SFI SYSTEM, Diagnostic DTC:P0087

DESCRIPTION

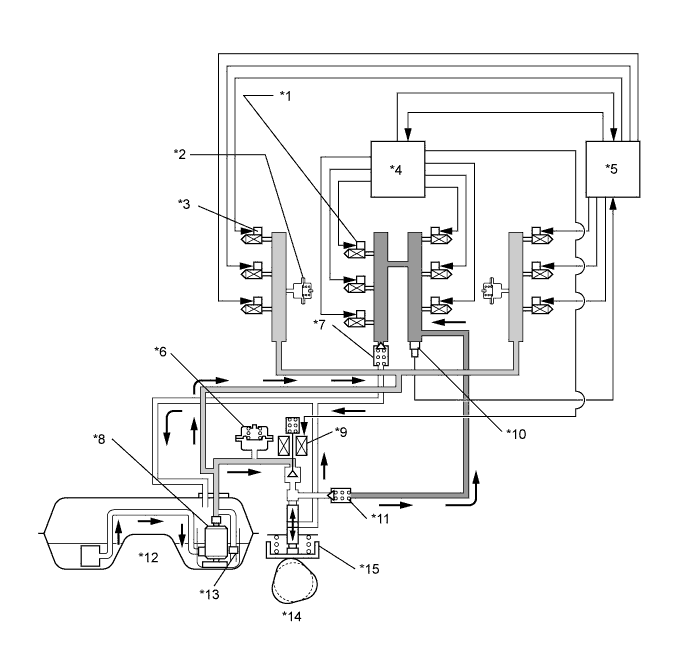

The high-pressure fuel system consists of the spill control valve, pump plunger, check valve, relief valve and fuel pressure sensor. The spill control valve opens and closes the low-pressure fuel line (from the fuel tank), the pump plunger (operated by the camshaft) pressurizes fuel, the check valve mechanically opens and closes the high pressure fuel line (to the fuel delivery pipe), the relief valve prevents fuel pressure from becoming extremely high, and the fuel pressure sensor located on the fuel delivery pipe monitors fuel pressure.

The fuel pump for high pressure is installed to the cylinder head cover (bank 1) and is driven by the cam located at the rear end of the exhaust camshaft.

The plunger moves up and down by the camshaft rotations, and produces a vacuum to suck fuel and pressurizes the fuel. This fuel then pushes the check valve open and flows into the fuel delivery pipe. The ECM opens and closes the spill control valve to regulate the fuel pressure to the target fuel pressure of 4 to 13 MPa (40.8 to 132.6 kgf/cm2, 580 to 1886 psi). In order to obtain and maintain the target pressure, the ECM monitors the fuel pressure using the fuel pressure sensor and performs the feedback control.

If the internal fuel pressure of the fuel delivery pipe exceeds the standard pressure of 15.3 MPa (156.0 kgf/cm2, 2219 psi), the fuel relief valve installed on gateway of the fuel delivery pipe discharges the fuel pressure and then returns the fuel back to the fuel tank.

| *1 | Injector (for Direct Injection) | *2 | Pulsation Damper |

| *3 | Injector (for Port Injection) | *4 | EDU |

| *5 | ECM | *6 | Pulsation Damper |

| *7 | Relief Valve | *8 | Fuel Pump (for Low Pressure) |

| *9 | Spill Control Valve | *10 | Fuel Pressure Sensor |

| *11 | Check Valve | *12 | Fuel Tank |

| *13 | Pressure Regulator | *14 | Exhaust Camshaft |

| *15 | Fuel Pump (for High Pressure) | - | - |

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0087 | Despite ECM commanding that the high pressure fuel pump opens the spill valve, fuel pressure decreases 5 MPa (51.0 kgf/cm2, 725 psi) while the engine is not idling, or 3 MPa (30.6 kgf/cm2, 435 psi) while the engine is idling from target fuel pressure for about 10 seconds (1 trip detection logic) |

|

MONITOR DESCRIPTION

If the fuel pressure decreases even after the ECM commands the high-pressure fuel pump to close the spill control valve, a DTC is output.

MONITOR STRATEGY

| Required sensors/Components | Fuel pressure sensor |

| Frequency of operation | Continuous |

CONFIRMATION DRIVING PATTERN

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Record the Freeze Frame Data.

-

Clear the DTCs (even if no DTCs are stored, perform the clear DTC procedure) Click here.

-

Turn the engine switch off and wait for at least 30 seconds.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Based on engine speed, engine load and other freeze frame data stored in the ECM, reproduce the conditions present when the DTC was stored.

-

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

-

Read the DTC.

Tech Tips

-

If a DTC is output, the system is malfunctioning.

-

If a DTC is not output, perform the following procedure.

-

-

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

-

Input the DTC: P0087.

-

Check the DTC judgment result.

GTS Display Description NORMAL

-

DTC judgment completed

-

System normal

ABNORMAL

-

DTC judgment completed

-

System abnormal

INCOMPLETE

-

DTC judgment not completed

-

Perform driving pattern after confirming DTC enabling conditions

N/A

-

Unable to perform DTC judgment

-

Number of DTCs which do not fulfill DTC preconditions has reached ECU's memory limit

Tech Tips

-

If the judgment result shown ABNORMAL, the system has a malfunction.

-

If the judgment result shows NORMAL, the system is normal.

-

INSPECTION PROCEDURE

Tech Tips

Read freeze frame data using the GTS. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was moving or stationary, whether the engine was warmed up or not, whether the air fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction.

PROCEDURE

-

CHECK FUEL LEAK (HIGH PRESSURE SIDE)

-

Check around and beneath the car for fuel leaks, fumes, etc.

OK No fuel leaks present.

NG

REPAIR OR REPLACE FUEL LEAK POINT

OK

-

-

CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0087)

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

-

Read the DTCs.

Result Result Proceed to DTC P0087 is output A DTC P0087 and other DTCs are output B Tech Tips

If any DTCs other than P0087 are output, troubleshoot those DTCs first.

B

GO TO DTC CHART Click here

A

-

-

CHECK FUEL PRESSURE (LOW PRESSURE SIDE)

-

Check the fuel pressure Click here.

NG

CHECK FUEL PUMP OPERATION Click here

OK

-

-

CHECK MISFIRE COUNT

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Injection Way / Direct.

-

Allow the engine to idle.

-

Monitor all of the misfire count values that are displayed on the GTS: Powertrain / Engine and ECT / Data List / Misfire / Cylinder #1 Misfire count to Cylinder #6 Misfire count.

If no misfire counts occur for any of the cylinders, perform the following procedure:

-

Move the shift lever to D.

-

Monitor all of the misfire rate values that are displayed on the GTS.

Result Misfire Count Proceed to No misfire counts, or misfire counts occur randomly in all cylinders A Misfire counts occur in a particular cylinder B Tech Tips

Perform "Inspection After Repair" after replacing the fuel injector assembly (for direct injection) Click here.

-

B

REPLACE FUEL INJECTOR FOR DIRECT INJECTION Click here

A

-

-

INSPECT FUEL RELIEF VALVE

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Start the engine.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Fuel Press.

-

Record the Fuel Press value.

-

Turn the engine switch off.

-

Wait for 10 seconds.

-

Turn the engine switch on (IG) and turn the GTS ON.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Fuel Press.

-

Compare the Fuel Press value recorded with the engine running to the Fuel Press value currently shown on the GTS.

Result Inspection Result Proceed to Fuel Press value is maintained A Fuel Press value drops B

B

REPLACE FUEL RELIEF VALVE Click here

A

-

-

REPLACE FUEL PUMP ASSEMBLY (FOR HIGH PRESSURE)

-

Replace the fuel pump assembly (for high pressure) Click here.

Tech Tips

Perform "Inspection After Repair" after replacing the fuel pump assembly (for high pressure) Click here.

NEXT

-

-

CHECK WHETHER DTC OUTPUT RECURS

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG) and turn the GTS on.

-

Clear the DTCs.

-

Drive the vehicle in accordance with the driving pattern described in the Confirmation Driving Pattern.

-

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

-

Read the DTCs.

Result Result Proceed to DTC P0087 is output A DTC is not output B

B

END

A

REPLACE ECM Click here

-

-

CHECK FUEL PUMP OPERATION

-

Check the fuel pump operation Click here.

NG

REPLACE FUEL PUMP (LOW PRESSURE SIDE) Click here

OK

CHECK AND REPLACE FUEL SYSTEM (PRESSURE REGULATOR, PIPE LINE AND FILTER)

-