ECD SYSTEM (for DPF) INITIALIZATION

-

INITIALIZATION PROCEDURE FOR DIESEL THROTTLE BODY ASSEMBLY, ELECTRIC EGR CONTROL VALVE ASSEMBLY AND TURBOCHARGER

Tech Tips

When the diesel throttle body assembly, electric EGR control valve assembly or turbocharger sub-assembly is replaced, perform initialization

-

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the ignition switch off and wait for 30 seconds or more.

-

Turn the ignition switch to ON and wait for 10 seconds or more.

-

-

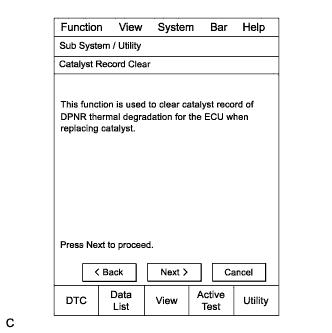

CATALYST RECORD OF DPF THERMAL DETERIORATION CLEAR FUNCTION

Tech Tips

When the DPF catalyst is replaced, the catalyst record of DPF thermal deterioration stored in the ECM must be cleared.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

-

Enter the menu options in this order: Powertrain / Engine and ECT / Utility / Catalyst Record Clear.

-

Press "Next".

-

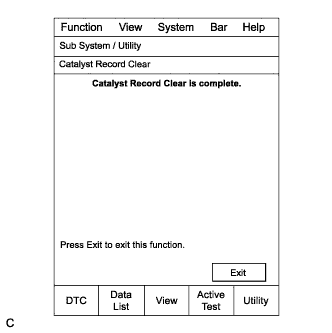

Press "Exit".

-

-

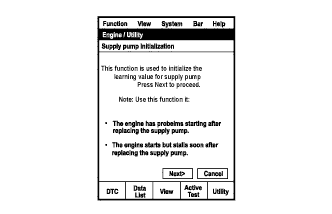

SUPPLY PUMP INITIALIZATION PROCEDURE

Tech Tips

After replacing the supply pump and/or ECM:

-

If the engine is defective or stalls immediately after startup, the learned values of the ECM must be initialized. The engine can be initialized through the intelligent tester or by short circuiting DLC3 terminals.

-

If the engine starts normally, initialization is not necessary. Perform steps procedure "A" and procedure "B" only.

-

Connect the intelligent tester to the DLC3.

-

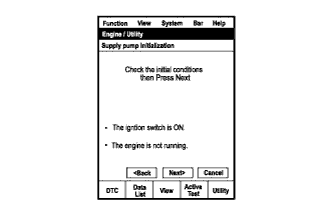

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the intelligent tester on.

-

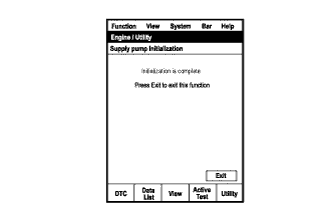

Enter the following menus: Powertrain / Engine and ECT / Utility / Supply Pump Initialization.

-

Press "Next".

-

Press "Next".

-

Press "Exit".

-

Start the engine to check if the initialization is complete. If the engine cannot be started, repeat the initialization procedures from the beginning. (Procedure "A")

-

Idle the engine for at least 1 minute under the following conditions: (Procedure "B")

-

The engine coolant temperature is 60°C (140°F) or higher.

-

The fuel temperature is 20°C (68°F) or higher.

Note

Do not race the engine immediately after starting the engine. After warming up the engine, racing the engine is acceptable.

Tech Tips

-

The engine coolant temperature can be estimated by touching the outlet hose.

-

The fuel temperature can be estimated by using the ambient temperature as a substitute.

-

If the engine coolant temperature is difficult to estimate, use the intelligent tester and enter the following menus: Powertrain / Engine and ECT / Data List / Coolant Temp.

-

-

Initialization is complete.

-

-

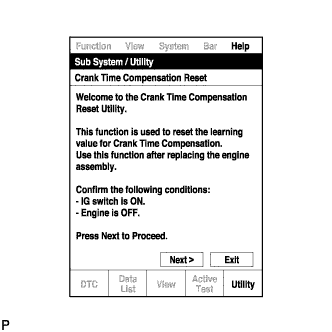

CRANK TIME COMPENSATION RESET FUNCTION

-

This procedure uses the intelligent tester to perform "Crank Time Compensation Reset".

-

When replacing the timing rotor (engine assembly), perform "Crank Time Compensation Reset".

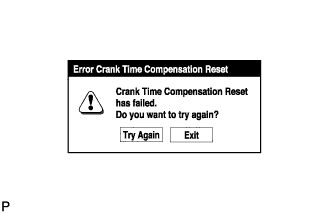

Tech Tips

-

If an error occurs during compensation reset, check the vehicle condition, and then perform compensation reset again.

-

A communication malfunction may occur if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / Crank Time Compensation Reset.

-

When the first screen is displayed, check the vehicle condition and push "Next".

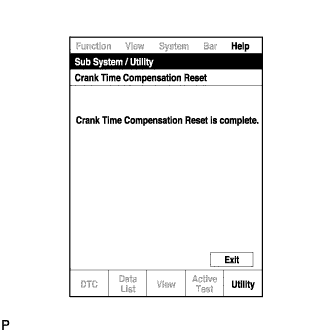

-

When the screen indicating reset completion is displayed, push "Exit".

-

-

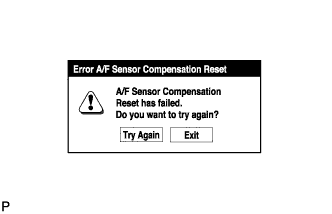

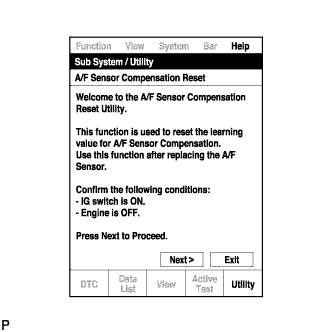

A/F SENSOR COMPENSATION RESET FUNCTION

-

This procedure uses the intelligent tester to perform "A/F Sensor Compensation Reset".

-

When replacing the A/F sensor, replace the sensor and then perform "A/F Sensor Compensation Reset".

Tech Tips

-

If an error occurs during compensation reset, check the vehicle condition, and then perform compensation reset again.

-

A communication malfunction may occur if there is a problem with the ECM, a wire harness or the connection to the DLC3. If the wire harnesses and the connection to the DLC3 are inspected and found to be normal, the ECM may be malfunctioning.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

Note

Do not start the engine.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / A/F Sensor Compensation Reset.

-

When the first screen is displayed, check the vehicle condition and push "Next".

-

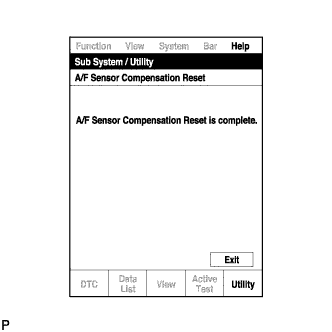

When the screen indicating reset completion is displayed, push "Exit".

-