CYLINDER HEAD GASKET INSTALLATION

-

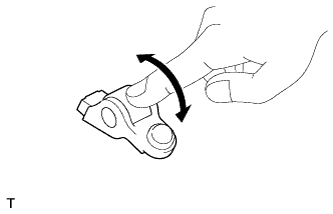

INSPECT NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

-

Turn the roller by hand to check that it turns smoothly.

If the roller does not turn smoothly, replace the No. 1 valve rocker arm sub-assembly.

-

-

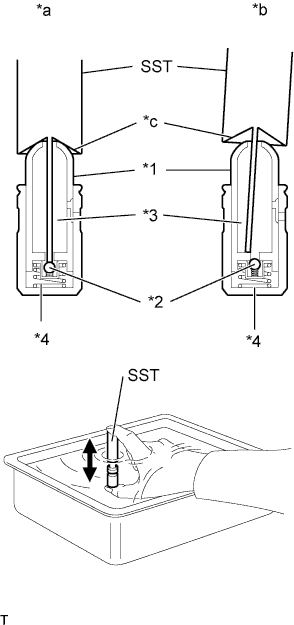

INSPECT VALVE LASH ADJUSTER ASSEMBLY

Note

-

Keep the valve lash adjuster free from dirt and foreign matter.

-

Only use clean engine oil.

-

Place the lash adjuster into a container filled with new engine oil.

-

Text in Illustration *1 Plunger *2 Check Ball *3 Low Pressure Chamber *4 High Pressure Chamber *a CORRECT *b INCORRECT *c Taper Part Insert the tip of SST into the lash adjuster plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

-

Squeeze SST and the valve lash adjuster together to move the plunger up and down 5 to 6 times.

-

Check the movement of the plunger and bleed the air.

OK Plunger moves up and down. Note

When bleeding air from the high pressure chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, air bleeding is not possible.

-

After bleeding the air, remove SST. Then try to quickly and firmly press the plunger with your fingers.

OK Plunger is very difficult to move. If the result is not as specified, replace the valve lash adjuster assembly.

-

-

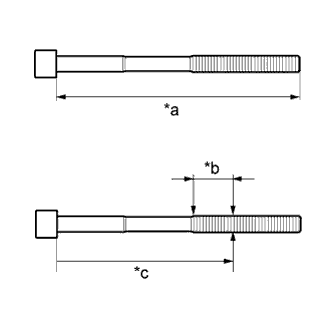

INSPECT CYLINDER HEAD SET BOLT

-

Text in Illustration *a Measurement Length *b Measurement Area *c Distance Using a vernier caliper, measure the length of the cylinder head set bolt from the seat to the end.

Standard length 146.8 to 148.2 mm (5.78 to 5.83 in.) Maximum length 149.2 mm (5.87 in.) Tech Tips

-

If the length is greater than the maximum, replace the bolt with a new one. Failure to do so may lead to engine damage.

-

If there is any thread deformation, replace the bolt with a new one.

-

-

Using a vernier caliper, measure the diameter of the threaded portion of the bolt at its thinnest point.

Tech Tips

Use a straightedge to determine the thinnest point of the threaded portion of the bolt.

Measurement point 115 mm (4.53 in.) Standard diameter 9.77 to 9.96 mm (0.385 to 0.392 in.) Minimum diameter 9.4 mm (0.370 in.) Tech Tips

-

If the diameter is less than the minimum, replace the cylinder head set bolt with a new one. Failure to do so may lead to engine damage.

-

If there is any thread deformation, replace the cylinder head set bolt with a new one.

Tech Tips

If a visual check reveals no excessively thin areas, check the center of the bolt (refer to illustration) and find the area that has the smallest diameter.

-

-

-

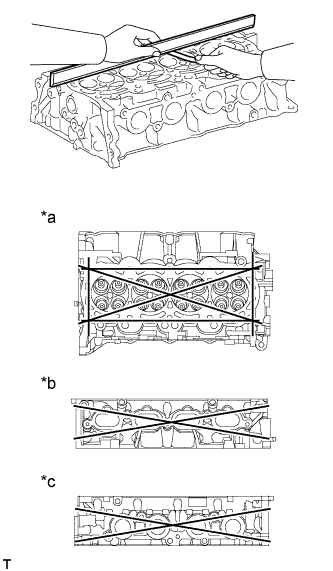

INSPECT CYLINDER HEAD

-

Text in Illustration *a Cylinder Head Lower Side: *b Intake Manifold Side: *c Exhaust Manifold Side: Using a precision straightedge and feeler gauge, measure the warpage of the contact surfaces where the cylinder head contacts the cylinder block and manifold.

Maximum Warpage Item Specified Condition Cylinder block side 0.05 mm (0.00197 in.) Intake manifold side 0.10 mm (0.00394 in.) Exhaust manifold side 0.10 mm (0.00394 in.) If the warpage is more than the maximum, replace the cylinder head.

-

-

INSTALL CYLINDER HEAD GASKET

-

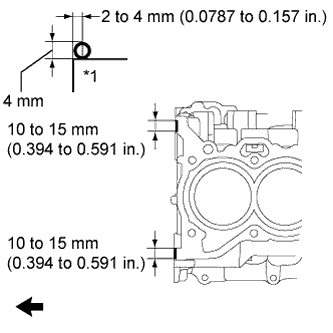

Text in Illustration *1 Cylinder Block

Engine Front Apply seal packing (diameter 4.0 mm (0.157 in.)) to the cylinder block as shown in the illustration.

Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note

Remove any oil from the cylinder block.

-

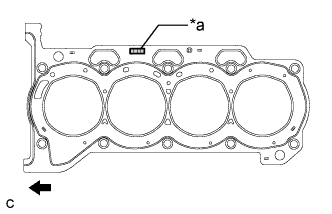

Text in Illustration *a Lot No.

Engine Front Place a new cylinder head gasket on the cylinder block with the Lot No. stamp facing upward.

Note

Install the cylinder head gasket within 3 minutes of applying seal packing.

-

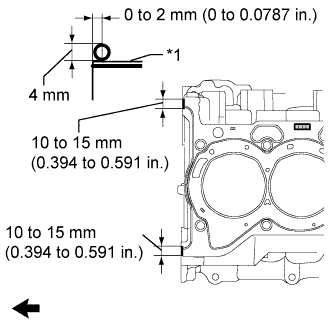

Text in Illustration *1 Cylinder Head Gasket

Engine Front Apply seal packing (diameter 4.0 mm (0.157 in.)) to the new cylinder head gasket as shown in the illustration.

Seal packing Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent Note

-

Remove any oil from the cylinder head gasket and cylinder head.

-

Install the cylinder head gasket within 3 minutes and tighten the bolts within 15 minutes of applying seal packing.

-

-

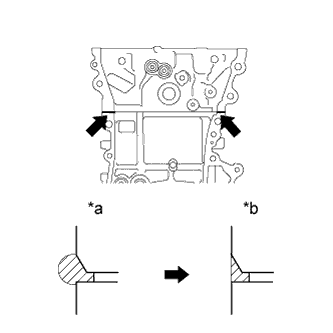

Text in Illustration *a Before wiping off *b After wiping off After tightening the cylinder head bolts, wipe off any seal packing material that seeped out from the contact surfaces between the cylinder head and cylinder block.

-

-

INSTALL CYLINDER HEAD SUB-ASSEMBLY

Tech Tips

The cylinder head bolts are tightened in 3 progressive steps.

-

Place the cylinder head on the cylinder block.

Note

-

Make sure that no oil is on the mounting surface of the cylinder head.

-

Place the cylinder head on the cylinder block gently in order not to damage the gasket with the bottom part of the head.

-

-

Install the plate washers to the cylinder head bolts.

-

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

-

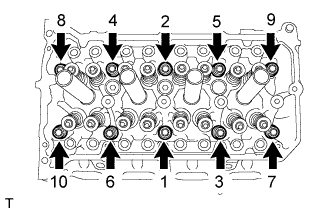

Step 1:

-

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 10 cylinder head bolts in several steps, in the sequence shown in the illustration.

- Torque:

- 49 N*m { 500 kgf*cm, 36 ft.*lbf }

Note

Do not drop the plate washers into the cylinder head.

-

-

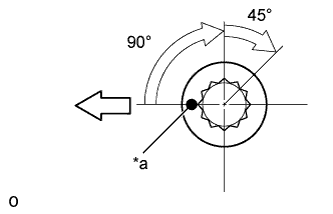

Text in Illustration *a Paint Mark

Engine Front Step 2:

-

Mark each cylinder head bolt head with paint as shown in the illustration.

-

Tighten the cylinder head bolts 90° in the sequence shown in step 1.

-

-

Step 3:

-

Tighten the cylinder head bolts another 45° in the sequence shown in step 1.

-

-

Check that the paint mark is now at a 135° angle to the front.

-

-

INSTALL VALVE STEM CAP

-

Apply a light coat of engine oil to the valve stem ends.

-

Install the 16 valve stem caps to the cylinder head.

Note

Do not drop the valve stem caps into the cylinder head.

-

-

INSTALL VALVE LASH ADJUSTER ASSEMBLY

-

Inspect each valve lash adjuster before installing it Click here.

-

Install the 16 valve lash adjusters to the cylinder head.

Note

Install the valve lash adjuster to the same place it was removed from.

-

-

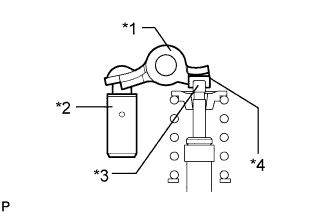

INSTALL NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY

-

Text in Illustration *1 Valve Rocker Arm *2 Valve Lash Adjuster *3 Valve Stem *4 Valve Stem Cap Apply engine oil to the valve lash adjuster tips and valve stem cap ends.

-

Make sure that the No. 1 valve rocker arms are installed as shown in the illustration.

-

-

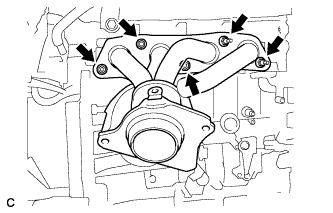

INSTALL EXHAUST MANIFOLD

-

Install a new gasket and the exhaust manifold with the 5 nuts.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

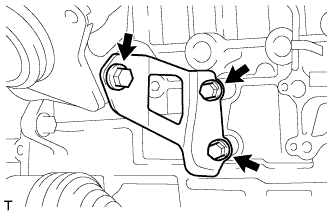

INSTALL MANIFOLD STAY

-

Install the manifold stay with the 3 bolts.

- Torque:

- 43 N*m { 438 kgf*cm, 32 ft.*lbf }

-

-

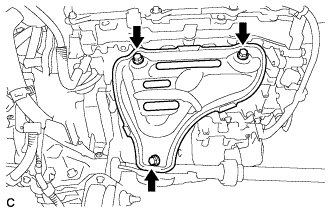

INSTALL NO. 1 EXHAUST MANIFOLD HEAT INSULATOR

-

Install the No. 1 exhaust manifold heat insulator with the 3 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

-

INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY