CLUTCH UNIT (for 1ZR-FAE, 2ZR-FAE) INSTALLATION

Note

When the transaxle is removed, be sure to use a new clutch release with bearing cylinder and new installation bolts. Removal of the transaxle allows the compressed clutch release with bearing cylinder to return to its original position, and dust could damage the seal of the clutch release with bearing cylinder, possibly causing clutch fluid leaks.

-

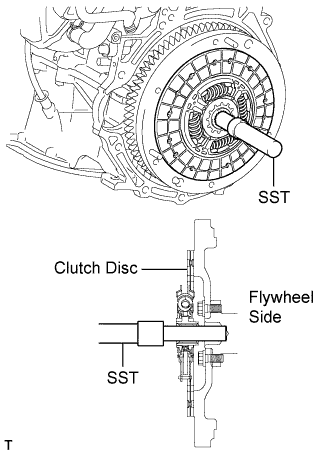

INSTALL CLUTCH DISC ASSEMBLY

-

Insert SST into the clutch disc assembly, and then attach them both to the flywheel sub-assembly.

- SST

- 09301-00210

Note

Insert the clutch disc assembly in the correct direction.

-

-

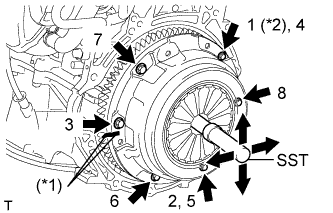

INSTALL CLUTCH COVER ASSEMBLY

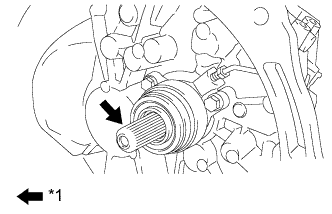

Text in Illustration *1 Matchmark *2 Temporarily Install

-

Align the matchmark on the clutch cover assembly with the one on the flywheel sub-assembly.

-

Following the order shown in the illustration, tighten the 6 bolts, starting with the bolt located near the knock pin at the top.

- SST

- 09301-00210

- Torque:

- 19 N*m { 195 kgf*cm, 14 ft.*lbf }

Tech Tips

-

Following the order in the illustration, tighten the bolts evenly one at a time.

-

Move SST up and down, right and left lightly after checking that the clutch disc assembly is in the center, and tighten the bolts.

-

-

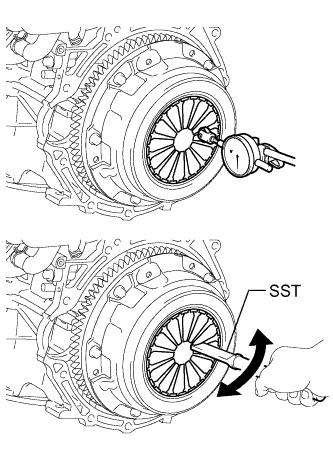

INSPECT AND ADJUST CLUTCH COVER ASSEMBLY

-

Using a dial indicator with a roller instrument, check the diaphragm spring tip alignment.

Maximum misalignment 0.5 mm (0.0196 in.) If the misalignment is more than the maximum, using SST, adjust the diaphragm spring tip alignment.

- SST

- 09333-00013

-

-

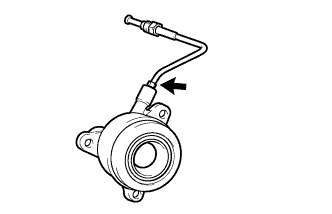

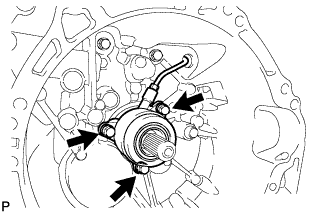

INSTALL CLUTCH RELEASE WITH BEARING CYLINDER ASSEMBLY

-

Temporarily install the clutch release cylinder to bleeder tube to a new clutch release with bearing cylinder assembly.

-

Clean and degrease all installation surfaces for the clutch release with bearing cylinder assembly.

-

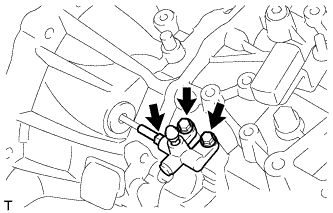

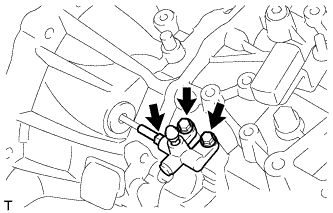

Install the clutch release with bearing cylinder assembly with 3 new bolts.

- Torque:

- 23 N*m { 229 kgf*cm, 17 ft.*lbf }

Note

-

The clutch release with bearing cylinder and installation bolts cannot be reused and must be replaced with new ones.

-

Clean and degrease all installation surfaces and make sure the clutch release with bearing cylinder fits securely with the transaxle during installation. The first bolt should be tightened by hand while holding the clutch release with bearing cylinder.

-

Make sure that none of the clutch spline grease adheres to the clutch release with bearing cylinder.

-

The clutch release with bearing cylinder cannot be disassembled.

-

Install the clutch tube boot to the manual transaxle assembly.

-

Temporarily install the clutch release cylinder to bleeder tube to the clutch release bleeder sub-assembly.

-

Temporarily install the clutch release bleeder sub-assembly with the 2 bolts.

-

Using a union nut wrench, install the clutch release cylinder to bleeder tube to the clutch release with bearing cylinder assembly.

- Torque:

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

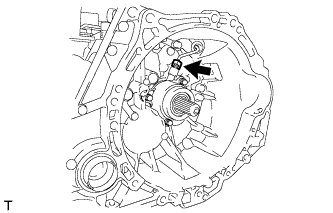

Text in Illustration *1 Clutch spline grease Apply clutch spline grease to the input shaft spline.

Grease Toyota Genuine Clutch Spline Grease or equivalent

-

-

REMOVE CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

-

Separate the clutch release cylinder to bleeder tube from the clutch release bleeder sub-assembly.

-

Remove the 2 bolts and clutch release bleeder sub-assembly.

-

-

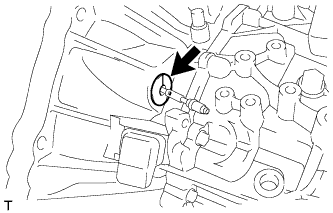

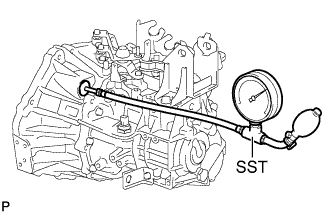

INSPECT CLUTCH PIPE LINE

-

Using SST, apply a pressure of 100 kPa (1.0 kgf/cm2, 15 psi) to the clutch pipe location shown in the illustration and confirm that pressure is maintained for 15 seconds or more.

- SST

- 09992-00242

If the pressure drops, replace the clutch release cylinder to bleeder tube.

-

-

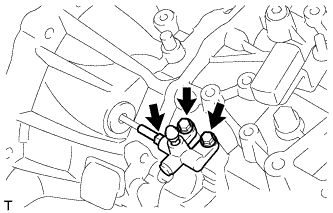

INSTALL CLUTCH RELEASE BLEEDER SUB-ASSEMBLY

-

Temporarily install the clutch release cylinder to bleeder tube to the clutch release bleeder sub-assembly.

-

Install the clutch release bleeder sub-assembly with the 2 bolts.

- Torque:

- 17 N*m { 170 kgf*cm, 12 ft.*lbf }

-

Using a union nut wrench, install the clutch release cylinder to bleeder tube.

- Torque:

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

-

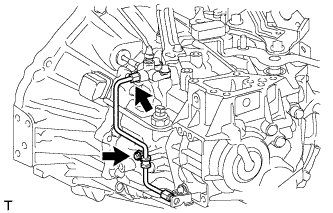

INSTALL CLUTCH RELEASE BLEEDER TO FLEXIBLE HOSE TUBE

-

for 1ZR-FAE:

-

Using a union nut wrench, install the clutch release bleeder to flexible hose tube to the clutch release bleeder sub-assembly.

- Torque:

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

Install the clamp to the manual transaxle with the bolt.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

-

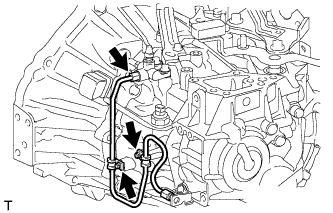

for 2ZR-FAE:

-

Using a union nut wrench, install the clutch release bleeder to flexible hose tube to the clutch release bleeder sub-assembly.

- Torque:

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

Install the 2 clamps to the manual transaxle with the 2 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

-

-

INSTALL MANUAL TRANSAXLE ASSEMBLY

-

for 1ZR-FAE:

Install the manual transaxle assembly Click here.

-

for 2ZR-FAE:

Install the manual transaxle assembly Click here.

-