SFI SYSTEM FREEZE FRAME DATA

-

DESCRIPTION

-

The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was moving or stationary, whether the air fuel ratio was lean or rich, as well as the other data recorded at the time of a malfunction.

Tech Tips

If it is impossible to duplicate the problem even though a DTC is stored, confirm the freeze frame data.

-

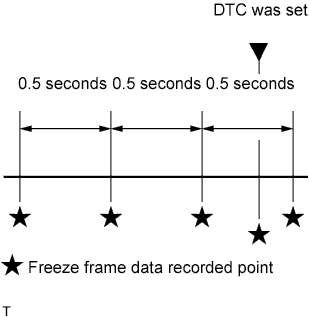

The ECM records engine conditions in the form of freeze frame data every 0.5 seconds. Using an intelligent tester, 5 separate sets of freeze frame data can be checked.

-

3 data sets before the DTC was set.

-

1 data set when the DTC was set.

-

1 data set after the DTC was set.

-

These data sets can be used to simulate the condition of the vehicle around the time of the occurrence of the malfunction. The data may assist in identifying the cause of the malfunction, and in judging whether it was temporary or not.

-

-

PENDING FREEZE FRAME DATA

Tech Tips

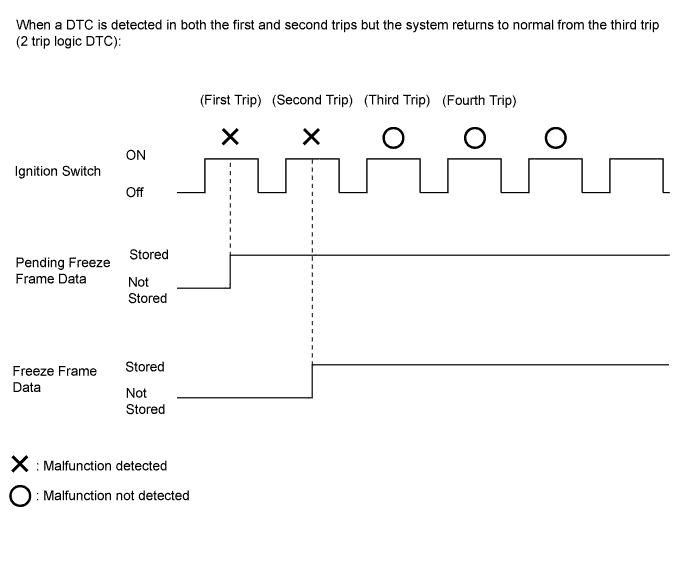

Pending freeze frame data is stored when a 2 trip DTC is first detected during the first trip.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Select a DTC in order to display its pending freeze frame data.

Tech Tips

-

Pending freeze frame data is cleared when any of the following occurs.

-

The DTCs are cleared using the tester.

-

The cable is disconnected from the negative (-) battery terminal.

-

40 trips with the engine fully warmed up have been performed after returning to normal. (Pending freeze frame data will not be cleared by only returning the system to normal.)

-

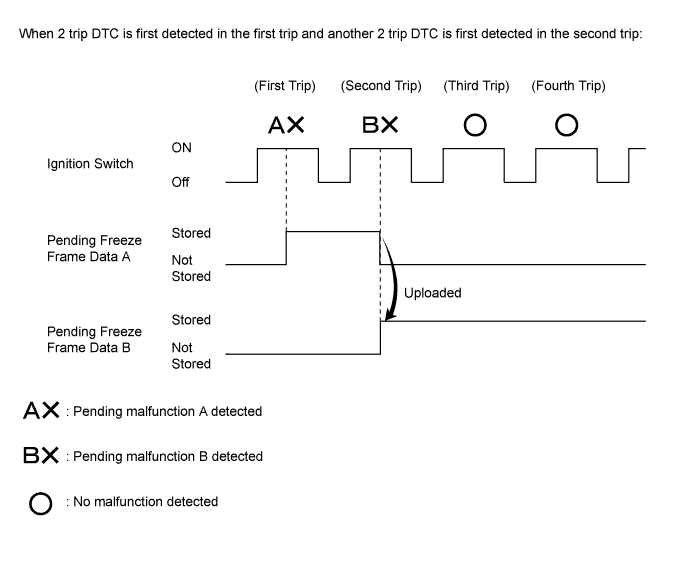

With previous pending freeze frame data stored, if pending freeze frame data is newly stored when a 2 trip DTC is detected in the first trip, the old freeze frame data will be replaced with the new data of the newly detected DTC in the next trip.

-

-

-

LIST OF FREEZE FRAME DATA

Tester Display Measurement Item Diagnostic Note Vehicle Speed Vehicle speed The speed indicated on the speedometer. Engine Speed Engine speed - Calculate Load Calculated load The load calculated by the ECM. Vehicle Load Vehicle load The load percentage in terms of the maximum intake air flow amount. MAF Air flow rate from Mass Air Flow (MAF) meter If the value is approximately 0.0 gm/sec:

-

The Mass Air Flow (MAF) meter power source circuit is open.

-

The VG circuit is open or shorted.

If the value is 160.0 gm/sec or more:

-

The E2G circuit is open.

Atmosphere Pressure Atmospheric pressure - MAP Intake manifold pressure - Coolant Temp Engine coolant temperature

-

If the value is -40°C (-40°F), the sensor circuit is open.

-

If the value is 140°C (284°F), the sensor circuit is shorted.

Intake Air Intake air temperature

-

If the value is -40°C (-40°F), the sensor circuit is open.

-

If the value is 140°C (284°F), the sensor circuit is shorted.

Engine Run Time Accumulated engine running time - Initial Engine Coolant Temp Engine coolant temperature at engine start - Initial Intake Air Temp Initial intake air temperature - Battery Voltage Battery voltage - Accel Sens. No. 1 Volt % Absolute accelerator pedal position No. 1 - Accel Sens. No. 2 Volt % Absolute accelerator pedal position No. 2 - Throttle Sensor Volt % Absolute throttle position sensor The throttle opening angle recognized by the ECM.

Read the value with the ignition switch ON.

Throttl Sensor #2 Volt % Absolute throttle position sensor #2 The throttle opening angle recognized by the ECM.

Read the value with the ignition switch ON.

Throttle Sensor Position Throttle sensor position A calculated value based on VTA1.

Read the value with the ignition switch ON.

Throttle Motor DUTY Throttle actuator - Throttle Position Throttle position For use when engine stall, starting problems or rough idle is present. ISC Flow Flow rate calculated using information from each sensor For use when engine stall, starting problems or rough idle is present. ISC Position Requested opening amount calculated using ISC control This is the throttle valve opening amount while the engine is idling (the throttle valve opening amount necessary to maintain ISC air flow). ISC Feedback Value ISC feedback compensation amount For use when engine stall, starting problems or rough idle is present. ISC Learning Value ISC learned compensation amount For use when engine stall, starting problems or rough idle is present. Electric Load Feedback Val Compensation flow rate according to electrical load For use when engine stall, starting problems or rough idle is present. Air Conditioner FB Val Compensation flow rate according to air conditioner load For use when engine stall, starting problems or rough idle is present. Low Revolution Control Low engine speed control operation state For use when engine stall, starting problems or rough idle is present. Eng Stall Control FB Flow Intake air compensation flow rate For use when engine stall, starting problems or rough idle is present. Injector (Port) Injection period of No. 1 cylinder - Injection Volum (Cylinder1) Injection volume (cylinder 1) The quantity of fuel injection volume for 10 times. Fuel Pump/Speed Status Fuel pump/status - Current Fuel Type Status of the current fuel type - EVAP (Purge) VSV EVAP (purge) VSV control duty The order signal from the ECM. Evap Purge Flow Ratio of evaporative purge flow to intake air volume - Purge Density Learn Value Learned value of purge density - EVAP Purge VSV VSV status for EVAP control - Purge Cut VSV Duty Purge cut VSV duty - Target Air-Fuel Ratio Ratio compared to stoichiometric level - AF Lambda B1S1 Fuel trim at A/F sensor - AFS Voltage B1S1 A/F sensor output voltage for bank 1 sensor 1 Performing the Control the Injection Volume or Control the Injection Volume for A/F Sensor function of the Active Test enables the technician to check the output voltage of the sensor. AFS Current B1S1 Air fuel ratio sensor output current for bank 1 sensor 1 - A/F Heater Duty #1 Air fuel ratio sensor heater duty ratio for bank 1 sensor 1 - O2S B1S2 Heated oxygen sensor output voltage for bank 1 sensor 2 Performing the Control the Injection Volume or Control the Injection Volume for A/F Sensor function of the Active Test enables the technician to check the output voltage of the sensor. O2S Impedance B1S2 Heated oxygen sensor impedance for bank 1 sensor 2 - O2 Heater B1S2 Heated oxygen sensor heater for bank 1 sensor 2 - O2 Heater Curr Val B1S2 Heated oxygen sensor current for bank 1 sensor 2 - Short FT #1 Short-term fuel trim of bank 1 Short-term fuel compensation is used to maintain the air-fuel ratio at the stoichiometric air-fuel ratio. Long FT #1 Long-term fuel trim of bank 1

-

Overall fuel compensation is carried out in the long term to compensate for a continual deviation of the short-term fuel trim from the central value.

-

Air fuel ratio feedback leaning is divided up according to the engine operating range (engine speed x load), and separate values are stored for each operating range. "Long FT #1" indicates the learned value for the current operating range. [A/F Learn Value Idle #1], [A/F Learn Value Low #1], [A/F Learn Value Mid1 #1], [A/F Learn Value Mid2 #1] and [A/F Learn Value High #1] indicate the leaned values for the different operating ranges. The learned value that is the same as "Long FT #1" indicates the current engine operating range.

A/F Learn Value Idle #1 Air fuel ratio learn value area of idle (for bank 1) Learning is performed when idling with the engine warmed up (engine coolant temperature is 80°C [176°F] or higher). A/F Learn Value Low #1 Air fuel ratio learn value area of low load (for bank 1) Learning is performed when driving with the engine warmed up (engine coolant temperature is 80°C [176°F] or higher) and operating in the low load range (when the range of engine loads is divided into four parts). A/F Learn Value Mid1 #1 Air fuel ratio learn value area of middle load 1 (for bank 1) Learning is performed when driving with the engine warmed up (engine coolant temperature is 80°C [176°F] or higher) and operating in the midsize load range closer to the low load range (when the range of engine loads is divided into four parts). A/F Learn Value Mid2 #1 Air fuel ratio learn value area of middle load 2 (for bank 1) Learning is performed when driving with the engine warmed up (engine coolant temperature is 80°C [176°F] or higher) and operating in the midsize load range closer to the high load range (when the range of engine loads is divided into four parts). A/F Learn Value High #1 Air fuel ratio learn value area of high load (for bank 1) Learning is performed when driving with the engine warmed up (engine coolant temperature is 80°C [176°F] or higher) and operating in the high load range (when the range of engine loads is divided into four parts). Total FT #1 Total fuel trim of bank 1 - Fuel System Status #1 Fuel system status (bank 1)

-

OL (Open Loop): Has not yet satisfied the conditions to go to closed loop.

-

CL (Closed Loop): Using the heated oxygen sensor as feedback for fuel control.

-

OL Drive: Open loop due to driving conditions (fuel enrichment).

-

OL Fault: Open loop due to a detected system fault.

-

CL Fault: Closed loop but the heated oxygen sensor, which is used for fuel control, is malfunctioning.

Fuel System Status #2 Fuel system status (bank 2) IGN Advance Ignition timing advance for No. 1 cylinder - Knock Feedback Value Feedback value of knocking - Knock Correct Learn Value Learned knocking correction value - Idle Spark Advn Ctrl #1 Individual cylinder timing advance compensation amount (No. 1) For use when the engine stalls, is difficult to start, or idles roughly. Idle Spark Advn Ctrl #2 Individual cylinder timing advance compensation amount (No. 2) For use when the engine stalls, is difficult to start, or idles roughly. Idle Spark Advn Ctrl #3 Individual cylinder timing advance compensation amount (No. 3) For use when the engine stalls, is difficult to start, or idles roughly. Idle Spark Advn Ctrl #4 Individual cylinder timing advance compensation amount (No. 4) For use when the engine stalls, is difficult to start, or idles roughly. ACIS VSV VSV for acoustic control induction system (ACIS) - Actual VVT Angle #1 Actual VVT displacement angle (bank 1) This item is used for freeze frame data only Actual VVT Ex Angle #1 Actual VVT exhaust displacement angle (bank 1) This item is used for freeze frame data only VVT Control Status #1 VVT control (bank 1) status - VVT Advance Fail VVT control failure status - VALVEMATIC Target Angle VALVEMATIC target duration - VALVEMATIC Current Angle Actual VALVEMATIC duration Minimum duration: 106 deg(CA)

Maximum duration: 260 deg(CA)

VALVEMATIC IG OFF VALVEMATIC operation state One of the items which shows the operating state of the VALVEMATIC is ON. VALVEMATIC IG ON VALVEMATIC operation state VALVEMATIC Cranking VALVEMATIC operation state VALVEMATIC bef Warm Up VALVEMATIC operation state VALVEMATIC aft Warm Up VALVEMATIC operation state VALVEMATIC IDM Hi Temp VALVEMATIC operation state VALVEMATIC Low (ACT) VALVEMATIC operation state VALVEMATIC High (ACT) VALVEMATIC operation state Catalyst Temp B1S1 Estimated catalyst temperature (for sensor 1) - Catalyst Temp B1S2 Estimated catalyst temperature (for sensor 2) - Starter Signal Starter signal (STA terminal input status) - Power Steering Signal Power steering switch status - Power Steer. Sig. Record Power Steering Signal (history) Signal status usually ON until battery terminals disconnected Clutch Switch Clutch switch status - Reverse Switch Reverse switch status - Stop Light Switch Stop light switch status - Shift Indication Enable Shift indication enable - A/C Signal A/C switch status - Closed Throttle Position SW Closed throttle position switch - Fuel Cut Condition Fuel-cut condition - Immobiliser Communication Immobiliser communication - Electrical Load Signal Electrical load signal - ASL Switch Adjustable speed limiter switch signal - TC Terminal TC terminal status - Time after DTC Cleared Cumulative time after DTC cleared - Distance from DTC Cleared Total distance vehicle driven after DTC cleared - Warmup Cycle Cleared DTC Warm-up cycle after DTC cleared - Dist Batt Cable Disconnect Total distance vehicle driven after battery cable disconnected - IG OFF Elapsed Time Cumulative time after ignition switch off - TC and TE1 TC and CG (TE1) terminals of DLC3 - Ignition Trig. Count Ignition counter to calculated misfire count - Cylinder #1 Misfire Count Misfire count of cylinder 1 - Cylinder #2 Misfire Count Misfire count of cylinder 2 - Cylinder #3 Misfire Count Misfire count of cylinder 3 - Cylinder #4 Misfire Count Misfire count of cylinder 4 - All Cylinders Misfire Count All cylinders misfire count - Misfire RPM Average engine speed when misfire occurs - Misfire Load Average engine load when misfire occurred - Misfire Margin Margin to detect engine misfire - Engine Speed (Starter Off) Engine speed when starter off For use when engine stall, starting problems or rough idle is present. Starter Count Number of times starter turned on after ignition switch ON For use when engine stall, starting problems or rough idle is present. Run Dist of Previous Trip Distance driven during previous trip Before 5 seconds elapse after starting the engine, which is the DTC P1604 (Startability Malfunction) detection duration, this parameter indicates the distance driven during the previous trip.

After 5 seconds elapse after starting the engine, this parameter indicates the distance driven during the current trip calculated from the vehicle speed signal.

Tech Tips

Run Dist of Previous Trip in the freeze frame data present when the startability malfunction occurred (DTC P1604 detected) indicates the distance driven during the previous trip, but in all other cases, such as for the snapshot data of the Data List (real-time measurements), or for freeze frame data present when DTCs other than P1604 were detected, the value indicates the distance driven during the current trip.

Engine Starting Time Time elapsed after engine started (interval between ignition switch ON and off) For use when engine stall, starting problems or rough idle is present. Previous Trip Coolant Temp Engine coolant temperature during previous trip For use when engine stall, starting problems or rough idle is present. Previous Trip Intake Temp Intake air temperature during previous trip For use when engine stall, starting problems or rough idle is present. Engine Oil Temperature Engine oil temperature (estimated temperature) For use when engine stall, starting problems or rough idle is present. Previous Trip Eng Oil Temp Engine oil temperature during previous trip For use when engine stall, starting problems or rough idle is present. Ambient Temp for A/C Ambient temperature for A/C For use when engine stall, starting problems or rough idle is present. Previous Trip Ambient Temp Ambient temperature during previous trip For use when engine stall, starting problems or rough idle is present. Engine Start Hesitation History of hesitation during engine start - Low Rev for Eng Start History of low engine speed after engine start - Minimum Engine Speed Minimum engine speed For use when engine stall, starting problems or rough idle is present. Fuel Cut Elps Time Time elapsed after engine runs at high speed The time elapsed after a fuel cut after high engine speed has occurred (more than the rpm at which fuel cut occurs +500 rpm). Electric Fan Motor Electric fan motor status - Brake Override System Brake override system status - Idle Fuel Cut Fuel cut idle ON: When the throttle valve is fully closed and the engine speed is more than 2800 rpm. FC TAU Fuel cut during very light load The fuel cut is being performed under a very light load to prevent the engine combustion from becoming incomplete. Immobiliser Fuel Cut Status of immobiliser fuel cut - Immobiliser Fuel Cut History Immobiliser fuel cut history For use when starting problems is present. Comm with Power Manage Status of communication with power management control ECU - Comm with Air Conditioner Status of communication with air conditioning amplifier - Communication with VALVEMATIC Status of communication with VALVEMATIC system - Electrical Load Signal 1 Electrical load signal - Electrical Load Signal 2 Electrical load signal - MT Down Shift Indication M/T down shift indication - MT Up Shift Indication M/T up shift indication - -