HYBRID CONTROL SYSTEM, Diagnostic DTC:P0BCD-315, P0BD0-314

| DTC Code | DTC Name |

|---|---|

| P0BCD-315 | Generator Inverter Temperature Sensor Circuit Range / Performance |

| P0BD0-314 | Generator Inverter Temperature Sensor Circuit Intermittent / Erratic |

DESCRIPTION

The MG ECU, which is built into in the inverter with converter assembly, detects the temperature of the generator inverter using the temperature sensor built into the generator inverter. If necessary, the MG ECU will limit inverter output to help prevent generator inverter overheating. The power management control ECU also detects malfunctions in the sensor based on the temperature sensor values. The inverter with converter assembly detects malfunctions in the generator inverter temperature sensor and its wiring.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0BCD-315 | Generator inverter temperature calculated by the power management control ECU is different from the actual temperature for 10 seconds or more, and the generator inverter temperature is too high. (1 trip detection logic) |

|

| P0BD0-314 | Sudden change in generator inverter temperature sensor output or hunting: Generator inverter temperature is high and either of the following conditions is met:

(1 trip detection logic) |

|

Tech Tips

*: If only DTC P0BD0-314 is output, a temperature sensor malfunction is more likely to be the cause than a sudden change in actual temperature.

| DTC No. | Data List |

|---|---|

| P0BCD-315 |

|

| P0BD0-314 |

INSPECTION PROCEDURE

CAUTION:

-

Before inspecting the high-voltage system or disconnecting the low voltage connector of the inverter with converter assembly, take safety precautions such as wearing insulated gloves and removing the service plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work Click here.

Tech Tips

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

Note

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work Click here.

Tech Tips

After the repair, clear the DTCs and perform the following procedure to check that DTCs are not output.

-

Turn the power switch on (READY) and wait for 90 seconds or more.

-

Drive the vehicle for approximately 10 minutes referring to the following freeze frame data or Data List items: "Vehicle Spd".

PROCEDURE

-

CHECK DTC OUTPUT (HYBRID CONTROL)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Check for DTCs.

Result Result Proceed to P0BCD-315 or P0BD0-314 only is output, or DTCs except the ones in the table below are also output. A Any of the following DTCs are also output. B DTC No. Relevant Diagnosis P0A93-346 Inverter Cooling System Performance P0C73-776 Motor Electronics Coolant Pump "A" Control Performance P314A-828 Inverter Coolant Pump Speed Signal Tech Tips

P0BCD-315 or P0BD0-314 may be stored due to a malfunction which also causes DTCs in the preceding table to be stored. In this case, first troubleshoot the output DTCs in the preceding table. Then, perform a test to attempt to reproduce the problems, and check that no DTCs are output.

-

Turn the power switch off.

B

GO TO DTC CHART (HYBRID CONTROL SYSTEM) Click here

A

-

-

CHECK CONNECTOR CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY CONNECTOR)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Check connection condition of the low voltage connector of the inverter with converter assembly and the contact pressure of each terminal. Check the terminals for deformation, and check the connector for water ingress and foreign matter Click here.

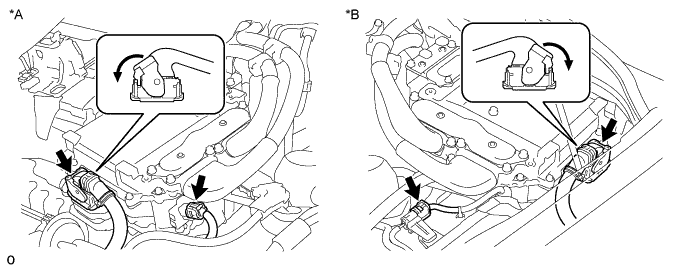

Text in Illustration *A for LHD *B for RHD Note

Before disconnecting the connector, confirm that it is properly connected by checking that the locking claws are engaged and that the connector does not pull out.

OK - The connector is connected securely. - The terminals are not deformed and are connected securely. - No water or foreign matter in the connector. Result Result Proceed to OK A NG (The connector is not connected securely.) B NG (The terminals are not making secure contact or are deformed, or water or foreign matter exists in the connector.) C Tech Tips

When connecting the connector, insert it with the locking lever in the raised position. Rotate the lever downward and make sure that the connector is pulled into its socket. When the locking lever is in its fully closed position, a click will be heard as its locking claws engage. After the click is heard, pull up on the connector to confirm that it is properly connected.

B

CONNECT SECURELY

C

REPAIR OR REPLACE HARNESS OR CONNECTOR

A

-

-

CHECK QUANTITY OF HV COOLANT

-

Check the HV coolant level in the inverter reserve tank.

-

Check for HV coolant leaks.

Result Result Proceed to No leaks are found and coolant level in the inverter reserve tank assembly is above the low line. A No leaks are found and coolant level in the inverter reserve tank assembly is below the low line. B HV coolant leaks are evident. C Note

The inverter water pump with motor assembly has a protection function that activates when there is an HV coolant leak. Therefore, it is not necessary to replace the inverter water pump with motor assembly unless the cause of the HV coolant leak is the inverter water pump with motor assembly.

Tech Tips

After repairing the HV coolant leaks and adding coolant, perform the "(Inverter) " Active Test (HV Active Test item) and the "Control the Electric Cooling Fan" Active Test (Engine Active Test item) and make sure that there are no malfunctions.

B

ADD HV COOLANT

C

INSPECT FOR HV COOLANT LEAK AND ADD HV COOLANT

A

-

-

CHECK COOLANT HOSE

-

Check that the cooling system hoses are not kinked or clogged.

NG

REPAIR OR REPLACE COOLANT HOSE

OK

-

-

PERFORM ACTIVE TEST USING GTS (CONTROL THE ELECTRIC COOLING FAN)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Electric Cooling Fan.

-

Perform the "Control the Electric Cooling Fan" Active Test.

OK The cooling fan rotates. -

Turn the power switch off.

NG

CHECK COOLING FAN SYSTEM Click here

OK

-

-

CHECK HV COOLANT (CHECK FOR CONDITIONS THAT MAY HAVE CAUSED FREEZING)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Read the freeze frame data Ambient Temperature using the GTS.

-

Check if the freeze frame data item Ambient Temperature is below the freezing temperature of the HV coolant.

Result Result Proceed to Ambient Temperature value is below freezing temperature of the HV coolant. A Ambient Temperature value is above freezing temperature of the HV coolant. B Tech Tips

-

HV coolant (SLLC) with a 30% concentration freezes at -15°C (5°F) and HV coolant (SLLC) with a 50% concentration freezes at -35°C (-31°F).

-

If the HV coolant freezes in the HV radiator or HV water pump, the coolant temperature in the inverter with converter assembly rises because the HV coolant cannot circulate. As a result, a DTC may be stored.

-

A DTC is stored when the water pump impeller cannot rotate due to freezing of the HV coolant.

-

If DTCs are output due to freezing of the LLC, the problem symptom cannot be reproduced. Check the LLC replacement history and whether the LLC was frozen based on the ambient temperature when the DTCs were stored.

-

-

Turn the power switch off.

B

REPLACE INVERTER WITH CONVERTER ASSEMBLY Click here

A

-

-

REPLACE HV COOLANT

-

Replace the HV coolant with coolant having an appropriate concentration (appropriate freeze point) for the vehicle usage conditions Click here.

NEXT

COMPLETED

-