ECD SYSTEM (for CCo) PRECAUTION

-

IGNITION SWITCH EXPRESSION

Tech Tips

The type of ignition switch used on this model differs according to the specifications of the vehicle. The expressions listed in the table below are used in this section.

Expression Ignition Switch (position) Engine Switch (condition) Ignition Switch off Off Off Ignition Switch ON ON On (IG) Ignition Switch ACC ACC On (ACC) Engine Start START Start -

INITIALIZATION AND REGISTRATION

Note

When replacing the ECM and/or any other components in the following chart, perform the corresponding utility items.

Tech Tips

When the ECM and other component(s) are replaced at the same time, perform the following utility items by following the instructions shown on the tester display, starting with the ECM.

Replacement Part Utility Item ECM

-

Learning Values Save Click here

-

Learning Values Write Click here

Engine assembly

-

Clear Crank Time Compensation Data Click here

-

Input Injector Compensation Code Click here

-

Pilot Quantity Learning Click here

Crankshaft position sensor plate Clear Crank Time Compensation Data Click here

Supply pump Supply Pump Initialization Click here

Injector

-

Input Injector Compensation Code Click here

-

After that perform the Pilot Quantity Learning Click here

Tech Tips

When the ECM must be replaced, before replacing the ECM, perform the "Learning Values Save" function using the intelligent tester. Then after installing the new ECM, perform all of the initializations/registrations for the "Learning Values Write" function by following the instructions shown on the tester display.

-

-

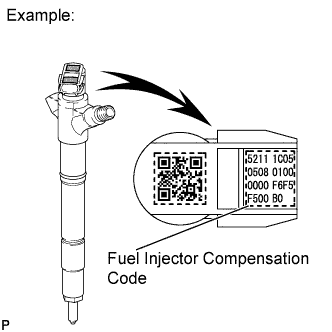

INJECTOR COMPENSATION CODE

Tech Tips

-

Each injector has different fuel injection characteristics. In order to optimize fuel injection performance, the ECM compensates for these differences by adjusting the fuel injection duration of each injector according to its compensation code. Injector compensation codes are unique, 30-digit, alphanumeric values printed on the head portion of each injector.

-

If an incorrect injector compensation code is input into the ECM, the engine may rattle or engine idling may become rough. In addition, engine failure may occur and the life of the engine may be shortened.

-

When an injector is replaced, the injector compensation code must be input into the ECM Click here.

-

When the ECM is replaced, all of the existing injector compensation codes must be input into the new ECM Click here.

-

-

PILOT QUANTITY LEARNING

Tech Tips

-

By performing "Pilot Quantity Learning", the injection volume for each cylinder is precisely adjusted so that the engine runs smoothly. The "Pilot Quantity Learning" information is stored in the EEPROM of the ECM.

-

If an incorrect pilot quantity learning value is input into the ECM, the engine may rattle or engine idling may become rough.

-

When an injector is replaced, the injector compensation code must to be input to the ECM and then perform the pilot quantity learning Click here.

-

When the ECM is replaced, all of the existing injector pilot quantity learning values must be input into the new ECM Click here.

-

-

DIFFICULT TO START ENGINE, ENGINE STALLING, BLACK SMOKE EMITTED ROUGH IDLING, EXCESSIVE ENGINE VIBRATION, ENGINE KNOCKING, LACK OF POWER OR HESITATION

-

Check if the customer problem is described below. If so, refer to the appropriate troubleshooting section.

-

Engine is difficult to start or stalling.

-

Black smoke is emitted.

-

Rough Idling or Excessive Engine Vibrations.

-

Engine Knocking or Rattling.

-

Lack of Power or Hesitation.

-

-

-

WHEN USING INTELLIGENT TESTER

CAUTION:

-

Observe the following items for safety reasons:

-

Read its instruction books before using the tester.

-

Prevent the tester cable from being caught on the pedals, shift lever and steering wheel when driving with the tester connected to the vehicle.

-

When driving the vehicle for testing purposes using the tester, two persons are required. One drives the vehicle and the other operates the tester.

-