STARTER REASSEMBLY

Tech Tips

Use high-temperature grease to lubricate the bearings, gears and return spring when assembling the starter.

-

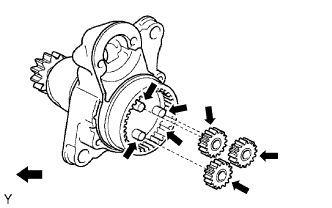

INSTALL PLANETARY GEAR

-

Apply grease to the planetary gears and pin parts of the planetary shaft.

Text in Illustration

High-temperature grease -

Install the 3 planetary gears.

-

-

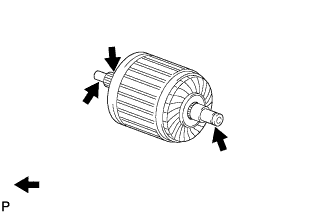

INSTALL STARTER ARMATURE ASSEMBLY

-

Apply grease to the armature shaft.

Text in Illustration

High-temperature grease -

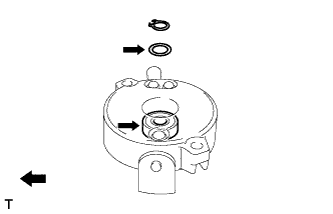

Apply high-temperature grease to the plate washer and bearing as shown in the illustration.

Text in Illustration

High-temperature grease -

Install the starter armature to the starter commutator end frame assembly.

-

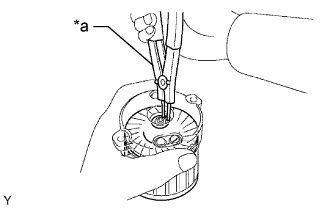

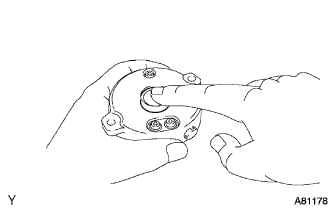

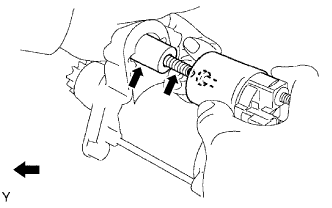

Text in Illustration *a Snap Ring Pliers Using snap ring pliers, install the plate washer and a new snap ring.

Note

-

Be sure to install the snap ring in the armature shaft groove securely.

-

Be sure to properly install the snap ring because it expands easily.

-

-

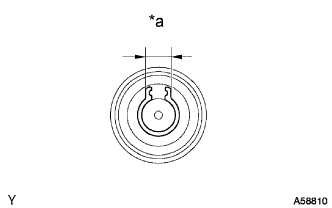

Text in Illustration *a Length Using a vernier caliper, measure the length of the snap ring.

Maximum length 5.0 mm (0.196 in.) If the length is greater than the maximum, replace it with a new snap ring.

-

-

INSTALL STARTER COMMUTATOR END FRAME COVER

-

Install the end frame cover to the starter commutator end frame assembly.

-

-

INSTALL STARTER ARMATURE PLATE

-

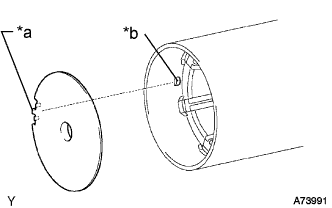

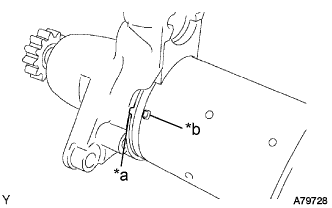

Text in Illustration *a Keyway *b Key Insert the starter armature plate to the starter yoke assembly.

-

Align the keyway of the starter armature plate with the key inside the starter yoke assembly, and install the starter armature plate.

-

-

INSTALL STARTER COMMUTATOR END FRAME ASSEMBLY

-

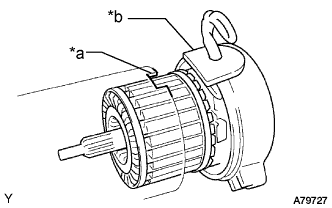

Text in Illustration *a Cutout *b Rubber Align the rubber of the starter commutator end frame assembly with the cutout of the starter yoke assembly.

-

Install the starter commutator end frame assembly to the starter yoke assembly.

Note

The magnet of the starter yoke may attract the starter armature when the starter commutator end frame is installed, causing the magnet to break.

-

-

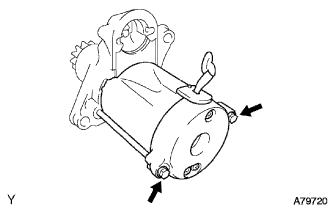

INSTALL STARTER YOKE ASSEMBLY

-

Text in Illustration *a Cutout *b Protrusion Align the protrusion of the starter yoke assembly with the cutout of the starter drive housing.

-

Install the starter yoke assembly with the 2 through-bolts.

- Torque:

- 6.0 N*m { 61 kgf*cm, 53 in.*lbf }

-

-

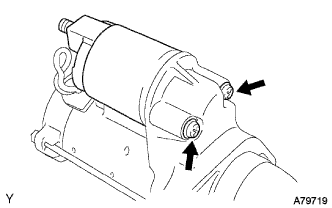

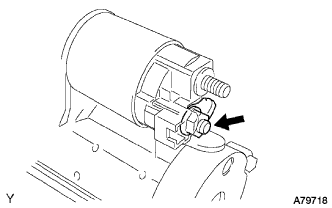

INSTALL REPAIR SERVICE STARTER KIT

-

Apply grease to the plunger and the hook.

Text in Illustration

High-temperature grease -

Hang the plunger hook of the magnetic switch on the drive lever.

-

Install the plunger and return spring.

-

Install the magnetic switch with the 2 screws.

- Torque:

- 7.5 N*m { 76 kgf*cm, 66 in.*lbf }

-

Connect the lead wire to the magnetic switch with the nut.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-