REFRIGERANT REPLACEMENT

-

RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

-

Start the engine.

-

Turn the A/C switch on.

-

Operate the cooler compressor while the engine speed is approximately 1000 rpm for 5 to 6 minutes to circulate the refrigerant and collect the compressor oil remaining in each component into the cooler compressor.

-

Stop the engine.

-

Recover the refrigerant from the A/C system using a refrigerant recovery unit.

-

-

CHARGE REFRIGERANT

- SST

- 09985-20010 ( 09985-02130, 09985-02150, 09985-02090, 09985-02110, 09985-02010, 09985-02050, 09985-02060, 09985-02070 )

-

Perform vacuum purging using a vacuum pump.

-

Charge refrigerant HFC-134a (R134a).

Standard 440 +/-30 g (15.5 +/-1.1 oz)

Note

-

Do not operate the cooler compressor before charging refrigerant as the cooler compressor will not work properly without any refrigerant, and will overheat.

-

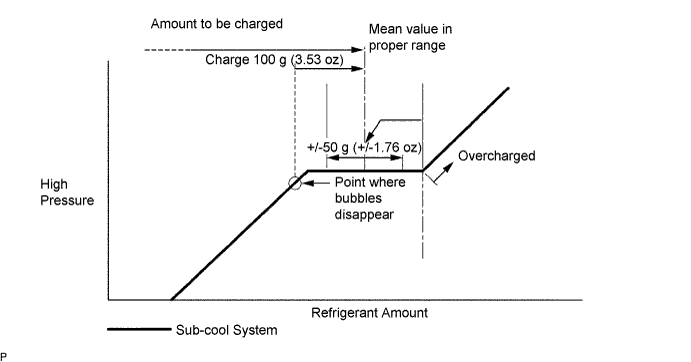

Approximately 200 g (7.05 oz) of refrigerant may need to be charged after bubbles disappear. The refrigerant amount should be checked by measuring its quantity, and not with the sight glass.

-

-

WARM UP ENGINE

-

Warm up the engine at less than 1850 rpm for 2 minutes or more after charging the refrigerant.

Note

Be sure to warm up the compressor when turning the A/C switch on after removing and installing the cooler refrigerant lines (including the compressor) to prevent damage to the compressor.

-

-

CHECK FOR REFRIGERANT GAS LEAK

-

After recharging the refrigerant gas, check for refrigerant gas leakage using a halogen leak detector.

-

Perform the operation observing the following instructions:

-

Stop the engine.

-

Secure good ventilation (the halogen leak detector may react to volatile gases other than refrigerant, such as evaporated gasoline or exhaust gas).

-

Repeat the test 2 or 3 times.

-

Make sure that some refrigerant remains in the refrigeration system.

Tech Tips

When the compressor is off: approximately 392 to 588 kPa (4.0 to 6.0 kgf/cm2, 57 to 85 psi).

-

-

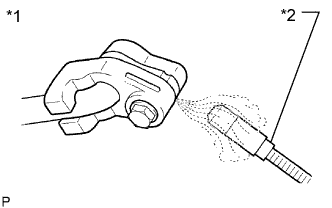

Text in Illustration *1 Check for Leakage *2 Halogen Leak Detector Using a halogen leak detector, check the refrigerant line for leakage.

-

If a gas leak is not detected from the drain hose, remove the blower motor control (blower resistor) from the cooling unit. Insert the halogen leak detector sensor into the unit and check for gas leakage.

-

Disconnect the pressure switch connector and wait for approximately 20 minutes. Bring the halogen leak detector close to the pressure switch and check for gas leakage.

-