BRAKE BOOSTER PUMP INSTALLATION

-

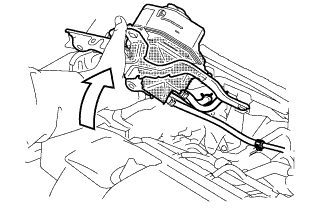

INSTALL BRAKE BOOSTER PUMP ASSEMBLY

-

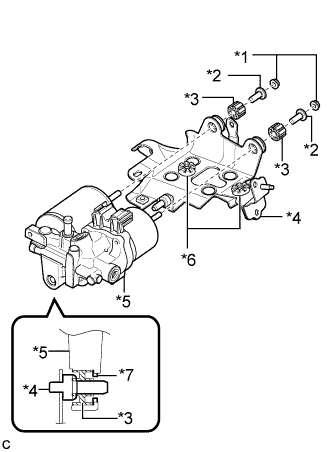

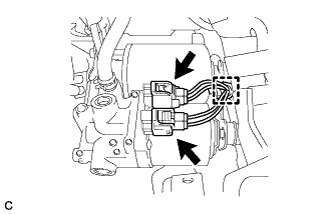

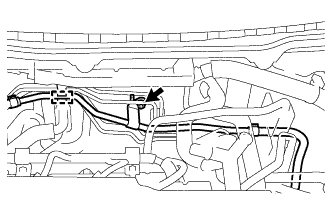

Text in Illustration *1 Nut *2 Brake Actuator Case Collar *3 Brake Booster Pump Bushing *4 Brake Actuator Bracket Assembly *5 Brake Booster Pump Assembly *6 Brake Actuator Bracket Cushion *7 Brake Booster Pump Collar Install the brake booster pump assembly, 2 brake booster pump bushings and 2 brake actuator case collars to the brake actuator bracket assembly with the 2 nuts.

- Torque:

- 5.4 N*m { 55 kgf*cm, 48 in.*lbf }

Note

-

Do not drop the brake booster pump assembly when carrying it.

-

Do not carry the brake booster pump assembly by the connector.

-

Confirm that the 2 brake actuator bracket cushions are on the brake actuator bracket assembly, and each brake booster pump bushing and brake booster pump collar are on the brake booster pump assembly when installing the brake booster pump assembly to the brake actuator bracket assembly.

-

Do not remove the hole plugs before installing a new brake booster pump assembly because the brake booster pump assembly is filled with brake fluid.

-

-

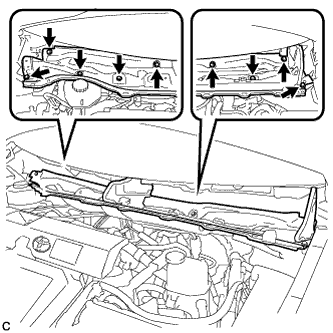

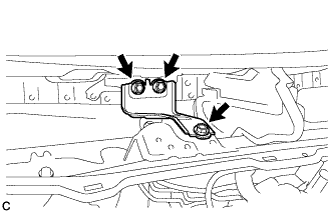

INSTALL BRAKE BOOSTER PUMP ASSEMBLY WITH BRACKET

-

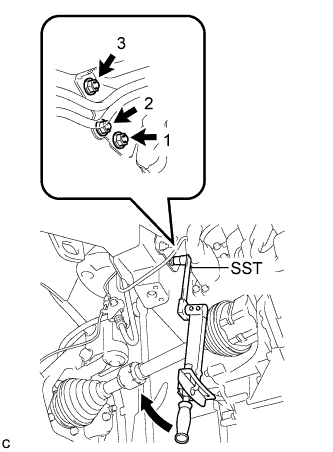

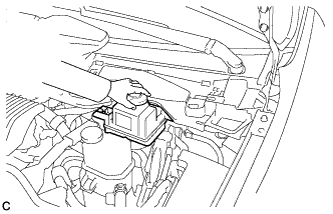

Using SST, install the brake booster pump assembly with bracket with the 3 nuts.

- Torque:

- without SST

- 19 N*m { 194 kgf*cm, 14 ft.*lbf }

- with SST

- 12 N*m { 121 kgf*cm, 9 ft.*lbf }

Note

-

Use a torque wrench with a fulcrum length of 250 mm (9.84 in.).

-

Tighten the 3 nuts in the order shown in the illustration.

-

Do not damage the fuel line, the brake lines and wire harness.

-

Use the formula to calculate special torque values for situations where SST is combined with a torque wrench Click here.

-

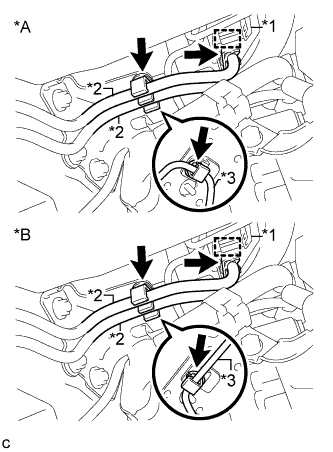

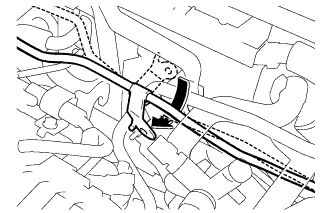

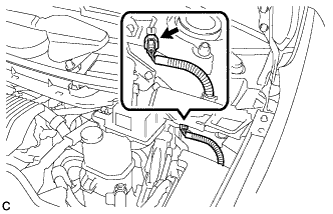

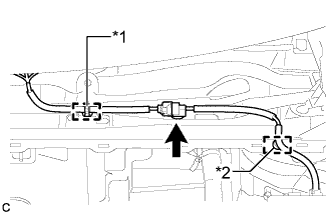

Text in Illustration *A for LHD *B for RHD *1 Wire Harness Clamp *2 Fuel Line *3 Front No. 4 Brake Tube Install the wire harness clamp, 2 fuel lines and front No. 4 brake tube to the brake actuator bracket assembly.

Note

Do not damage the fuel line, brake lines and wire harness.

-

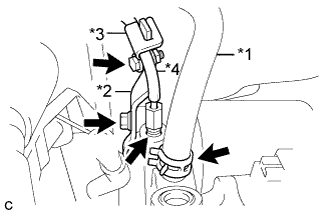

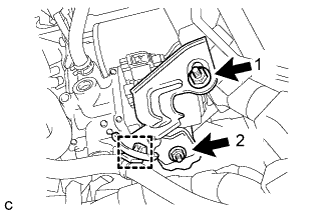

Text in Illustration *1 Brake Actuator Hose *2 No. 1 Brake Tube Clamp Bracket *3 No. 7 Brake Tube Clamp *4 Front No. 1 Brake Tube Install the No. 1 brake tube clamp bracket to the brake booster pump assembly with the bolt.

- Torque:

- 7.0 N*m { 71 kgf*cm, 62 in.*lbf }

-

Using a union nut wrench, connect the front No. 1 brake tube to the brake booster pump assembly.

- Torque:

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where the union nut wrench is combined with a torque wrench Click here.

-

Install the No. 7 brake tube clamp to the No. 1 brake tube clamp bracket with the bolt.

- Torque:

- 7.0 N*m { 71 kgf*cm, 62 in.*lbf }

-

Connect the brake actuator hose to the brake booster pump assembly with the clip (for RHD).

-

Install the wire harness clamp.

-

Connect the 2 connectors.

-

-

INSTALL NO. 5 BRAKE ACTUATOR BRACKET (for RHD)

-

Install the No. 5 brake actuator bracket with the 2 nuts.

- Torque:

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

Note

Tighten the 2 nuts in the order shown in the illustration.

-

Install the wire harness clamp.

-

-

INSTALL FRONT SUSPENSION CROSSMEMBER SUB-ASSEMBLY

-

INSTALL BRAKE BOOSTER WITH MASTER CYLINDER ASSEMBLY (for LHD)

-

SEPARATE BRAKE MASTER CYLINDER RESERVOIR WITH BRACKET (for RHD)

-

Disengage the clamp.

-

Remove the 2 nuts and separate the brake master cylinder reservoir with bracket.

-

-

BLEED NO. 1 BRAKE ACTUATOR TUBE (for RHD)

Note

Make sure to bleed the air from the No. 1 brake actuator tube. If the air remains in the No. 1 brake actuator tube, the air enters into the brake booster pump assembly and it may cause the brake booster pump assembly to be damaged.

-

Remove the brake master cylinder reservoir filler cap assembly.

-

Add brake fluid into the reservoir between the MAX and MIN level on the brake fluid reservoir.

Brake Fluid SAE J1703 or FMVSS No. 116 DOT3 -

Install the brake master cylinder reservoir filler cap assembly.

-

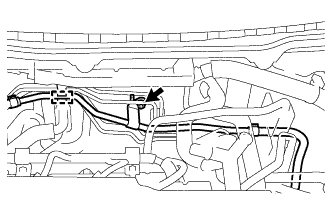

Remove the nut, disengage the clamp and separate the No. 1 brake actuator tube from the vehicle body.

-

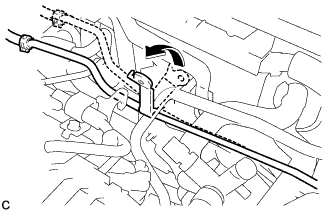

Lift up the brake master cylinder reservoir with bracket as far as possible.

Note

Do not spill the brake fluid.

-

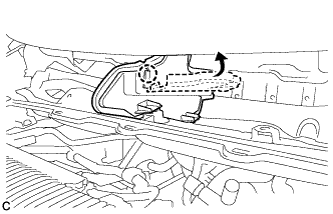

While holding the brake master cylinder reservoir with bracket, twist and hold the No. 1 brake actuator tube 90° toward the vehicle front, and wait at 5 seconds.*1

Note

Do not damage the hoses.

Tech Tips

Keeping the No. 1 brake actuator tube twisted causes the remaining air inside the No. 1 brake actuator tube to be expelled to the brake master cylinder reservoir assembly.

-

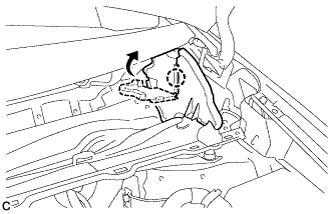

Return the No. 1 brake actuator tube to its original state.

-

While holding the brake master cylinder reservoir with bracket, twist and hold the No. 1 brake actuator tube 90° toward the vehicle rear, and wait at 5 seconds.

Note

Do not damage the hoses.

Tech Tips

Keeping the No. 1 brake actuator tube twisted causes the remaining air inside the No. 1 brake actuator tube to be expelled to the brake master cylinder reservoir assembly.

-

Return the No. 1 brake actuator tube to its original state.*2

-

Repeat steps *1 to *2, 5 times.

-

While holding the brake master cylinder reservoir with bracket, pinch the brake actuator hose 10 times with your fingers.

Note

Do not use pliers or similar to pinch the brake actuator hose. Doing so may cause damage to the brake actuator hose. Make sure to use your fingers.

-

Repeat steps *1 to *2, 5 times again, and check that air is not expelled from the No. 1 brake actuator tube.

-

Engage the clamp and install the No. 1 brake actuator tube with the nut.

- Torque:

- 8.4 N*m { 85 kgf*cm, 74 in.*lbf }

-

-

INSTALL BRAKE MASTER CYLINDER RESERVOIR WITH BRACKET (for RHD)

-

Install the brake master cylinder reservoir with bracket with the 2 nuts.

- Torque:

- 50 N*m { 510 kgf*cm, 37 ft.*lbf }

-

Engage the clamp.

-

-

FILL RESERVOIR WITH BRAKE FLUID (for RHD)

-

CONNECT CABLE TO NEGATIVE AUXILIARY BATTERY TERMINAL (for RHD)

-

BLEED BRAKE SYSTEM (for RHD)

-

Remove the outer cowl top panel sub-assembly.

-

for LHD: Click here

-

for RHD: Click here

-

-

Bleed the brake system.

-

Wait at least 2 minutes with the power switch off, and disconnect the reservoir level switch connector.

Note

Do not depress the brake pedal or open/close the doors until the reservoir level switch connector is disconnected.

Tech Tips

This procedure is not required if the reservoir level switch connector has been disconnected.

-

Remove the brake master cylinder reservoir filler cap assembly.

-

Add brake fluid into the reservoir between MAX and MIN level on the brake fluid reservoir.

Brake fluid SAE J1703 or FMVSS No. 116 DOT3 -

Connect the GTS to the DLC3 and turn the power switch on (IG).

-

Turn the GTS on and enter the following menus: Chassis / ABS/VSC/TRC / Air Bleeding.

-

Select "ABS actuator has been replaced" on the GTS display, and bleed air from the brake fluid following the instructions on the GTS.

Note

Before following the instructions on the GTS to perform linear valve offset calibration, release the parking brake. When calibration is complete, immediately apply the parking brake.

-

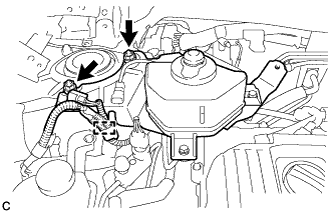

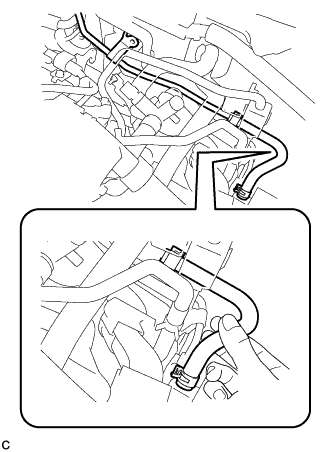

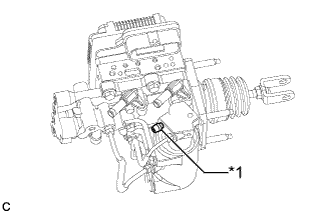

Text in Illustration *1 Stroke Simulator Bleeder Plug After air bleeding, tighten each bleeder plug.

- Torque:

- front bleeder plug

- 8.3 N*m { 85 kgf*cm, 73 in.*lbf }

- rear bleeder plug

- 11 N*m { 112 kgf*cm, 8 ft.*lbf }

- stroke simulator bleeder plug

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

Tech Tips

The stroke simulator bleeder plug is positioned as shown in the illustration.

-

Clear the DTCs Click here.

-

Turn the GTS off and turn the power switch off.

-

-

Install the brake master cylinder reservoir filler cap.

-

Inspect for brake fluid leaks.

-

Install the outer cowl top panel sub-assembly.

-

for LHD: Click here

-

for RHD: Click here

-

-

-

INSTALL OUTER COWL TOP PANEL SUB-ASSEMBLY (for RHD)

-

Install the outer cowl top panel sub-assembly with the 9 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

Bend the water guard plate RH and engage the claw.

-

Bend the No. 1 heater air duct splash shield seal and engage the claw.

-

Engage the clamp*2 of the wire harness.

-

Engage the clamp*1 and connect the connector (w/ Windshield Deicer).

-

Engage the clamp of the wire harness.

-

-

INSTALL COWL BODY MOUNTING REINFORCEMENT RH (for RHD)

-

Install the cowl body mounting reinforcement RH with the 3 bolts.

- Torque:

- 12 N*m { 122 kgf*cm, 9 ft.*lbf }

-

-

INSTALL WINDSHIELD WIPER MOTOR AND LINK ASSEMBLY (for RHD)