FUEL SYSTEM ON-VEHICLE INSPECTION

-

CHECK FUEL PUMP OPERATION AND INSPECT FOR FUEL LEAK

-

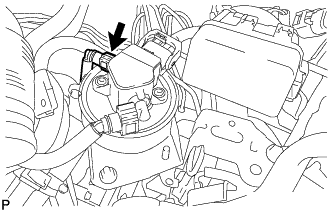

Check fuel pump operation.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

Note

Do not start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Actuator Test of FPC (EU5).

-

Check for pressure in the fuel inlet tube from the fuel line. Check that sounds of fuel flowing from the fuel tank can be heard. If no sounds can be heard, check the No. 1 integration relay, fuel suction with pump and gauge tube assembly, ECM and wiring connectors.

-

-

Inspect for fuel leaks.

-

Check that there are no fuel leaks from the fuel system after doing any maintenance or repairs. If there is a fuel leak, repair or replace parts as necessary.

-

-

Turn the ignition switch off.

-

Disconnect the GTS from the DLC3.

-

-

CHECK FUEL PRESSURE

-

Measure the battery voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition Positive (+) terminal - Negative (-) terminal Ignition switch off 11 to 14 V -

Disconnect the cable from the negative (-) battery terminal.

-

Remove the No. 1 fuel filter protector Click here.

-

Disconnect the No. 3 fuel hose from the fuel filter assembly Click here.

-

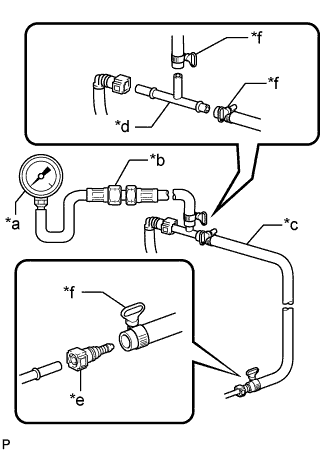

Text in Illustration *a SST (Pressure Gauge) *b SST (Hose Joint) *c SST (Hose) *d SST (T Joint) *e SST (Fuel Tube Connector) *f SST (Hose Band) Install SST (pressure gauge) using other SST as shown in the illustration.

- SST

- 09268-45101 ( 09268-41250, 09268-41260, 09268-41280, 09268-41500, 09268-41700, 95336-08070 )

Note

Do not use SST that were used for working with gasoline.

Use different SST when working with gasoline and diesel fuel.

-

Clean up any spilled diesel fuel.

-

Connect the cable to the negative (-) battery terminal.

-

Connect the GTS to the DLC3.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Actuator Test of FPC (EU5).

-

Measure the fuel pressure.

Standard fuel pressure 450 to 700 kPa (4.6 to 7.1 kgf/cm2, 65 to 102 psi)

-

If the fuel pressure is higher than the standard value, check the fuel filter.

-

If the fuel pressure is less than the standard value, check the fuel hoses, connections and fuel pump.

-

-

Disconnect the GTS from the DLC3.

-

Start the engine.

-

Measure the fuel pressure at idle.

Standard fuel pressure 450 to 700 kPa (4.6 to 7.1 kgf/cm2, 65 to 102 psi) -

Stop the engine.

-

Reconnect the No. 3 fuel hose to the fuel filter assembly Click here.

-

Install the No. 1 fuel filter protector Click here.

-

Inspect for fuel leaks (Step 1).

-

-

CHECK FUEL PRESSURE (for High Pressure)

-

Read the Data List.

Note

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

Tech Tips

Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

-

Warm up the engine.

-

Turn the ignition switch off.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Target Common Rail Pressure and Common Rail Pressure.

-

Check that the internal fuel pressure of the common rail is within the specification below.

OK Common Rail Pressure is within +/-10000 kPa of Target Common Rail Pressure when the engine is idling and running at 3000 rpm without load.

-

-

-

CHECK FUEL FILTER WARNING LIGHT AND DRAIN WATER

-

Check the fuel filter multi-information display.

Note

When the fuel system warning is displayed on the multi-information display, replace the fuel filter Click here or drain the water in the fuel filter.

-

Drain water.

-

Remove the air cleaner cap sub-assembly with air cleaner hose assembly Click here.

-

Remove the air cleaner element sub-assembly.

-

Remove the air cleaner case sub-assembly Click here.

-

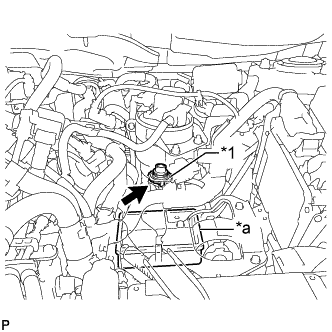

Text in Illustration *1 Drain Cock *a Container Place the container under the fuel filter assembly and loosen the drain cock to drain the water.

-

Tighten the drain cock by hand.

Note

Do not use any tools in this procedure.

-

Install the air cleaner case sub-assembly Click here.

-

Install the air cleaner element sub-assembly.

-

Install the air cleaner cap sub-assembly with air cleaner hose assembly Click here.

-

-