AUTOMATIC TRANSAXLE SYSTEM (for 3ZR-FE), Diagnostic DTC:P0717

DESCRIPTION

This sensor detects the rotation speed of the turbine, which shows the input revolution of the transaxle. By comparing the input speed signal (NT) with the counter gear speed sensor signal (NC), the ECM detects the shift timing of the gears and controls the engine torque and hydraulic pressure according to various conditions. As a result, smooth gear shifting is achieved.

| DTC Code | DTC Detection Condition | Trouble Area |

|---|---|---|

| P0717 | The ECM detects conditions (a), (b) and (c) continuously for 5 seconds or more (1 trip detection logic): (a) Vehicle speed: 50 km/h (31 mph) or more. (b) Park/neutral position switch: NSW and R are OFF. (c) Speed sensor NT: Less than 300 rpm. |

|

MONITOR DESCRIPTION

This DTC indicates that a pulse is not output from the speed sensor NT (input speed sensor) or is output only a little. The NT terminal of the ECM detects the pulse signal from the speed sensor (NT) (input RPM). The ECM compares the output of the input speed sensor (NT) with the output of the intermediate shaft speed sensor (NC) and outputs a gearshift signal based on the results.

While the vehicle is operating in 2nd, 3rd or 4th gear with the shift lever in D, if the input shaft revolution is less than 300 rpm*1 and the output shaft revolution is 1000 rpm or more*2, the ECM detects the trouble, illuminates the MIL and stores the DTC.

Tech Tips

*1: A pulse is not output or is irregularly output.

*2: The vehicle speed is approximately 50 km/h (31 mph) or more.

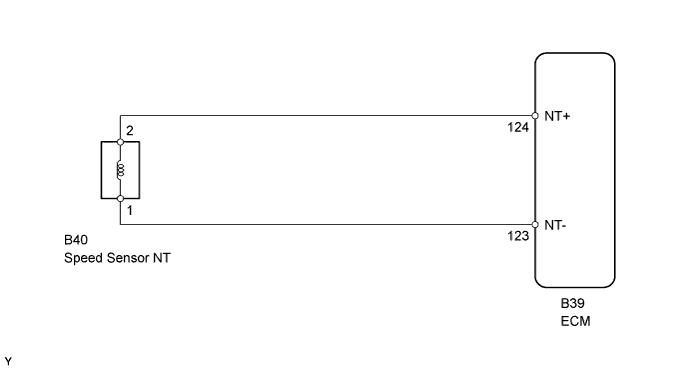

WIRING DIAGRAM

INSPECTION PROCEDURE

-

DATA LIST

Tech Tips

Using the intelligent tester to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

Note

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

-

Warm up the engine.

-

Turn the ignition switch off.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List.

-

According to the display on the tester, read the Data List.

Engine and ECT Tester Display Measurement Item/Range Normal Condition Diagnostic Note SPD (NT) Input turbine speed/

Min.: 0 rpm

Max.: 12750 rpm

-

Lock-up ON (after warming up engine):

Input turbine speed (NT) equal to engine speed

-

Lock-up OFF (idling with shift lever in N):

Input turbine speed (NT) nearly equal to engine speed

Data is displayed in increments of 50 rpm. Tech Tips

-

SPD (NT) is always 0 rpm while driving:

Open or short in the sensor or circuit.

-

SPD (NT) is always more than 0 rpm and less than 300 rpm while driving the vehicle at 50 km/h (31 mph) or more:

Sensor trouble, improper installation, or intermittent connection trouble in the circuit.

-

-

PROCEDURE

-

INSPECT SPEED SENSOR NT (INSTALLATION)

-

Check the speed sensor NT installation.

OK Installation bolt is tightened properly and there is no clearance between the sensor and transaxle case.

NG

SECURELY INSTALL OR REPLACE SPEED SENSOR NT

OK

-

-

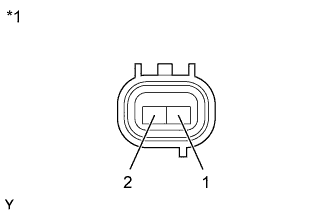

INSPECT SPEED SENSOR NT

-

Text in Illustration *1 Component without harness connected

(Speed Sensor NT)

Disconnect the B40 speed sensor NT connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 560 to 680 Ω

NG

REPLACE SPEED SENSOR NT Click here

OK

-

-

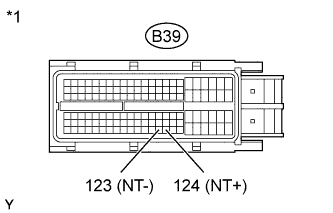

CHECK HARNESS AND CONNECTOR (SPEED SENSOR NT - ECM)

-

Text in Illustration *1 Front view of wire harness connector

(to ECM)

Disconnect the B39 ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition B39-124 (NT+) - B39-123 (NT-) 20°C (68°F) 560 to 680 Ω B39-124 (NT+) - Body ground Always 10 kΩ or higher B39-123 (NT-) - Body ground Always 10 kΩ or higher

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

REPLACE ECM Click here

-