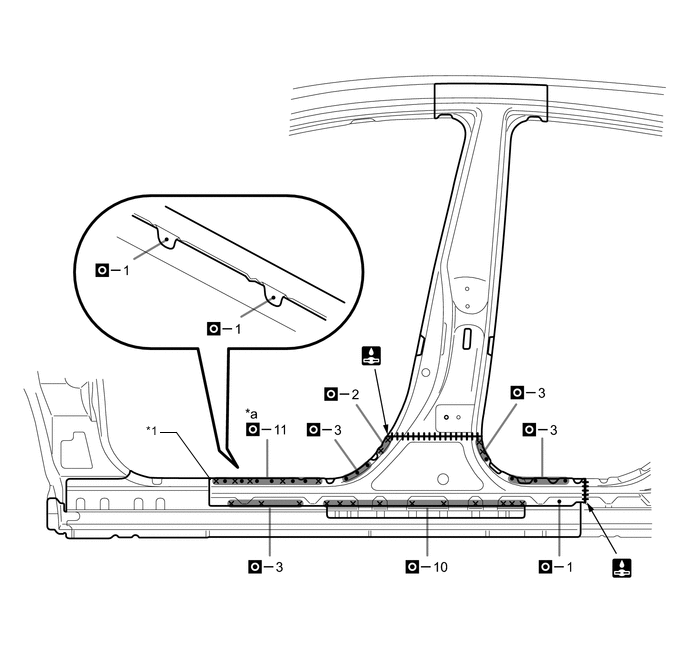

ROCKER PANEL CUT AND JOIN REPLACEMENT SECTIONS

-

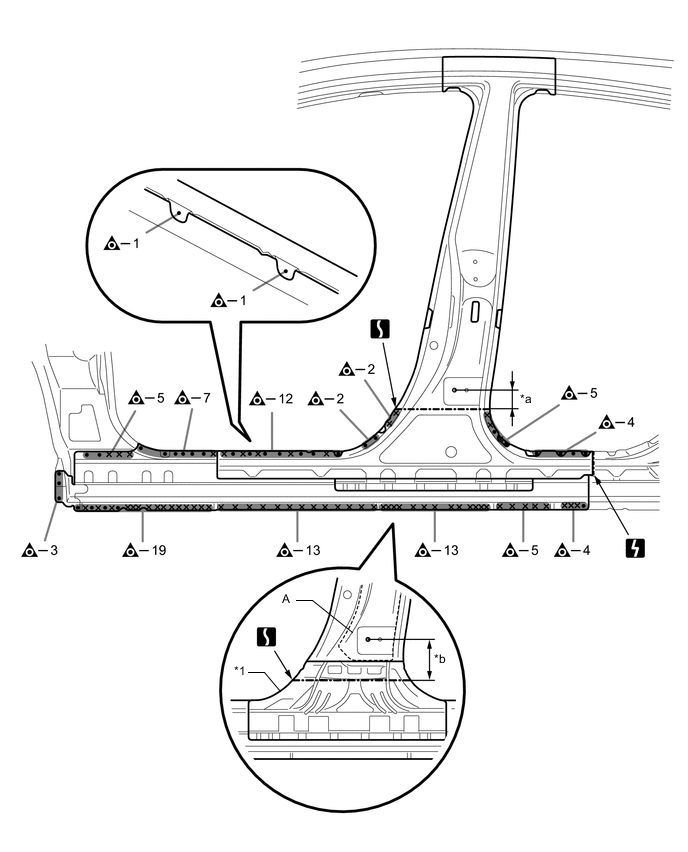

With the front body pillar cut and join replacement sections (pattern 1) removed.

-

REMOVAL

Symbol Meaning

Remove Weld Points

Remove Weld Points

Cut and Join Location

Cut Location for Supply Parts

-

Do not butt weld or heat repair because the heat decreases the strength of areas where ultra high strength steel is used. (See the introduction)

-

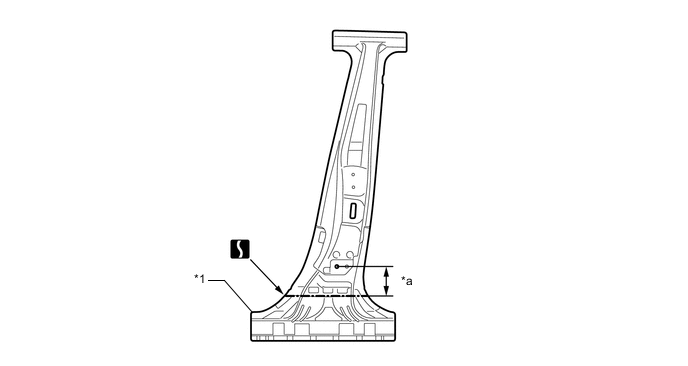

Carefully cut the center body pillar reinforcement sub-assembly so not to damage A.

*1 CENTER BODY PILLAR REINFORCEMENT SUB-ASSEMBLY - - *a 60 mm (2.36 in.) *b 120 mm (4.72 in.)

Laser Screw Welding - -

Laser Screw Welding - -

-

-

INSTALLATION

Symbol Meaning

Plug Weld

Cut and Join Location

Butt Weld

-

Inspect the fitting of the related parts around the new parts before welding. This affects the appearance of the finish.

-

Temporarily install the new parts and measure each part of the new parts in accordance with the body dimension diagram. (See the body dimensions)

-

If the entire supply part is not needed, remove the part of the supply part that is needed.

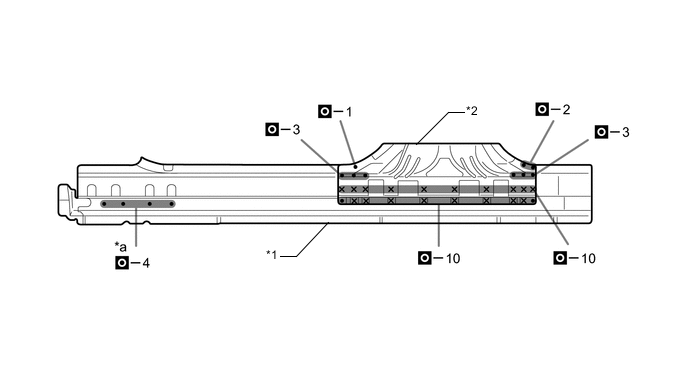

*1 CENTER BODY PILLAR REINFORCEMENT SUB-ASSEMBLY - - *a 120 mm (4.72 in.) - - -

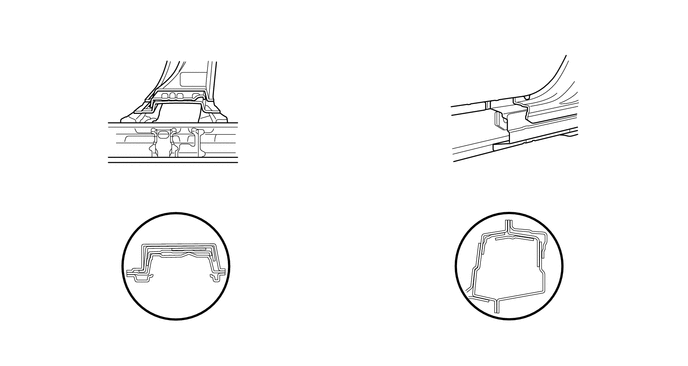

Before temporarily installing the new parts, weld the rocker reinforce sub-assembly outer and center body pillar reinforcement sub-assembly with the standard number of welding points.

*1 ROCKER REINFORCE SUB-ASSEMBLY OUTER *2 CENTER BODY PILLAR REINFORCEMENT SUB-ASSEMBLY *a Ultra High Strength Steel Welding Point - -

Laser Screw Welding - -

-

When welding 2 panels together including 1500 MPa ultra high strength steel.

*a: Plug weld Plug diameter 10 mm (0.39 in.) Wire type AWS A5.18 ER70S-3 Shield gas Metal active gas Note

Be sure to use Metal active gas (Ar 80% + CO220%) as the shield gas when plug welding.Sufficient weld strength cannot be assured when using 100% CO2shield gas.

Follow the welding conditions below when welding ultra high strength steel to assure sufficient weld strength. (When repairing this model)

-

-

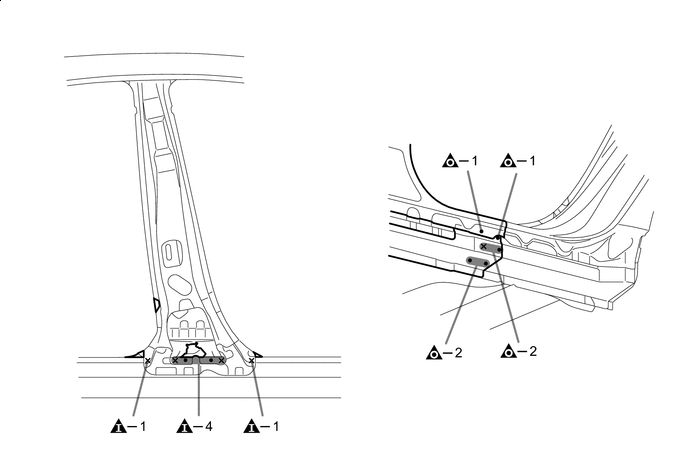

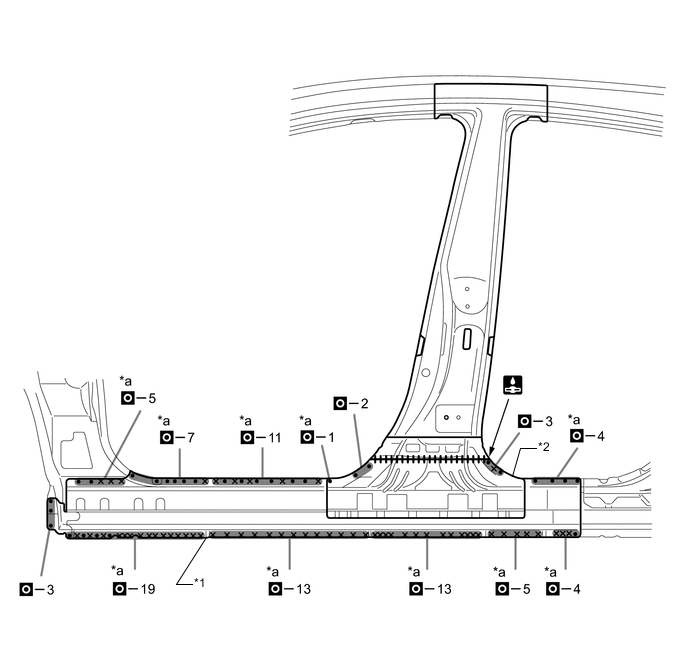

Weld the rocker reinforce sub-assembly outer and center body pillar reinforcement sub-assembly to the vehicle side.

*1 ROCKER REINFORCE SUB-ASSEMBLY OUTER *2 CENTER BODY PILLAR REINFORCEMENT SUB-ASSEMBLY *a Ultra High Strength Steel Welding Point - -

Laser Screw Welding - -

-

When welding 2 panels together including 1500 MPa ultra high strength steel.

*a: Plug weld Plug diameter 10 mm (0.39 in.) Wire type AWS A5.18 ER70S-3 Shield gas Metal active gas Note

Be sure to use Metal active gas (Ar 80% + CO220%) as the shield gas when plug welding.Sufficient weld strength cannot be assured when using 100% CO2shield gas.

Follow the welding conditions below when welding ultra high strength steel to assure sufficient weld strength. (When repairing this model)

*a Ultra High Strength Steel Welding Point - -

Laser Screw Welding - -

-

When welding 2 panels together including 1500 MPa ultra high strength steel.

*a: Plug weld Plug diameter 10 mm (0.39 in.) Wire type AWS A5.18 ER70S-3 Shield gas Metal active gas Note

Be sure to use Metal active gas (Ar 80% + CO220%) as the shield gas when plug welding.Sufficient weld strength cannot be assured when using 100% CO2shield gas.

Follow the welding conditions below when welding ultra high strength steel to assure sufficient weld strength. (When repairing this model)

-

-

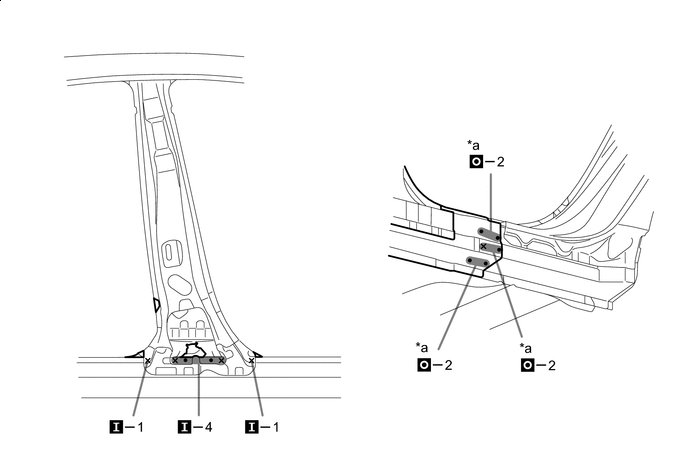

Weld the center body pillar outer to the vehicle side.

*1 CENTER BODY PILLAR OUTER - - *a Ultra High Strength Steel Welding Point - -

Laser Screw Welding - -

-

When welding more than 3 panels together including 1500 MPa ultra high strength steel. (When plug welding a third panel to 2 panels which are welded under the conditions described above.)

*a: Plug weld Plug diameter Same as the standard method (See the introduction) Wire type AWS A5.18 ER70S-3 Shield gas Metal active gas Note

Be sure to use Metal active gas (Ar 80% + CO220%) as the shield gas when plug welding.Sufficient weld strength cannot be assured when using 100% CO2shield gas.

Follow the welding conditions below when welding ultra high strength steel to assure sufficient weld strength. (When repairing this model)

-

-

After welding, apply the foamed sealing material to the corresponding parts. (See the painting/coating)

-

After welding, apply body sealer to the corresponding parts. (See the painting/coating)

-

After applying the top coat, apply anti-rust agent to the internal panel portion of the closed section structural weld points.

-