REAR BRAKE INSPECTION

-

INSPECT BRAKE CYLINDER AND PISTON

-

Inspect the cylinder bore and the piston for rust or scoring. If necessary, replace the rear disc brake cylinder assembly and piston.

-

-

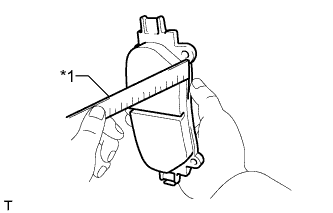

INSPECT PAD LINING THICKNESS

-

Text in Illustration *1 Ruler Using a ruler, measure the pad lining thickness.

Standard thickness 10.0 mm (0.394 in.) Minimum thickness 1.0 mm (0.0394 in.) If the pad lining thickness is less than the minimum, replace the brake pads.

Tech Tips

Be sure to check wear of the rear disc after replacing the brake pads with new ones.

-

-

INSPECT REAR DISC BRAKE PAD SUPPORT PLATE

-

Inspect the rear disc brake pad support plate. If necessary, replace the rear disc brake pad support plate.

Tech Tips

Make sure that it has sufficient rebound, and has no deformation, cracks or wear, and all rust and dirt are cleaned off.

-

-

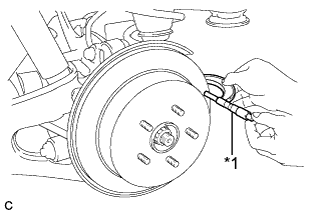

INSPECT DISC THICKNESS

-

Text in Illustration *1 Micrometer Using a micrometer, measure the disc thickness.

Rear Disc Thickness Rear Disc Type Standard Thickness Minimum Thickness Solid 10.0 mm (0.394 in.) 8.5 mm (0.335 in.) Ventilated 18.0 mm (0.709 in.) 16.5 mm (0.650 in.) If the disc thickness is less than the minimum, replace the rear disc.

-

-

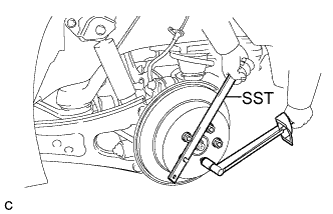

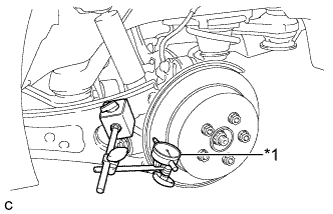

INSPECT DISC RUNOUT

-

Using SST to hold the rear disc, tighten the rear disc with the 5 hub nuts.

- SST

- 09330-00021

- Torque:

- 103 N*m { 1050 kgf*cm, 76 ft.*lbf }

-

Text in Illustration *1 Dial Indicator Using a dial indicator, measure the disc runout 10 mm (0.394 in.) away from the outer edge of the rear disc.

Maximum disc runout 0.15 mm (0.00591 in.) Note

-

Keep the magnet of the dial indicator away from the axle hub and speed sensor.

-

Install the dial indicator to the rear trailing arm assembly.

Tech Tips

If the runout exceeds the maximum value, change the installation position of the disc on the rear axle hub to minimize the runout. If the runout exceeds the maximum even after the installation position is changed, check the bearing play in the axial direction and the axle hub runout Click here. If the bearing play and the axle hub runout are normal and if the disc thickness is not within the specified range, grind the disc. If the disc thickness is less than the minimum, replace the disc.

-

-

Remove the 5 hub nuts and the rear disc.

-