VEHICLE STABILITY CONTROL SYSTEM CALIBRATION

-

DESCRIPTION

-

After replacing any VSC related components or performing a front wheel alignment adjustment, clear and read the sensor calibration data and system information.

-

Follow the chart below to perform calibration.

Parts to be Replaced / Operation Necessary Operation Skid control ECU (Brake actuator assembly) Yaw rate and acceleration sensor zero point calibration and store system information Yaw rate and acceleration sensor

-

Clearing zero point calibration data and system information

-

Yaw rate and acceleration sensor zero point calibration and store system information

Front wheel alignment adjustment

-

Clearing zero point calibration data and system information

-

Yaw rate and acceleration sensor zero point calibration and store system information

-

-

PERFORM YAW RATE AND ACCELERATION SENSOR ZERO POINT CALIBRATION AND STORE SYSTEM INFORMATION (When Using the GTS)

Note

-

Stored system information cannot be overwritten unless it is cleared. Clear the stored information and then store new system information.

-

While obtaining the zero points, keep the vehicle stationary and do not vibrate, tilt, move or shake it. (Do not start the engine.)

-

Be sure to perform this procedure on a level surface with an inclination of less than 1 degree.

-

Clear the zero point calibration data and system information.

Note

Performing the following procedure will clear the zero points of the yaw rate and acceleration sensor and system information simultaneously.

-

Turn the engine switch off.

-

Check that the steering wheel is centered.

-

Check that the shift lever is in P.

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the GTS on.

-

Select the skid control ECU (brake actuator assembly) to clear the zero point calibration data using the GTS. Enter the following menus: Chassis / ABS/VSC/TRC / Utility / Reset Memory.

-

Turn the engine switch off.

Note

-

If the vehicle is driven after the zero point of the yaw rate and acceleration sensor and system information are cleared, DTCs will be stored.

-

If the engine switch is turned on (IG) for more than 15 seconds with the shift lever in P after the zero points of the yaw rate and acceleration sensor have been cleared, only the zero point of the yaw rate sensor will be stored. If the vehicle is driven under these conditions, the skid control ECU (brake actuator assembly) will store the zero point calibration for the acceleration sensor as not being completed. The skid control ECU (brake actuator assembly) will then also indicate this as a malfunction of the VSC system using the indicator lights.

-

-

-

Perform the yaw rate and acceleration sensor zero point calibration and store system information.

Note

Performing the following procedure will perform the yaw rate and acceleration sensor zero point calibration and store system information simultaneously.

-

Turn the engine switch off.

-

Check that the steering wheel is centered.

-

Check that the shift lever is in P.

Note

-

DTCs C1210 (Zero Point Calibration of Yaw Rate Sensor Undone) and C1336 (Zero Point Calibration of Acceleration Sensor Undone) will be recorded if the shift lever is not in P.

-

If a DTC is stored that indicates zero point calibration is incomplete, repeat the procedure starting at the step for clearing the zero point calibration data and system information.

-

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Turn the GTS on.

-

Switch the skid control ECU (brake actuator assembly) to Test Mode using the GTS. Enter the following menus: Chassis / ABS/VSC/TRC / Utility / Test Mode.

-

After Test Mode has been entered, keep the vehicle stationary on a level surface for 5 seconds or more.

-

Check that the slip indicator light blinks in the test mode pattern (0.125 seconds on and 0.125 seconds off).

Tech Tips

-

If the slip indicator light does not blink, perform zero point calibration again.

-

Zero point calibration is performed only once after the system enters test mode.

-

Calibration cannot be performed again until the stored data is cleared.

-

-

Turn the engine switch off and disconnect the GTS.

-

-

-

PERFORM YAW RATE AND ACCELERATION SENSOR ZERO POINT CALIBRATION AND STORE SYSTEM INFORMATION (When not Using the GTS)

Note

-

Stored system information cannot be overwritten unless it is cleared. Clear the stored information and then store new system information.

-

While obtaining the zero points, keep the vehicle stationary and do not vibrate, tilt, move or shake it. (Do not start the engine.)

-

Be sure to perform this procedure on a level surface with an inclination of less than 1 degree.

-

Clear the zero point calibration data and system information.

Note

Performing the following procedure will clear the zero points of the yaw rate and acceleration sensor and system information simultaneously.

-

Turn the engine switch off.

-

Check that the steering wheel is centered.

-

Check that the shift lever is in P.

-

Turn the engine switch on (IG).

-

The warning light and indicator light come on for 3 seconds to indicate that the initial check is completed.

-

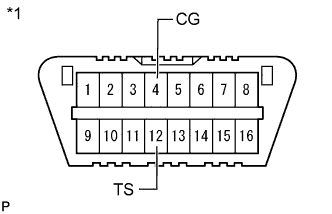

Text in Illustration *1 DLC3 Using SST, connect and disconnect terminals TS and CG of the DLC3 4 times or more within 8 seconds.

- SST

- 09843-18040

-

Check that the slip indicator lights come on.

Note

-

If the vehicle is driven after the zero point of the yaw rate and acceleration sensor and system information are cleared, DTCs will be stored.

-

If the engine switch is turned on (IG) for more than 15 seconds with the shift lever in P after the zero points of the yaw rate and acceleration sensor have been cleared, only the zero point of the yaw rate sensor will be stored. If the vehicle is driven under these conditions, the skid control ECU (brake actuator assembly) will store the zero point calibration for the acceleration sensor as not being completed. The skid control ECU (brake actuator assembly) will then also indicate this as a malfunction of the VSC system using the indicator lights.

-

-

-

Perform the yaw rate and acceleration sensor zero point calibration and store system information.

Note

Performing the following procedure will perform the yaw rate and acceleration sensor zero point calibration, and also store system information simultaneously.

-

Turn the engine switch off.

-

Check that the steering wheel is centered.

-

Check that the shift lever is in P.

Note

-

DTCs 36 (Zero Point Calibration of Yaw Rate Sensor Undone) and 98 (Zero Point Calibration of Acceleration Sensor Undone) will be recorded if the shift lever is not in P.

-

If a DTC is stored that indicates zero point calibration is incomplete, repeat the procedure starting at the step for clearing the zero point calibration data and system information.

-

-

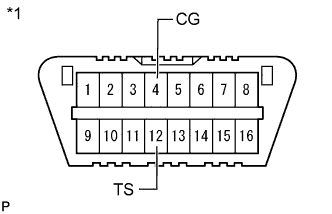

Text in Illustration *1 DLC3 Using SST, connect terminals TS and CG of the DLC3.

- SST

- 09843-18040

-

Turn the engine switch on (IG).

-

After Test Mode has been entered, keep the vehicle stationary on a level surface for 5 seconds or more.

-

Check that the slip indicator light blinks in the test mode pattern (0.125 seconds on and 0.125 seconds off).

Tech Tips

-

If the slip indicator light does not blink, perform zero point calibration again.

-

Zero point calibration is performed only once after the system enters test mode.

-

Calibration cannot be performed again until the stored data is cleared.

-

-

Turn the engine switch off and disconnect SST from the DLC3.

-

-