GENERATOR CABLE INSTALLATION

-

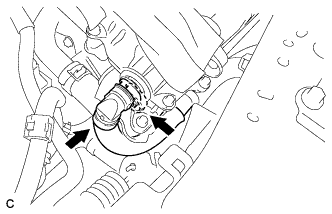

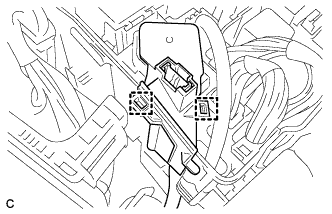

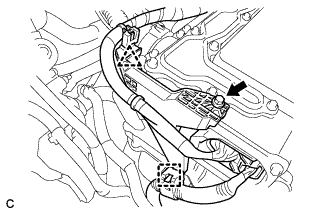

INSTALL GENERATOR CABLE

Note

Wear insulated gloves.

-

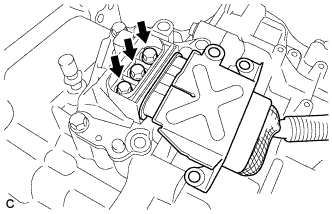

Install the generator cable to the hybrid transaxle assembly with the 3 bolts.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

Note

Keep the sealing surface of the generator cable and the connector terminal joint free of foreign matter.

-

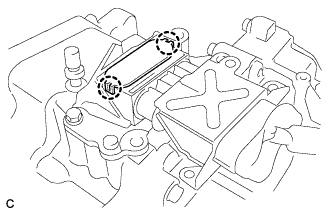

Engage the 2 claws to install a new terminal cap.

Note

When installing the terminal cap to the generator cable terminal block, keep the sealing surface free of foreign matter.

-

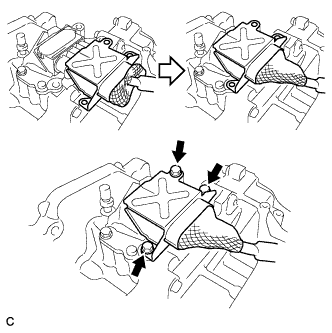

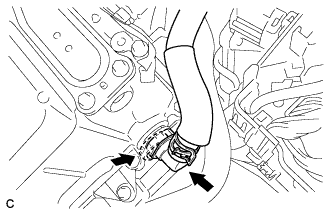

Place the generator cable connector shell in position and install it with the 3 bolts.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

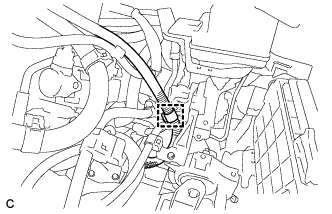

Connect the generator cable clamp to the motor cable bracket.

-

-

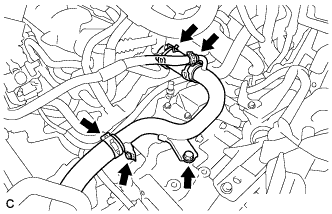

INSTALL RADIATOR PIPE

-

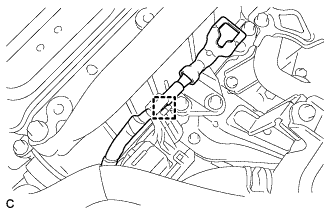

Install the radiator pipe with the 2 bolts.

- Torque:

- 19 N*m { 194 kgf*cm, 14 ft.*lbf }

-

Connect the No. 3 radiator hose, No. 4 water by-pass hose and No. 1 radiator hose with the clamps.

-

-

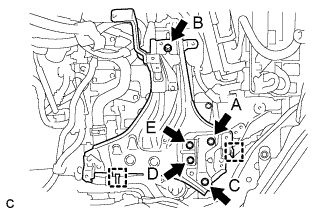

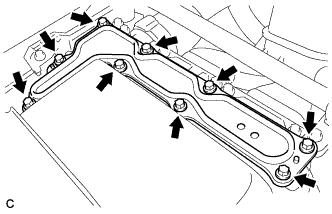

INSTALL INVERTER TRAY BRACKET

-

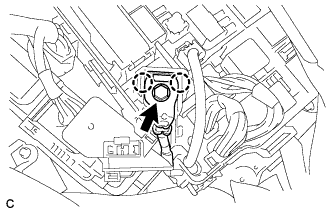

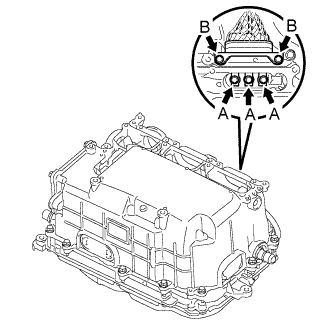

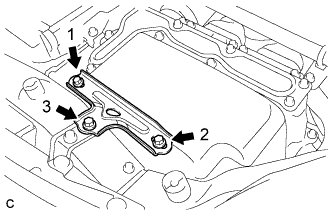

Position the inverter tray bracket as shown in the illustration.

-

Temporarily install bolt B to the inverter tray bracket.

-

Tighten the 5 bolts to the inverter tray bracket in the order the bolt A, bolt C, bolt D, bolt E and bolt B.

- Torque:

- 18 N*m { 184 kgf*cm, 13 ft.*lbf }

-

Connect the 2 clamps to the inverter tray bracket.

-

-

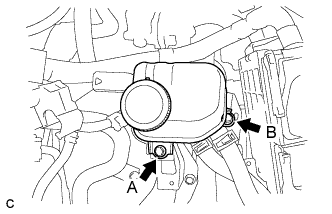

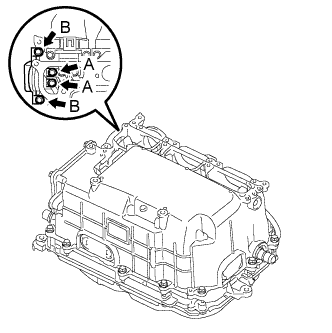

INSTALL INVERTER RESERVE TANK ASSEMBLY

-

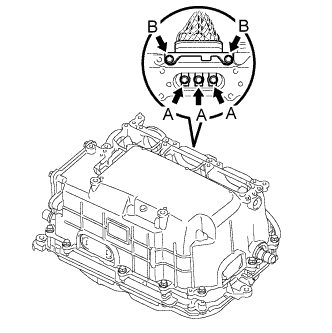

Temporarily install bolt A to the inverter reserve tank assembly.

-

Tighten the 2 bolts to the inverter reserve tank assembly in the order the bolt B and bolt A.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

-

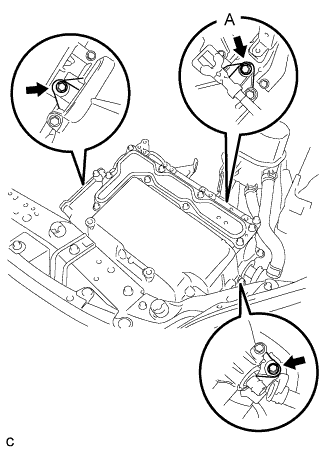

INSTALL INVERTER WITH CONVERTER ASSEMBLY

CAUTION:

Wear insulating gloves.

-

Temporarily install the inverter with converter assembly with the 3 bolts.

Note

-

Since the inverter with converter assembly is very heavy, 2 people are needed to install the inverter with converter assembly. When installing the inverter with converter assembly, do not damage the parts around it.

-

To prevent damage, do not hold the inverter with converter assembly by the connectors.

-

To prevent damage due to static electricity, do not touch the terminals of the disconnected connectors.

-

-

Tighten the bolt A.

- Torque:

- 12 N*m { 122 kgf*cm, 8 ft.*lbf }

-

Tighten the 2 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 8 ft.*lbf }

-

-

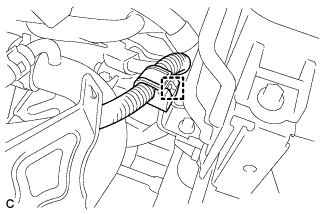

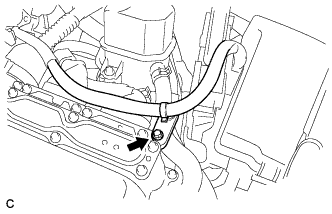

CONNECT WATER HOSE

-

Connect the water hose to the inverter with converter assembly and lock the hose with the retainer.

Note

-

Insert the retainer until a click sound is heard.

-

Pull on the hose to confirm that the hose is securely connected.

-

If there is foreign matter on the union or the O-ring, clean it with water and finger scouring.

-

-

Connect the water hose to the inverter with converter assembly and lock the hose with the retainer.

Note

-

Insert the retainer until a click sound is heard.

-

Pull on the hose to confirm that the hose is securely connected.

-

If there is foreign matter on the union or the O-ring, clean it with water and finger scouring.

-

-

-

CONNECT NO. 2 ENGINE ROOM WIRE

-

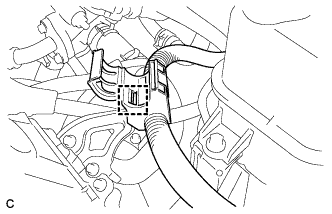

Disconnect the No. 2 engine room wire from the protector.

-

Connect the No. 2 engine room wire with the bolt and 2 claws.

- Torque:

- 8.3 N*m { 85 kgf*cm, 73 in.*lbf }

Note

Pass the No. 2 engine room wire under the two cooling hoses that pass beside the inverter.

-

Install the No. 1 relay block cover and 2 clamps.

-

Install the relay block cover.

-

-

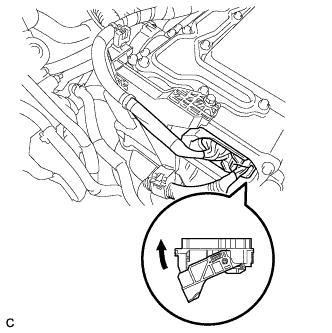

REMOVE INVERTER TERMINAL COVER

CAUTION:

Wear insulating gloves.

-

Remove the 9 bolts and inverter terminal cover.

Note

Make sure to pull the inverter terminal cover straight up, as a connector is connected to the bottom of the cover.

-

-

CONNECT NO. 2 ENGINE WIRE

CAUTION:

Wear insulating gloves.

Note

Do not allow any foreign objects or water to enter the inverter with converter assembly.

-

Connect the No. 2 engine wire (high voltage cables of the air conditioning) with the 4 bolts to the inverter with converter assembly.

- Torque:

- Bolt A

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

- Bolt B

- 9.2 N*m { 94 kgf*cm, 81 in.*lbf }

Note

Be sure to use a torque wrench to tighten the bolts.

-

Connect the harness clamp.

-

-

CONNECT HIGH VOLTAGE CABLE OF FRONT TRANSAXLE

CAUTION:

Wear insulating gloves.

Note

Do not allow any foreign objects or water to enter the inverter with converter assembly.

-

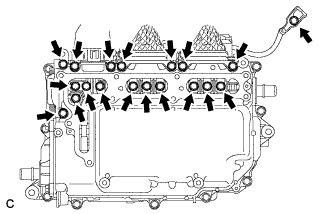

Connect the high voltage cable of the motor (MG2) with 5 bolts to the inverter with converter assembly.

- Torque:

- Bolt A

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

- Bolt B

- 9.2 N*m { 94 kgf*cm, 81 in.*lbf }

Note

Be sure to use a torque wrench to tighten the bolts.

-

Connect the harness clamp.

-

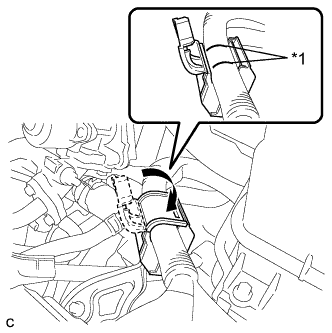

Connect the high voltage cable of the generator (MG1) with the 5 bolts to the inverter with converter assembly.

- Torque:

- Bolt A

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

- Bolt B

- 9.2 N*m { 94 kgf*cm, 81 in.*lbf }

Note

Be sure to use a torque wrench to tighten the bolts.

-

Text in Illustration *1 Align Mark Install the cable and cover.

Note

Close the cover so that the matchmarks are not visible.

-

-

CONNECT FRAME WIRE

CAUTION:

Wear insulating gloves.

Note

-

Make sure that the interlock is fully engaged.

-

Do not allow any foreign objects or water to enter the inverter with converter assembly.

-

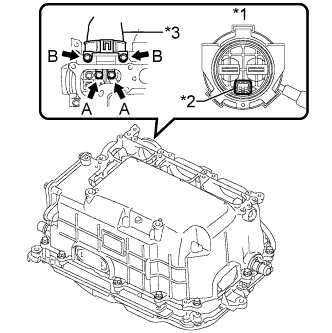

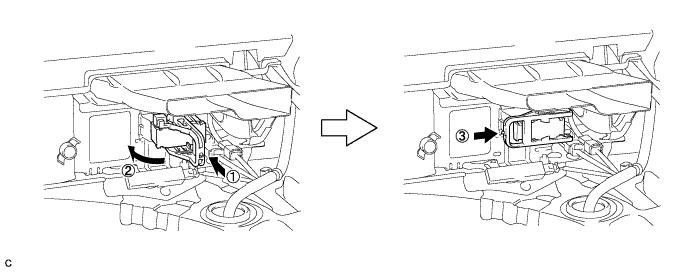

Text in Illustration *1 Front view of frame wire connector *2 Interlock *3 High voltage cables of the hybrid battery Connect the frame wire (high voltage cables of the hybrid battery) with the 4 bolts to the inverter with converter assembly.

- Torque:

- Bolt A

- 8.0 N*m { 82 kgf*cm, 71 in.*lbf }

- Bolt B

- 9.2 N*m { 94 kgf*cm, 81 in.*lbf }

Note

-

Be sure to use a torque wrench to tighten the bolts.

-

Make sure that the interlock is fully engaged.

-

Connect the harness clamp.

-

-

CHECK HIGH VOLTAGE CABLE CONNECTION

CAUTION:

Wear insulating gloves.

Note

Do not allow any foreign objects or water to enter the inverter with converter assembly.

-

Check that each connector and terminal is firmly installed.

Note

Make sure that the bolts are fully tightened.

-

-

INSTALL INVERTER TERMINAL COVER

CAUTION:

Wear insulating gloves.

Note

-

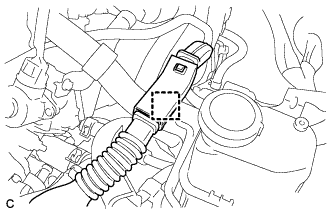

Make sure that the interlock is fully engaged.

-

Do not allow any foreign objects or water to enter the inverter with converter assembly.

-

Text in Illustration *1 Interlock Install the inverter terminal cover with the 9 bolts to the inverter with converter assembly.

- Torque:

- 11 N*m { 112 kgf*cm, 8 ft.*lbf }

-

-

INSTALL ENGINE ROOM MAIN WIRE

Note

-

Make sure that the connectors are fully engaged.

-

Do not allow any foreign objects or water to enter the inverter with converter assembly.

-

Install the bolt, clamp and clip, and connect the engine room main ware.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

Install the bolt.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

Connect the engine wire to the engine room main wire.

-

Connect the connector to the inverter with converter assembly and lock the connector with the lock lever.

-

-

INSTALL NO. 1 INVERTER BRACKET

-

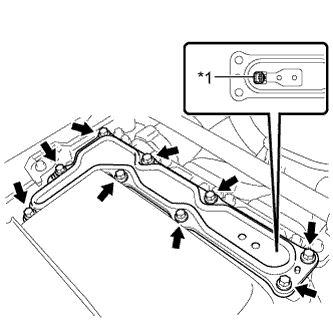

Temporarily install the No. 1 inverter bracket with the 3 bolts.

-

Tighten the 3 bolts in the order shown in the illustration.

- Torque:

- 14 N*m { 140 kgf*cm, 10 ft.*lbf }

-

-

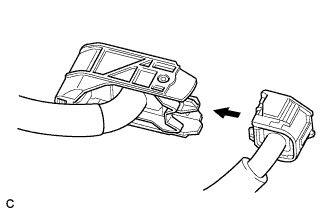

INSTALL SERVICE PLUG GRIP

CAUTION:

Wear insulating gloves.

Note

Before connecting the service plug, check that no parts and tools remain and that the high voltage terminals and connectors are connected securely.

-

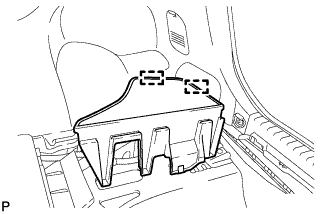

Wear insulated gloves and install the service plug grip in the order shown in the illustration.

-

Rotate the handle of the service plug grip 90° toward the battery and slide it in the direction shown by the arrow until a click sound is heard.

-

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

INSTALL REAR NO. 3 FLOOR BOARD

-

Engage the 2 guides to install the rear No. 3 floor board.

-

-

INSTALL REAR DECK FLOOR BOX

-

Install the rear deck floor box.

-

-

INSTALL REAR NO. 2 FLOOR BOARD

-

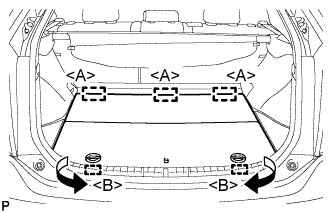

Engage the 3 guides <A>.

-

Engage the 2 guides <B> and install the rear No. 2 floor board as shown in the illustration.

-

-

ADD COOLANT (for Inverter)

Note

-

Do not reuse the drained coolant because it may contain foreign objects.

-

If the vehicle is driven with air in the inverter cooling system, damage may occur and the following DTCs may be set.

DTC Code Detection Item P0A01-726 Motor Electronics Coolant Temperature Sensor Circuit Range / Performance P0A04-725 Motor Electronics Coolant Temperature Sensor Circuit Intermittent P0A08-264 DC / DC Converter Status Circuit P0A78-284 Drive Motor "A" Inverter Performance P0A78-286 Drive Motor "A" Inverter Performance P0A7A-322 Generator Inverter Performance P0A7A-324 Generator Inverter Performance P0A93-346 Inverter Cooling System Performance P0A94-553 DC / DC Converter Performance P0A94-557 DC / DC Converter Performance P0AEE-277 Motor Inverter Temperature Sensor "A" Circuit Range / Performance P0AF1-276 Drive Motor Inverter Temperature Sensor "A" Circuit Intermittent / Erratic P0BCD-315 Generator Inverter Temperature Sensor Circuit Range / Performance P0BD0-314 Generator Inverter Temperature Sensor Circuit Intermittent / Erratic P0C39-626 DC / DC Converter Temperature Sensor "A" Range / Performance P0C3C-625 DC / DC Converter Temperature Sensor "A" Intermittent / Erratic P0C3E-628 DC / DC Converter Temperature Sensor "B" Range / Performance P0C41-627 DC / DC Converter Temperature Sensor "B" Intermittent / Erratic P0C73-776 Motor Electronics Coolant Pump "A" Control Performance

-

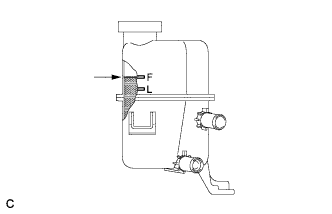

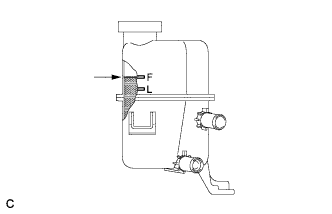

Slowly pour coolant into the reserve tank until it reaches the F line.

Coolant quantity 2.1 liters (2.2 US qts, 1.8 Imp. qts.) -

When using the intelligent tester:

-

Connect the intelligent tester to the DLC3.

-

Turn the power switch on (IG).

-

On the intelligent tester, enter the following menus: Powertrain / Hybrid Control / Active Test / Activate the Water Pump.

-

Keep the coolant at the F line in the reserve tank to compensate for the drop in coolant level when the air bleeds.

Standard Air bleeding from the inverter cooling system is completed when the noise made by the water pump becomes smaller and the circulation of coolant in the reserve tank improves. Tech Tips

Loud noise made by the water pump and poor circulation of coolant in the reserve tank indicates that there is air in the cooling system.

-

-

When not using the intelligent tester:

-

Turn the power switch on (READY). [*1]

-

Turn the power switch off and add coolant to the F line because the coolant level drops as the air bleeds. [*2]

Note

-

Be sure to turn the power switch off before adding SLLC.

-

Do not work on the components in the engine compartment while the vehicle is in the READY-on state because the engine is in intermittent operation.

-

-

Repeat steps [*1] and [*2] until air bleeding from the cooling system is completed.

Standard Air bleeding from the inverter cooling system is completed when the noise made by the water pump becomes smaller and the circulation of coolant in the reserve tank improves. Tech Tips

Loud noise made by the water pump and poor circulation of coolant in the reserve tank indicates that there is air in the cooling system.

-

-

After the air is completely bled from the cooling system, tighten the reserve tank cap.

-

Add coolant to the F line of the reserve tank.

-

-

ADD COOLANT (for Engine)

-

Tighten the radiator drain cock plug.

-

Remove the reservoir tank cap.

-

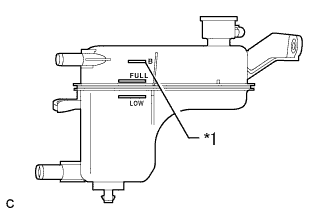

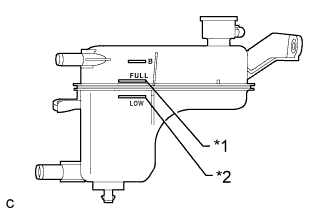

Text in Illustration *1 B Line Add coolant to B line of the reservoir tank.

Standard Capacity Item Capacity Engine coolant w/ Exhaust Heat Recirculation System:

7.2 liters (7.6 US qts, 6.3 lmp. qts)

w/o Exhaust Heat Recirculation System:

6.5 liters (6.8 US qts, 5.7 lmp. qts)

Tech Tips

TOYOTA vehicles are filled with TOYOTA SLLC at the factory. In order to avoid damage to the engine cooling system and other technical problems, only use TOYOTA SLLC or similar high quality ethylene glycol based non-silicate, non-amine, non-nitrite, non-borate coolant with long-life hybrid organic acid technology (coolant with long-life hybrid organic acid technology is a combination of low phosphates and organic acids).

Note

Never use water as a substitute for engine coolant.

-

Squeeze the inlet and outlet radiator hoses several times by hand, and then check the level of the coolant.

If the coolant level is low, add coolant.

-

Install the reservoir tank cap.

-

Put the engine in inspection mode Click here.

-

Bleed air from the cooling system.

Note

-

Before starting the engine, turn the A/C switch off.

-

Adjust the heater control to the maximum hot setting.

-

Adjust the blower speed to low setting.

-

Warm up the engine until the thermostat opens. While the thermostat is open, allow the coolant to circulate for several minutes.

Tech Tips

The thermostat opening timing can be confirmed by squeezing the inlet radiator hose by hand, and sensing vibrations when the engine coolant starts to flow inside the hose.

CAUTION:

When squeezing the radiator hose:

-

Wear protective gloves.

-

Be careful as the radiator hoses are hot.

-

Keep your hands away from the radiator fan.

-

-

Squeeze the inlet and outlet radiator hoses several times by hand to bleed air from the system.

CAUTION:

When squeezing the radiator hose:

-

Wear protective gloves.

-

Be careful as the radiator hoses are hot.

-

Keep your hands away from the radiator fan.

-

-

-

Text in Illustration *1 Full Line *2 Low Line After the engine has cooled down, check that the coolant level is between full and low.

If the coolant level is low, add coolant to the full line on the reservoir tank.

-

-

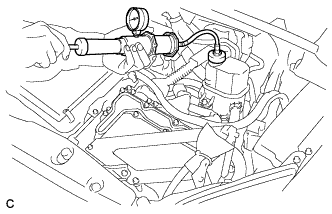

INSPECT FOR COOLANT LEAK (for Inverter)

-

Remove the reserve tank cap.

CAUTION:

To avoid the danger of being burned, do not remove the reserve tank cap while the coolant for the inverter is still hot.

-

Install the radiator cap tester.

-

Pump the radiator cap tester to 122 kPa (1.2 kgf/ cm2, 17.7 psi), and then check that the pressure does not drop.

Tech Tips

If the pressure drops, check the hoses, radiator, water pump, inverter with converter, and hybrid vehicle transaxle assembly for leaks.

-

Reinstall the reserve tank cap.

-

-

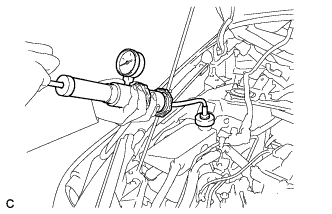

INSPECT FOR COOLANT LEAK (for Engine)

CAUTION:

Do not remove the reservoir tank cap while the engine and radiator are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

Note

Before performing each inspection, turn the A/C switch off.

-

Remove the reservoir tank cap.

-

Fill the radiator and reservoir with coolant, and then attach a radiator cap tester.

-

Put the engine in inspection mode Click here.

-

Warm up the engine.

-

Using the reservoir cap tester, increase the pressure inside the radiator to 108 kPa (1.1 kgf/cm2, 16 psi), and check that the pressure does not drop. If the pressure drops, check the hoses, radiator, front exhaust pipe assembly and the heater hose around and engine water pump assembly for leaks. If no external leaks are found, check the heater core, cylinder block and cylinder head.

-

Remove the radiator cap tester.

-

Install the reservoir tank cap.

-

-

INSTALL NO. 1 ENGINE UNDER COVER

-

INSTALL FRONT LOWER BUMPER ABSORBER (w/ Cover)

-

INSTALL FRONT SPOILER COVER (w/ Front Spoiler)

-

INSTALL RADIATOR SUPPORT OPENING COVER

-

Engage the 2 claws and install the radiator support opening cover.

-

Install the 3 clips.

-