SFI SYSTEM, Diagnostic DTC:P2A00

DESCRIPTION

Tech Tips

Sensor 1 refers to the sensor mounted in front of the Three-Way Catalytic Converter (TWC) and located near the engine assembly.

Refer to DTC P2195 Click here.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P2A00 | Calculated value of air fuel ratio sensor response rate deterioration level less than threshold (2 trip detection logic) |

|

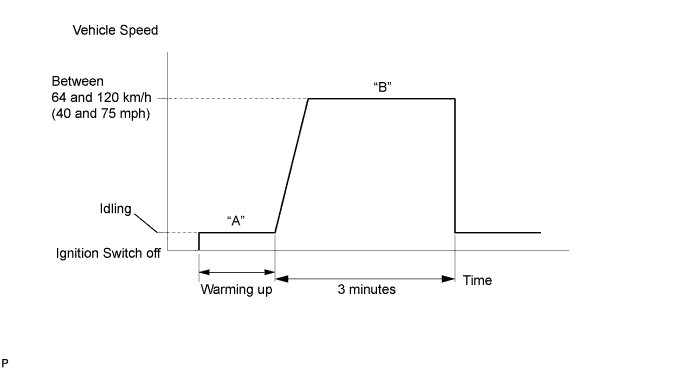

CONFIRMATION DRIVING PATTERN

Tech Tips

Performing this confirmation pattern will activate the air fuel ratio sensor response monitor.

-

Connect an intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / DTC / Clear.

-

Clear DTCs Click here.

-

Start the engine and warm it up. (Proceed to "A")

-

Drive the vehicle at a constant speed of between 64 km/h and 120 km/h (40 mph and 75 mph) for 3 minutes or more. (Proceed to "B")

-

Turn the ignition switch off.

-

Repeat steps Procedure "A" and "B" above again.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Check if any DTCs (any pending DTCs) are output.

WIRING DIAGRAM

Refer to DTC P2195 Click here.

INSPECTION PROCEDURE

Tech Tips

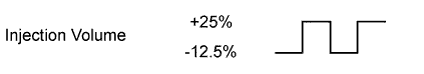

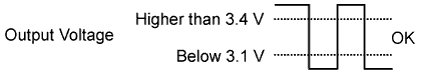

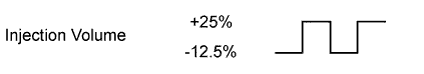

Malfunctioning areas can be identified by performing the Control the Injection Volume for A/F sensor function provided in the Active Test. The Control the Injection Volume for A/F sensor function can help to determine whether the Air-Fuel Ratio (A/F) sensor, Heated Oxygen (HO2) sensor and other potential trouble areas are malfunctioning.

The following instructions describe how to conduct the Control the Injection Volume for A/F sensor operation using the intelligent tester.

-

Connect the intelligent tester to the DLC3.

-

Start the engine and turn the tester on.

-

Warm up the engine at an engine speed of 2500 rpm for approximately 90 seconds.

-

On the tester, enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume for A/F sensor.

-

Perform the Active Test operation with the engine in an idling condition (press the RIGHT or LEFT button to change the fuel injection volume.)

-

Monitor the output voltages of the A/F and HO2 sensors (AFS Voltage B1 S1 and O2S B1 S2) displayed on the tester.

Tech Tips

-

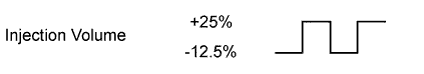

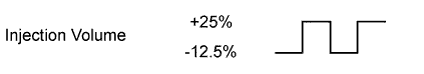

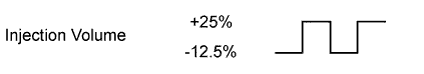

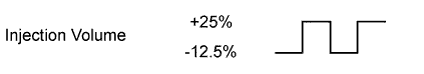

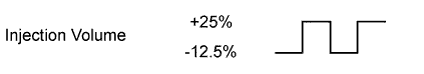

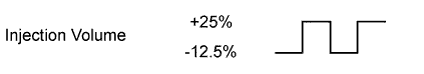

The Control the Injection Volume for A/F sensor operation lowers the fuel injection volume by 12.5% or increases the injection volume by 25%.

-

Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

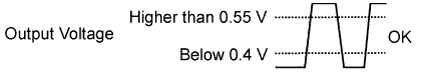

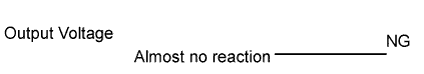

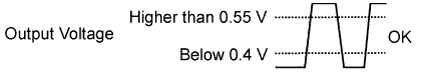

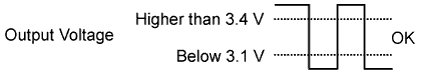

| Tester Display (Sensor) | Injection Volume | Status | Voltage |

|---|---|---|---|

| AFS Voltage B1 S1 (A/F) |

+25% | Rich | Below 3.1 V |

| AFS Voltage B1 S1 (A/F) |

-12.5% | Lean | Higher than 3.4 V |

| O2S B1 S2 (HO2) |

+25% | Rich | Higher than 0.55 V |

| O2S B1 S2 (HO2) |

-12.5% | Lean | Below 0.4 V |

Note

The air fuel ratio sensor has an output delay of a few seconds and the heated oxygen sensor has a maximum output delay of approximately 20 seconds.

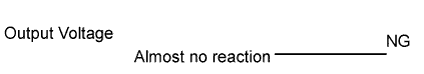

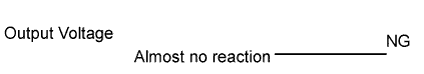

| Case | A/F Sensor (Sensor 1) Output Voltage | HO2 Sensor (Sensor 2) Output Voltage | Main Suspected Trouble Area |

|---|---|---|---|

| 1 |   |

|

- |

| 2 |   |

|

|

| 3 |   |

|

|

| 4 |   |

|

|

-

Following the Control the Injection Volume for A/F sensor procedure enables technicians to check and graph the voltage outputs of both the A/F and HO2 sensors.

-

To display the graph, enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Volume for A/F Sensor / AFS Voltage B1 S1 and O2S B1 S2.

Tech Tips

-

DTC P2A00 may be set when the air fuel ratio is stuck rich or lean.

-

A low air fuel ratio sensor voltage could be caused by a rich air fuel mixture. Check for conditions that would cause the engine to run rich.

-

A high air fuel ratio sensor voltage could be caused by a lean air fuel mixture. Check for conditions that would cause the engine to run lean.

-

Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

PROCEDURE

-

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P2A00)

-

Connect an intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read DTCs.

Result Result Proceed to P2A00 A P2A00 and other DTCs B Tech Tips

If any DTCs relating to the A/F sensor (DTCs for the A/F sensor heater or A/F sensor admittance) are output, troubleshoot those DTCs first.

B

GO TO DTC CHART Click here

A

-

-

INSPECT AIR FUEL RATIO SENSOR (HEATER RESISTANCE)

-

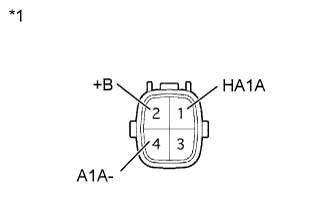

Text in Illustration *1 Component without harness connected

(Air Fuel Ratio Sensor)

Disconnect the air fuel ratio sensor connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 1 (HA1A) - 2 (+B) 20°C (68°F) 1.8 to 3.4 Ω 1 (HA1A) - 4 (A1A-) Always 10 kΩ or higher -

Reconnect the air fuel ratio sensor.

NG

REPLACE AIR FUEL RATIO SENSOR Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (AIR FUEL RATIO SENSOR - ECM)

-

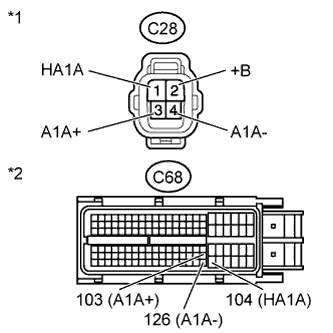

Text in Illustration *1 Front view of wire harness connector

(to Air Fuel Ratio Sensor)

*2 Front view of wire harness connector

(to ECM)

Disconnect the air fuel ratio sensor connector.

-

Turn the ignition switch to ON.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition C28-2 (+B) - Body ground Ignition switch ON 11 to 14 V -

Turn the ignition switch off.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for open) Tester Connection Condition Specified Condition C28-3 (A1A+) - C68-103 (A1A+) Always Below 1 Ω C28-4 (A1A-) - C68-126 (A1A-) Always Below 1 Ω C28-1 (HA1A) - C68-104 (HA1A) Always Below 1 Ω Standard Resistance (Check for short) Tester Connection Condition Specified Condition C28-3 (A1A+) or C68-103 (A1A+) - Body ground Always 10 kΩ or higher C28-4 (A1A-) or C68-126 (A1A-) - Body ground Always 10 kΩ or higher C28-1 (HA1A) or C68-104 (HA1A) - Body ground Always 10 kΩ or higher -

Reconnect the ECM connector.

-

Reconnect the air fuel ratio sensor connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (AIR FUEL RATIO SENSOR - ECM)

OK

-

-

PERFORM CONFIRMATION DRIVING PATTERN

NEXT

-

CHECK WHETHER DTC OUTPUT RECURS (DTC P2A00)

-

Connect an intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read DTCs.

Result Result Proceed to P2A00 A No output B

B

CHECK FOR INTERMITTENT PROBLEMS Click here

A

-

-

REPLACE AIR FUEL RATIO SENSOR

-

Replace the air fuel ratio sensor Click here.

NEXT

-

-

PERFORM CONFIRMATION DRIVING PATTERN

NEXT

-

CHECK WHETHER DTC OUTPUT RECURS (DTC P2A00)

-

Connect an intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read DTCs.

Result Result Proceed to No output A P2A00 B

B

REPAIR OR REPLACE CAUSE OF EXTREMELY RICH OR LEAN ACTUAL AIR FUEL RATIO Click here

A

END

-