HYBRID CONTROL SYSTEM, Diagnostic DTC:P0A78-286

| DTC Code | DTC Name |

|---|---|

| P0A78-286 | Drive Motor "A" Inverter Performance |

DESCRIPTION

For a description of the inverter Click here.

If the motor inverter overheats, has a circuit malfunction, or has an internal short, the inverter transmits this information to the MG ECU via the motor inverter fail signal line.

Tech Tips

The term "drive motor A" indicates MG2.

| DTC No. | INF Code | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| P0A78 | 286 | Motor inverter fail signal detection (circuit malfunction) (1 trip detection logic) |

|

WIRING DIAGRAM

Refer to the wiring diagram for DTC P1CAC-200 Click here.

Refer to the wiring diagram for DTC P0AA6-526 Click here.

Refer to the wiring diagram for DTC P324E-788 Click here.

Refer to the wiring diagram for DTC U0110-159 Click here.

CAUTION / NOTICE / HINT

CAUTION:

-

Before inspecting the high-voltage system or disconnecting the low voltage connector of the inverter with converter assembly, take safety precautions such as wearing insulated gloves and removing the service plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work Click here.

Tech Tips

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

Note

After turning the ignition switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work Click here.

Tech Tips

After the repair, clear the DTCs and perform the following procedure to check that DTCs are not output.

-

Turn the ignition switch to ON (READY) and wait for 10 seconds or more.

-

Perform a road test according to the freeze frame data "Vehicle Spd" for approximately 10 minutes.

PROCEDURE

-

CHECK DTC OUTPUT (HYBRID CONTROL)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Check if DTCs are output.

Result Result Proceed to P0A78-202 is not output. A P0A78-202 is also output. B Note

-

If P0A78-202 is output, troubleshoot it first. After completing the troubleshooting for P0A78-202, return to perform troubleshooting for this DTC.

-

Parts repaired or replaced during troubleshooting for P0A78-202 do not need to be re-inspected in this diagnosis procedure.

-

-

Turn the ignition switch off.

B

GO TO DTC CHART (P0A78-202) Click here

A

-

-

CHECK DTC OUTPUT (HYBRID CONTROL)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Check if DTCs are output.

Tech Tips

-

If P0A78-202 was not output in step 1 of this diagnosis procedure, check Table 1 below.

-

If P0A78-202 was output in step 1 of this diagnosis procedure, repair that DTC first, then check Table 2 below.

Result Result Proceed to Only P0A78-286 is output, or DTCs other than the ones in the table below are also output. A Any of the following DTCs are also output. B Table 1 DTC No. Relevant Diagnosis P06B0-163 Sensor Power Supply "A" Circuit/Open P06D6-511 Sensor Reference Voltage "F" Circuit/Open P06E6-164 Sensor Power Supply "C" Circuit/Open P0A1A-151, 166, 517, 658, 791, 809 Generator Control Module P0A1B-198, 503, 505, 547, 554, 786, 794, 806 Drive Motor "A" Control Module P0A1D (all INF codes)*1 Hybrid Powertrain Control Module P0A3F-243 Drive Motor "A" Position Sensor Circuit P0A40-500, 504, 506, 549, 556, 808 Drive Motor "A" Position Sensor Circuit Range/Performance P0A41-245 Drive Motor "A" Position Sensor Circuit Low P0A4B-253 Generator Position Sensor Circuit P0A4C-513, 518, 811 Generator Position Sensor Circuit Range/Performance P0A4D-255 Generator Position Sensor Circuit Low P0A78-113, 128, 279, 284, 287, 548, 555, 807 Drive Motor "A" Inverter Performance P0A7A-122, 130, 322, 325, 810 Generator Inverter Performance P0A90-509 Drive Motor "A" Performance P0A92-521 Hybrid Generator Performance P0BEA-290 Drive Motor "A" Phase V Current Sensor Circuit Range/Performance P0BEE-298 Drive Motor "A" Phase W Current Sensor Circuit Range/Performance P0C19-306 Drive Motor "A" Torque Delivered Performance P0C73-776 Motor Electronics Coolant Pump "A" Control Performance P0C76-523 Hybrid Battery System Discharge Time Too Long P0CA3-442 DC/DC Converter Step Up Voltage Performance P0D2E-586 Drive Motor "A" Inverter Voltage Sensor Circuit Range/Performance P0D2F-266 Drive Motor "A" Inverter Voltage Sensor Circuit Low P0D30-267 Drive Motor "A" Inverter Performance P0E05-328 Generator Phase V Current Sensor Circuit Range/Performance P0E09-336 Generator Phase W Current Sensor Circuit Range/Performance P0E32-585 DC/DC Converter Voltage Sensor "A" Range/Performance P0E33-589 DC/DC Converter Voltage Sensor "A" Low P0E34-590 DC/DC Converter Voltage Sensor "A" High P0E71-344 Generator Torque Delivered Performance P1C2A-155 Generator A/D Converter Circuit P1C2B-192 Drive Motor "A" A/D Converter Circuit P1C2D-587 Hybrid Battery Voltage / DC/DC Converter Voltage Correlation P1C3C-294 Drive Motor "A" Phase V Current Sensor Correlation P1C3D-302 Drive Motor "A" Phase W Current Sensor Correlation P1C3E-333 Generator Phase V Current Sensor Correlation P1C3F-341 Generator Phase W Current Sensor Correlation P1C4A-288 Drive Motor "A" Phase V Current Sensor Sub Circuit Range/Performance P1C4F-296 Drive Motor "A" Phase W Current Sensor Sub Circuit Range/Performance P1C54-326 Generator Phase V Current Sensor Sub Circuit Range/Performance P1C59-334 Generator Phase W Current Sensor Sub Circuit Range/Performance P1C6D-501 Drive Motor "A" Phase V Current Sensor Offset Range/Performance P1C6E-502 Drive Motor "A" Phase W Current Sensor Offset Range/Performance P1C71-515 Generator Phase V Current Sensor Offset Range/Performance P1C72-516 Generator Phase W Current Sensor Offset Range/Performance P1C73-512 Sensor Standard Voltage "F" Circuit/Open P1CA6-156 Generator Control Module Malfunction P1CA7-193 Drive Motor Control Module Malfunction P1CAC-200 Generator Position Sensor Angle Malfunction P1CAD-168 Drive Motor "A" Position Sensor Angle Malfunction P1CAF-792 Generator Position Sensor REF Signal Cycle Malfunction P1CB0-795 Drive Motor "A" Position Sensor REF Signal Cycle Malfunction P1CB2-793 Generator Position Sensor REF Signal Stop Malfunction P1CB3-796 Drive Motor "A" Position Sensor REF Signal Stop Malfunction P3133-659 Communication Error from Generator to Drive Motor "A" P3134-661 Communication Error from Drive Motor "A" to Generator P314A-828 Inverter Coolant Pump Speed Signal Table 2 DTC No. Relevant Diagnosis P06B0-163 Sensor Power Supply "A" Circuit/Open P06D6-511 Sensor Reference Voltage "F" Circuit/Open P06E6-164 Sensor Power Supply "C" Circuit/Open P0A1A-151, 166, 517, 658, 791, 809 Generator Control Module P0A1B-198, 503, 505, 547, 554, 786, 794, 806 Drive Motor "A" Control Module P0A1D (all INF codes)*1 Hybrid Powertrain Control Module P0A3F-243 Drive Motor "A" Position Sensor Circuit P0A40-500, 504, 506, 549, 556, 808 Drive Motor "A" Position Sensor Circuit Range/Performance P0A41-245 Drive Motor "A" Position Sensor Circuit Low P0A4B-253 Generator Position Sensor Circuit P0A4C-513, 518, 811 Generator Position Sensor Circuit Range/Performance P0A4D-255 Generator Position Sensor Circuit Low P0A78-113, 128, 279, 284, 287, 548, 555, 807 Drive Motor "A" Inverter Performance P0A7A-122, 130, 322, 325, 810 Generator Inverter Performance P0A92-521 Hybrid Generator Performance P0C73-776 Motor Electronics Coolant Pump "A" Control Performance P0C76-523 Hybrid Battery System Discharge Time Too Long P0CA3-442 DC/DC Converter Step Up Voltage Performance P0D2E-586 Drive Motor "A" Inverter Voltage Sensor Circuit Range/Performance P0D2F-266 Drive Motor "A" Inverter Voltage Sensor Circuit Low P0D30-267 Drive Motor "A" Inverter Performance P0E05-328 Generator Phase V Current Sensor Circuit Range/Performance P0E09-336 Generator Phase W Current Sensor Circuit Range/Performance P0E32-585 DC/DC Converter Voltage Sensor "A" Range/Performance P0E33-589 DC/DC Converter Voltage Sensor "A" Low P0E34-590 DC/DC Converter Voltage Sensor "A" High P0E71-344 Generator Torque Delivered Performance P1C2A-155 Generator A/D Converter Circuit P1C2B-192 Drive Motor "A" A/D Converter Circuit P1C2D-587 Hybrid Battery Voltage / DC/DC Converter Voltage Correlation P1C3C-294 Drive Motor "A" Phase V Current Sensor Correlation P1C3D-302 Drive Motor "A" Phase W Current Sensor Correlation P1C3E-333 Generator Phase V Current Sensor Correlation P1C3F-341 Generator Phase W Current Sensor Correlation P1C54-326 Generator Phase V Current Sensor Sub Circuit Range/Performance P1C59-334 Generator Phase W Current Sensor Sub Circuit Range/Performance P1C71-515 Generator Phase V Current Sensor Offset Range/Performance P1C72-516 Generator Phase W Current Sensor Offset Range/Performance P1C73-512 Sensor Standard Voltage "F" Circuit/Open P1CA6-156 Generator Control Module Malfunction P1CA7-193 Drive Motor Control Module Malfunction P1CAC-200 Generator Position Sensor Angle Malfunction P1CAD-168 Drive Motor "A" Position Sensor Angle Malfunction P1CAF-792 Generator Position Sensor REF Signal Cycle Malfunction P1CB0-795 Drive Motor "A" Position Sensor REF Signal Cycle Malfunction P1CB2-793 Generator Position Sensor REF Signal Stop Malfunction P1CB3-796 Drive Motor "A" Position Sensor REF Signal Stop Malfunction P3133-659 Communication Error from Generator to Drive Motor "A" P3134-661 Communication Error from Drive Motor "A" to Generator P314A-828 Inverter Coolant Pump Speed Signal Tech Tips

-

*1: If any INF codes are output for this DTC, refer to the corresponding diagnostic procedure.

-

P0A78-286 may be set due to a malfunction which also causes DTCs in the preceding table to be set. In this case, first troubleshoot the output DTCs in the preceding table.

-

-

Turn the ignition switch off.

B

GO TO DTC CHART (HYBRID CONTROL SYSTEM) Click here

A

-

-

CHECK CONNECTOR CONNECTION CONDITION (INVERTER WITH CONVERTER ASSEMBLY CONNECTOR)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Check the connector connections and contact pressure of the low voltage connectors of the inverter with converter assembly Click here.

Note

Before disconnecting the connector, confirm that it is properly connected by checking that the locking claws are engaged and that the connector does not pull out.

OK The connectors are connected securely and there are no contact pressure problems. Tech Tips

When connecting the connector, insert it with the locking lever in the raised position. Rotate the lever downward and make sure that the connector is pulled into its socket. When the locking lever is in its fully closed position, a click will be heard as its locking claws engage. After the click is heard, pull up on the connector to confirm that it is properly connected.

NG

CONNECT SECURELY

OK

-

-

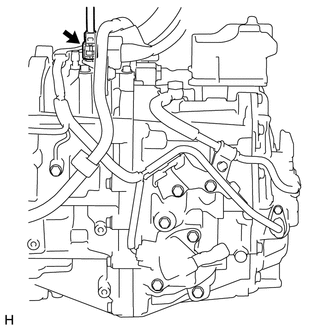

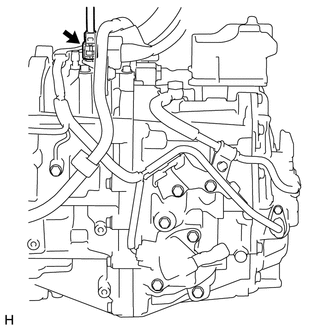

CHECK QUANTITY OF HV COOLANT

-

Check the HV coolant level in the inverter reserve tank.

-

Check for HV coolant leaks.

Result Result Proceed to No leaks are found and coolant level in the inverter reserve tank assembly is above the low line. A No leaks are found and coolant level in the inverter reserve tank assembly is below the low line. B HV coolant leaks are evident. C Tech Tips

-

After repairing the HV coolant leaks and adding coolant, perform the "Activate the Water Pump" Active Test (HV Active Test item) and the "Control the Electric Cooling Fan" Active Test (Engine Active Test item) and make sure that there are no malfunctions.

-

The inverter water pump assembly will not malfunction due to coolant leaks.

-

B

ADD HV COOLANT

C

INSPECT FOR HV COOLANT LEAK AND ADD HV COOLANT

A

-

-

CHECK COOLANT HOSE

-

Check if the hoses of the cooling system are kinked or clogged.

NG

CORRECT THE PROBLEM

OK

-

-

PERFORM ACTIVE TEST USING GTS (CONTROL THE ELECTRIC COOLING FAN)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON (IG).

-

Clear DTCs Click here.

-

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Electric Cooling Fan.

-

Perform the "Control the Electric Cooling Fan" Active Test.

OK The cooling fan rotates. -

Turn the ignition switch off.

NG

CHECK COOLING FAN SYSTEM Click here

OK

-

-

CHECK HV COOLANT (CHECK FOR CONDITIONS THAT MAY HAVE CAUSED FREEZING)

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Read the freeze frame data Ambient Temperature using the GTS.

-

Check if the freeze frame data Ambient Temperature is below freezing.

Result Result Proceed to Ambient Temperature value is above freezing temperature of the HV coolant. A Ambient Temperature value is below freezing temperature of the HV coolant. B Tech Tips

-

HV coolant (SLLC) with a 30% concentration freezes at -15°C (5°F) and HV coolant (SLLC) with a 50% concentration freezes at -35°C (-31°F).

-

If the HV coolant freezes in the HV radiator or HV water pump, the coolant temperature in the inverter with converter assembly rises because the HV coolant cannot circulate. As a result, a DTC may be set.

-

A DTC is set when the water pump impeller cannot rotate due to freezing of the HV coolant.

-

If a DTC is set due to freezing of HV coolant, the problem cannot be reproduced. Judge whether freezing of HV coolant occurred according to the freeze point of the HV coolant, HV coolant change history and ambient temperature when the DTC was set.

-

-

Turn the ignition switch off.

B

REPLACE HV COOLANT Click here

A

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - GENERATOR RESOLVER)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the inverter with converter assembly connector.

-

Connect the cable to the negative (-) auxiliary battery terminal.

-

Turn the ignition switch to ON (IG).

-

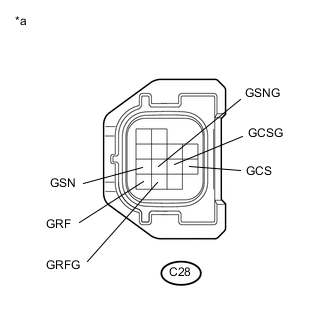

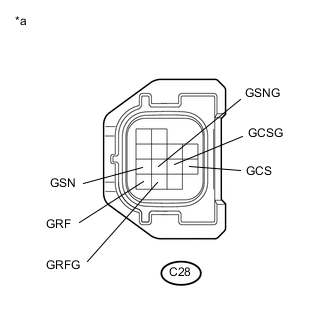

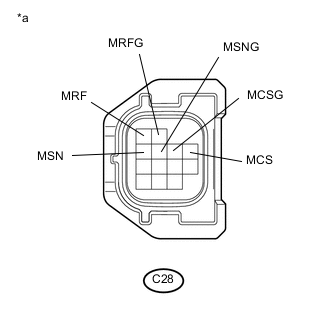

Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition C28-11 (GRF) - Body ground Ignition switch ON (IG) Below 1 V C28-12 (GRFG) - Body ground Ignition switch ON (IG) Below 1 V C28-7 (GSN) - Body ground Ignition switch ON (IG) Below 1 V C28-8 (GSNG) - Body ground Ignition switch ON (IG) Below 1 V C28-10 (GCS) - Body ground Ignition switch ON (IG) Below 1 V C28-9 (GCSG) - Body ground Ignition switch ON (IG) Below 1 V Note

Turning the ignition switch to ON (IG) with the low voltage connector of the inverter with converter assembly disconnected causes other DTCs to be stored. Clear the DTCs after performing this inspection.

-

Turn the ignition switch off.

-

Disconnect the cable from the negative (-) auxiliary battery terminal.

-

Connect the inverter with converter assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK GENERATOR RESOLVER

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the inverter with converter assembly connector.

-

Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Switch Condition Specified Condition C28-11 (GRF) - C28-12 (GRFG) Ignition switch off 7.1 to 21.6 Ω C28-7 (GSN) - C28-8 (GSNG) Ignition switch off 13.7 to 34.5 Ω C28-10 (GCS) - C28-9 (GCSG) Ignition switch off 12.8 to 32.4 Ω Standard Resistance (Check for Short) Tester Connection Switch Condition Specified Condition C28-11 (GRF) or C28-12 (GRFG) - Body ground and other terminals Ignition switch off 1 MΩ or higher C28-7 (GSN) or C28-8 (GSNG) - Body ground and other terminals Ignition switch off 1 MΩ or higher C28-10 (GCS) or C28-9 (GCSG) - Body ground and other terminals Ignition switch off 1 MΩ or higher -

Connect the inverter with converter assembly connector.

NG

CHECK CONNECTOR CONNECTION CONDITION (GENERATOR RESOLVER CONNECTOR) Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - MOTOR RESOLVER)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the inverter with converter assembly connector.

-

Connect the cable to the negative (-) auxiliary battery terminal.

-

Turn the ignition switch to ON (IG).

-

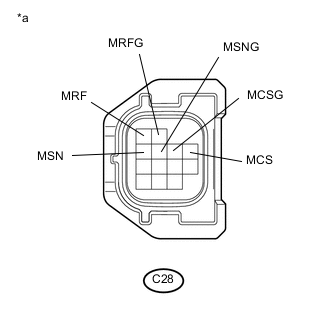

Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition C28-1 (MRF) - Body ground Ignition switch ON (IG) Below 1 V C28-2 (MRFG) - Body ground Ignition switch ON (IG) Below 1 V C28-3 (MSN) - Body ground Ignition switch ON (IG) Below 1 V C28-4 (MSNG) - Body ground Ignition switch ON (IG) Below 1 V C28-6 (MCS) - Body ground Ignition switch ON (IG) Below 1 V C28-5 (MCSG) - Body ground Ignition switch ON (IG) Below 1 V Note

Turning the ignition switch to ON (IG) with the low voltage connector of the inverter with converter assembly disconnected causes other DTCs to be stored. Clear the DTCs after performing this inspection.

-

Turn the ignition switch off.

-

Disconnect the cable from the negative (-) auxiliary battery terminal.

-

Connect the inverter with converter assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK MOTOR RESOLVER

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the inverter with converter assembly connector.

-

Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Switch Condition Specified Condition C28-1 (MRF) - C28-2 (MRFG) Ignition switch off 7.1 to 21.6 Ω C28-3 (MSN) - C28-4 (MSNG) Ignition switch off 13.7 to 34.5 Ω C28-6 (MCS) - C28-5 (MCSG) Ignition switch off 12.8 to 32.4 Ω Standard Resistance (Check for Short) Tester Connection Switch Condition Specified Condition C28-1 (MRF) or C28-2 (MRFG) - Body ground and other terminals Ignition switch off 1 MΩ or higher C28-3 (MSN) or C28-4 (MSNG) - Body ground and other terminals Ignition switch off 1 MΩ or higher C28-6 (MCS) or C28-5 (MCSG) - Body ground and other terminals Ignition switch off 1 MΩ or higher -

Connect the inverter with converter assembly connector.

NG

CHECK CONNECTOR CONNECTION CONDITION (MOTOR RESOLVER CONNECTOR) Click here

OK

-

-

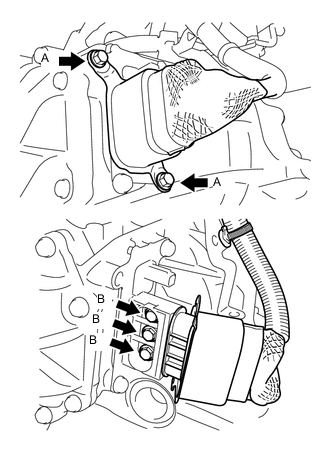

CHECK INVERTER WITH CONVERTER ASSEMBLY (MOTOR CABLE (FOR MG1) CONNECTION CONDITION)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

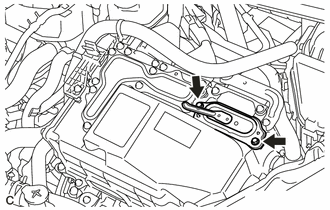

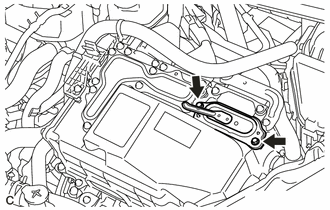

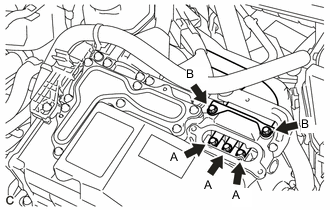

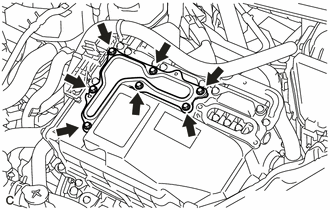

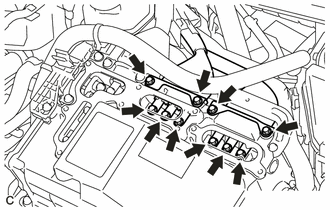

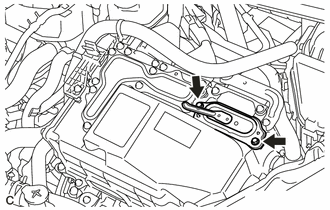

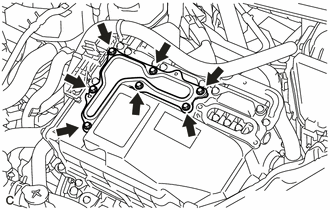

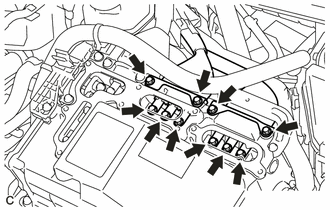

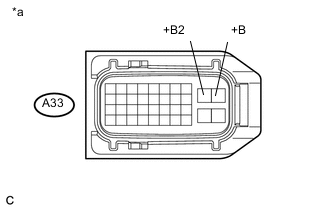

Remove the inverter terminal cover from the inverter with converter assembly.

-

Remove the inverter cover from the inverter with converter assembly.

-

Check that the bolts for the motor cable (for MG1) are tightened to the specified torque, the motor cable (for MG1) is connected securely, and there are no contact problems.

Specified Condition Bolt A T=8.0 N*m (82 kgf*cm, 71 in.*lbf) Bolt B T=9.2 N*m (94 kgf*cm, 81 ft.*lbf) Note

Make sure that the tightening torque of the bolt B is between 6.4 and 12 N*m (65 and 122 kgf*cm, 57 and 106 in.*lbf).

-

Disconnect the motor cable (for MG1) from the inverter with converter assembly.

-

Check for arc marks at the terminals for the motor cable (for MG1).

Result Result Proceed to The terminals are connected securely and there are no contact problems. There are no arc marks. A The terminals are not connected securely and there is a contact problem. There are arc marks. B The terminals are not connected securely and there is a contact problem. There are no arc marks. C The terminals are connected securely and there are no contact problems. There are arc marks. B -

Connect the motor cable (for MG1) to the inverter with converter assembly.

-

Install the inverter cover.

-

Install the inverter terminal cover.

B

REPLACE MALFUNCTIONING PARTS

C

CONNECT SECURELY

A

-

-

CHECK INVERTER WITH CONVERTER ASSEMBLY (MOTOR CABLE (FOR MG2) CONNECTION CONDITION)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

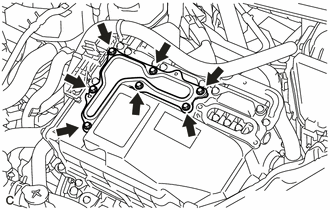

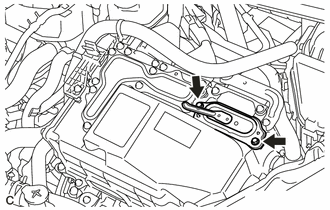

Remove the inverter terminal cover from the inverter with converter assembly.

-

Check that the bolts for the motor cable (for MG2) are tightened to the specified torque, the motor cable (for MG2) is connected securely, and there are no contact problems.

Specified Condition Bolt A T=8.0 N*m (82 kgf*cm, 71 in.*lbf) Bolt B T=9.2 N*m (94 kgf*cm, 81 ft.*lbf) Note

Make sure that the tightening torque of the bolt B is between 6.4 and 12 N*m (65 and 122 kgf*cm, 57 and 106 in.*lbf).

-

Disconnect the motor cable (for MG2) from the inverter with converter assembly.

-

Check for arc marks at the terminals for the motor cable (for MG2).

Result Result Proceed to The terminals are connected securely and there are no contact problems. There are no arc marks. A The terminals are not connected securely and there is a contact problem. There are arc marks. B The terminals are not connected securely and there is a contact problem. There are no arc marks. C The terminals are connected securely and there are no contact problems. There are arc marks. B -

Connect the motor cable (for MG2) to the inverter with converter assembly.

-

Install the inverter terminal cover.

B

REPLACE MALFUNCTIONING PARTS

C

CONNECT SECURELY

A

-

-

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MG1)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the inverter terminal cover from the inverter with converter assembly.

-

Remove the inverter cover from the inverter with converter assembly.

-

Disconnect the motor cable from the inverter with converter assembly.

-

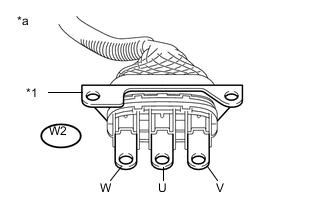

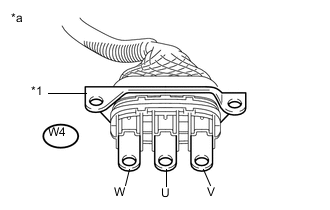

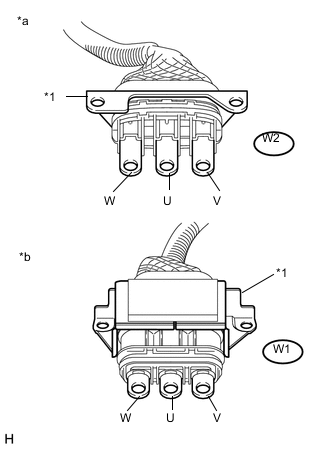

Text in Illustration *1 Shield Ground *a Motor Cable (for MG1)

(Inverter with Converter Assembly Side)

Check MG1 for an interphase short using a milliohmmeter.

-

Using a milliohmmeter, measure the resistance according to the value(s) in the table below.

Tech Tips

If the MG1 temperature is high, the resistance will vary greatly from the specification. Therefore, measure the resistance at least 8 hours after the vehicle is stopped.

Standard Resistance Tester Connection Switch Condition Specified Condition W2-1 (W) - W2-2 (U) Ignition switch off 139.1 to 153.7 mΩ W2-2 (U) - W2-3 (V) Ignition switch off 139.1 to 153.7 mΩ W2-3 (V) - W2-1 (W) Ignition switch off 139.1 to 153.7 mΩ Tech Tips

To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68° F).

-

R20 = Rt / {1 + 0.00393 X (T - 20)}

The calculation is based on the following:

-

R20: Resistance at 20°C (68° F) (mΩ)

-

Rt: Measured resistance (mΩ)

-

T: Temperature when the resistance is measured (°C)

-

-

-

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Switch Condition Specified Condition W2-1 (W) - Body ground and shield ground Ignition switch off 100 MΩ or higher W2-2 (U) - Body ground and shield ground Ignition switch off 100 MΩ or higher W2-3 (V) - Body ground and shield ground Ignition switch off 100 MΩ or higher -

Connect the motor cable.

-

Install the inverter cover.

-

Install the inverter terminal cover.

NG

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MOTOR CABLE (FOR MG1) CONNECTION CONDITION) Click here

OK

-

-

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MG2)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the inverter terminal cover from the inverter with converter assembly.

-

Remove the inverter cover from the inverter with converter assembly.

-

Disconnect the motor cable from the inverter with converter assembly.

-

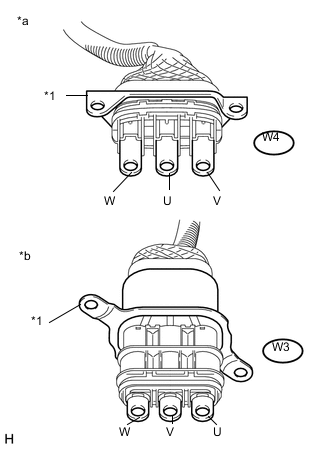

Text in Illustration *1 Shield Ground *a Motor Cable (for MG2)

(Inverter with Converter Assembly Side)

Check MG2 for an interphase short using a milliohmmeter.

-

Using a milliohmmeter, measure the resistance according to the value(s) in the table below.

Tech Tips

If the MG2 temperature is high, the resistance will vary greatly from the specification. Therefore, measure the resistance at least 8 hours after the vehicle is stopped.

Standard Resistance Tester Connection Switch Condition Specified Condition W4-1 (W) - W4-2 (U) Ignition switch off 172.5 to 190.7 mΩ W4-2 (U) - W4-3 (V) Ignition switch off 172.5 to 190.7 mΩ W4-3 (V) - W4-1 (W) Ignition switch off 172.5 to 190.7 mΩ Tech Tips

To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68° F).

-

R20 = Rt / {1 + 0.00393 X (T - 20)}

The calculation is based on the following:

-

R20: Resistance at 20°C (68° F) (mΩ)

-

Rt: Measured resistance (mΩ)

-

T: Temperature when the resistance is measured (°C)

-

-

-

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Switch Condition Specified Condition W4-1 (W) - Body ground and shield ground Ignition switch off 100 MΩ or higher W4-2 (U) - Body ground and shield ground Ignition switch off 100 MΩ or higher W4-3 (V) - Body ground and shield ground Ignition switch off 100 MΩ or higher -

Connect the motor cable.

-

Install the inverter cover.

-

Install the inverter terminal cover.

NG

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MOTOR CABLE (FOR MG2) CONNECTION CONDITION) Click here

OK

-

-

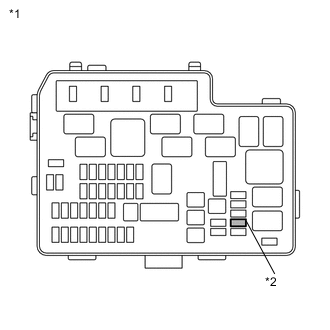

CHECK FUSE (PCU)

-

Text in Illustration *1 No. 2 Engine Room Relay Block *2 PCU fuse Remove the PCU fuse from the No. 2 engine room relay block.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition PCU fuse terminal Always Below 1Ω -

Install the PCU fuse.

NG

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - PCU FUSE) Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY POWER SOURCE CIRCUIT)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the inverter with converter assembly connector.

-

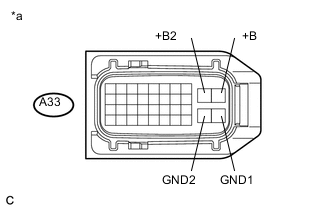

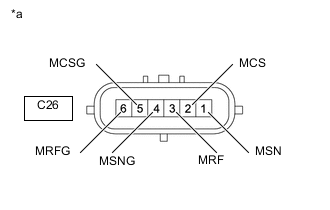

Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition A33-28 (GND1) - Body ground Ignition switch off Below 1 Ω A33-27 (GND2) - Body ground Ignition switch off Below 1 Ω -

Connect the cable to the negative (-) auxiliary battery terminal.

-

Turn the ignition switch to ON (IG).

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition A33-10 (+B) - Body ground Ignition switch ON (IG) Same as auxiliary battery voltage A33-9 (+B2) - Body ground Ignition switch ON (IG) Same as auxiliary battery voltage Note

Turning the ignition switch to ON (IG) with the inverter with converter assembly connector disconnected causes other DTCs to be stored. Clear the DTCs after performing this inspection.

-

Turn the ignition switch off.

-

Disconnect the cable from the negative (-) auxiliary battery terminal.

-

Connect the inverter with converter assembly connector.

NG

REPAIR OR REPLACE POWER SOURCE CIRCUIT

OK

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - HYBRID VEHICLE CONTROL ECU)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the inverter with converter assembly connector.

-

Disconnect the hybrid vehicle control ECU connector.

-

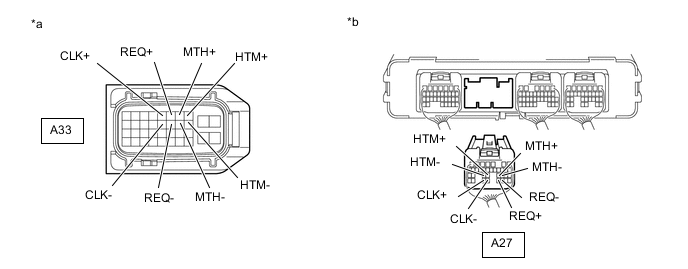

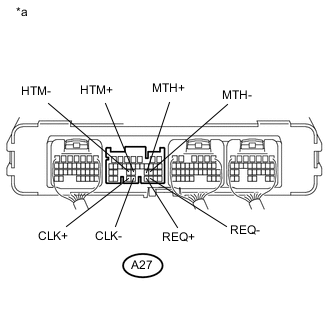

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Switch Condition Specified Condition A33-8 (HTM+) - A27-24 (HTM+) Ignition switch off Below 1 Ω A33-18 (HTM-) - A27-25 (HTM-) Ignition switch off Below 1 Ω A33-7 (MTH+) - A27-23 (MTH+) Ignition switch off Below 1 Ω A33-17 (MTH-) - A27-22 (MTH-) Ignition switch off Below 1 Ω A33-6 (REQ+) - A27-31 (REQ+) Ignition switch off Below 1 Ω A33-16 (REQ-) - A27-30 (REQ-) Ignition switch off Below 1 Ω A33-5 (CLK+) - A27-33 (CLK+) Ignition switch off Below 1 Ω A33-15 (CLK-) - A27-32 (CLK-) Ignition switch off Below 1 Ω Standard Resistance (Check for Short) Tester Connection Switch Condition Specified Condition A33-8 (HTM+) or A27-24 (HTM+) - Body ground and other terminals Ignition switch off 10 kΩ or higher A33-18 (HTM-) or A27-25 (HTM-) - Body ground and other terminals Ignition switch off 10 kΩ or higher A33-7 (MTH+) or A27-23 (MTH+) - Body ground and other terminals Ignition switch off 10 kΩ or higher A33-17 (MTH-) or A27-22 (MTH-) - Body ground and other terminals Ignition switch off 10 kΩ or higher A33-6 (REQ+) or A27-31 (REQ+) - Body ground and other terminals Ignition switch off 10 kΩ or higher A33-16 (REQ-) or A27-30 (REQ-) - Body ground and other terminals Ignition switch off 10 kΩ or higher A33-5 (CLK+) or A27-33 (CLK+) - Body ground and other terminals Ignition switch off 10 kΩ or higher A33-15 (CLK-) or A27-32 (CLK-) - Body ground and other terminals Ignition switch off 10 kΩ or higher Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

*b Rear view of wire harness connector

(to Hybrid Vehicle Control ECU)

-

Connect the cable to the negative (-) auxiliary battery terminal.

-

Turn the ignition switch to ON (IG).

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition A33-8 (HTM+) or A27-24 (HTM+) - Body ground Ignition switch ON (IG) Below 1 V A33-18 (HTM-) or A27-25 (HTM-) - Body ground Ignition switch ON (IG) Below 1 V A33-7 (MTH+) or A27-23 (MTH+) - Body ground Ignition switch ON (IG) Below 1 V A33-17 (MTH-) or A27-22 (MTH-) - Body ground Ignition switch ON (IG) Below 1 V A33-6 (REQ+) or A27-31 (REQ+) - Body ground Ignition switch ON (IG) Below 1 V A33-16 (REQ-) or A27-30 (REQ-) - Body ground Ignition switch ON (IG) Below 1 V A33-5 (CLK+) or A27-33 (CLK+) - Body ground Ignition switch ON (IG) Below 1 V A33-15 (CLK-) or A27-32 (CLK-) - Body ground Ignition switch ON (IG) Below 1 V Note

Turning the ignition switch to ON (IG) with the hybrid vehicle control ECU and inverter with converter assembly connector disconnected causes other DTCs to be stored. Clear the DTCs after performing this inspection.

-

Turn the ignition switch off.

-

Disconnect the cable from the negative (-) auxiliary battery terminal.

-

Connect the hybrid vehicle control ECU connector.

-

Connect the inverter with converter assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

-

-

CHECK HYBRID VEHICLE CONTROL ECU

-

Disconnect the hybrid vehicle control ECU connector.

-

Text in Illustration *a Component without harness connected

(Hybrid Vehicle Control ECU)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition A27-24 (HTM+) - A27-25 (HTM-) Ignition switch off 80 to 170 Ω A27-23 (MTH+) - A27-22 (MTH-) Ignition switch off 80 to 170 Ω A27-31 (REQ+) - A27-30 (REQ-) Ignition switch off 80 to 170 Ω A27-33 (CLK+) - A27-31 (CLK-) Ignition switch off 80 to 170 Ω -

Connect the hybrid vehicle control ECU connector.

NG

REPLACE HYBRID VEHICLE CONTROL ECU Click here

OK

-

-

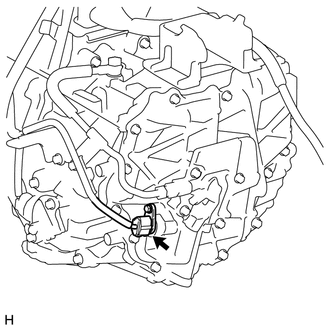

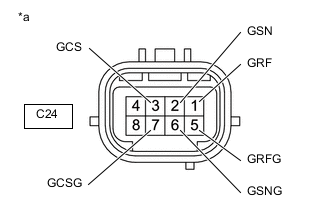

CHECK CONNECTOR CONNECTION CONDITION (GENERATOR RESOLVER CONNECTOR)

-

Check the connection of the generator resolver connector.

OK The connector is connected securely and there are no contact problems.

NG

CONNECT SECURELY

OK

-

-

CHECK CONNECTOR CONNECTION CONDITION (MOTOR RESOLVER CONNECTOR)

-

Check the connection of the motor resolver connector.

OK The connector is connected securely and there are no contact problems.

OK

REFER TO REPLACE INVERTER WITH CONVERTER ASSEMBLY PARTS Click here

NG

CONNECT SECURELY

-

-

CHECK CONNECTOR CONNECTION CONDITION (GENERATOR RESOLVER CONNECTOR)

-

Check the connection of the generator resolver connector.

OK The connector is connected securely and there are no contact problems.

NG

CONNECT SECURELY

OK

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - GENERATOR RESOLVER)

-

Disconnect the resolver connector.

-

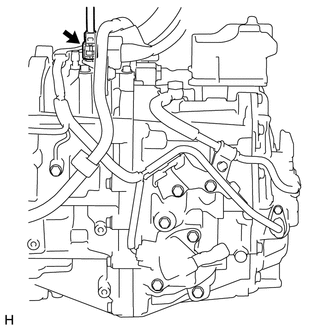

*a Component without harness connected

(Generator resolver (Hybrid Vehicle Transaxle Assembly))

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Condition Specified Condition C24-1 (GRF) - C24-5 (GRFG) Ignition switch off 9.5 to 15.5 Ω C24-2 (GSN) - C24-6 (GSNG) Ignition switch off 15.0 to 27.0 Ω C24-3 (GCS) - C24-7 (GCSG) Ignition switch off 14.0 to 26.0 Ω Tech Tips

To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68°F).

R20 = Rt / {1 + 0.00393 X (T - 20)}

The calculation is based on the following:

R20: Resistance at 20°C (68°F) (mΩ)

Rt: Measured resistance (mΩ)

T: Temperature when the resistance is measured (°C (°F).)

Standard Resistance (Check for Short) Tester Connection Condition Specified Condition C24-1 (GRF) - Body ground and other terminals (except C24-5 (GRFG)) Power switch off 1 MΩ or higher C24-5 (GRFG) - Body ground and other terminals (except C24-1 (GRF)) Power switch off 1 MΩ or higher C24-2 (GSN) - Body ground and other terminals (except C24-6 (GSNG)) Power switch off 1 MΩ or higher C24-6 (GSNG) - Body ground and other terminals (except C24-2 (GSN)) Power switch off 1 MΩ or higher C24-3 (GCS) - Body ground and other terminals (except C24-7 (GCSG)) Power switch off 1 MΩ or higher C24-7 (GCSG) - Body ground and other terminals (except C24-3 (GCS)) Power switch off 1 MΩ or higher -

Reconnect the resolver connector.

OK

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

-

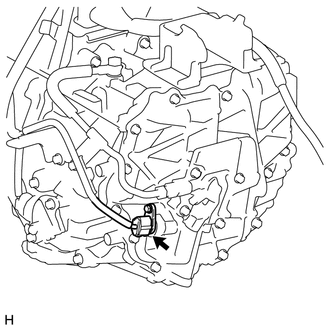

CHECK CONNECTOR CONNECTION CONDITION (MOTOR RESOLVER CONNECTOR)

-

Check the connection of the motor resolver connector.

OK The connector is connected securely and there are no contact problems.

NG

CONNECT SECURELY

OK

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - MOTOR RESOLVER)

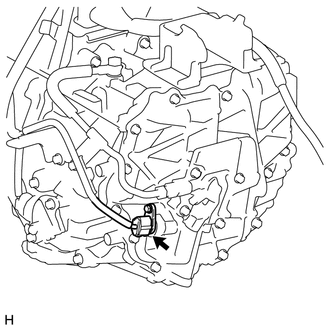

-

Disconnect the resolver connector.

-

*a Component without harness connected

(Motor Resolver (Hybrid Vehicle Transaxle Assembly))

Measure the resistance according to the value(s) in the table below.

Standard Resistance (Check for Open) Tester Connection Condition Specified Condition C26-3 (MRF) - C26-6 (MRFG) Ignition switch off 9.5 to 15.5 Ω C26-1 (MSN) - C26-4 (MSNG) Ignition switch off 15.0 to 27.0 Ω C26-2 (MCS) - C26-5 (MCSG) Ignition switch off 14.0 to 26.0 Ω Tech Tips

To correct the variation of the measured resistance due to temperature, use the following formula to calculate the resistance at 20°C (68°F).

R20 = Rt / {1 + 0.00393 X (T - 20)}

The calculation is based on the following:

R20: Resistance at 20°C (68°F) (mΩ)

Rt: Measured resistance (mΩ)

T: Temperature when the resistance is measured (°C (°F).)

Standard Resistance (Check for Short) Tester Connection Condition Specified Condition C26-3 (MRF) - Body ground and other terminals (except C26-6 (MRFG)) Power switch off 1 MΩ or higher C26-6 (MRFG) - Body ground and other terminals (except C26-3 (MRF)) Power switch off 1 MΩ or higher C26-1 (MSN) - Body ground and other terminals (except C26-4 (MSNG)) Power switch off 1 MΩ or higher C26-4 (MSNG) - Body ground and other terminals (except C26-1 (MSN)) Power switch off 1 MΩ or higher C26-2 (MCS) - Body ground and other terminals (except C26-5 (MCSG)) Power switch off 1 MΩ or higher C26-5 (MCSG) - Body ground and other terminals (except C26-2 (MCS)) Power switch off 1 MΩ or higher -

Reconnect the resolver connector.

OK

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

-

CHECK HARNESS AND CONNECTOR (INVERTER WITH CONVERTER ASSEMBLY - PCU FUSE)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the inverter with converter assembly connector.

-

Text in Illustration *a Front view of wire harness connector

(to Inverter with Converter Assembly)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition A33-10 (+B) - Body ground Ignition switch off 10 kΩ or higher A33-9 (+B2) - Body ground Ignition switch off 10 kΩ or higher -

Connect the inverter with converter assembly connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR Click here

OK

-

-

REFER TO REPLACE INVERTER WITH CONVERTER ASSEMBLY PARTS

NEXT

REPLACE FUSE (PCU)

-

REPAIR OR REPLACE HARNESS OR CONNECTOR

NEXT

REPLACE FUSE (PCU)

-

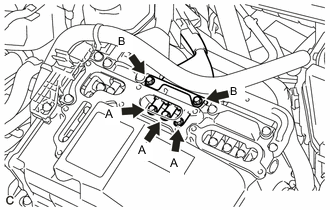

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MOTOR CABLE (FOR MG1) CONNECTION CONDITION)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the inverter with converter assembly Click here.

-

Check that the bolts for the motor cable (for MG1) are tightened to the specified torque, the motor cable (for MG1) is connected securely, and there are no contact problems.

Specified Condition Bolt A T=19.5 N*m (199 kgf*cm, 14 ft.*lbf) Bolt B T=10 N*m (102 kgf*cm, 7 ft.*lbf) Note

-

Make sure that the tightening torque of the bolt A is between 13.5 and 25 N*m (138 and 255 kgf*cm, 10 and 18 ft.*lbf).

-

Make sure that the tightening torque of the bolt B is between 8 and 12 N*m (82 and 122 kgf*cm, 71 and 106 in.*lbf).

-

-

Disconnect the motor cable (for MG1) from the hybrid vehicle transaxle assembly.

-

Check for arc marks at the terminals for the motor cable (for MG1).

Result Result Proceed to The terminals are connected securely and there are no contact problems. There are no arc marks. A The terminals are not connected securely and there is a contact problem. There are arc marks. B The terminals are not connected securely and there is a contact problem. There are no arc marks. C The terminals are connected securely and there are no contact problems. There are arc marks. B -

Connect the motor cable (for MG1) to the hybrid vehicle transaxle assembly.

-

Install the inverter with converter assembly.

B

REPLACE MALFUNCTIONING PARTS

C

CONNECT SECURELY

A

-

-

CHECK MOTOR CABLE (FOR MG1)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the motor cable Click here.

-

Text in Illustration *1 Shield ground *a Motor Cable (for MG1)

(Inverter with Converter Assembly Side)

*b Motor Cable (for MG1)

(Hybrid Vehicle Transaxle Assembly Side)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Switch Condition Specified Condition W2-1 (W) - Body ground and shield ground Ignition switch off 100 MΩ or higher W2-2 (U) - Body ground and shield ground Ignition switch off 100 MΩ or higher W2-3 (V) - Body ground and shield ground Ignition switch off 100 MΩ or higher Note

Wrap the terminal of the motor cable (for MG1) with insulating tape to prevent them from coming into contact with body ground

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition W2-1 (W) - W1-1 (W) Ignition switch off Below 1 Ω W2-2 (U) - W1-2 (U) Ignition switch off Below 1 Ω W2-3 (V) - W1-3 (V) Ignition switch off Below 1 Ω W2-1 (W) - W1-2 (U) Ignition switch off 100 MΩ or higher W2-2 (U) - W1-3 (V) Ignition switch off 100 MΩ or higher W2-3 (V) - W1-1 (W) Ignition switch off 100 MΩ or higher -

Install the motor cable.

OK

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

NG

REPLACE MOTOR CABLE Click here

-

-

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MOTOR CABLE (FOR MG2) CONNECTION CONDITION)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Check that the bolts for the motor cable (for MG2) are tightened to the specified torque, the motor cable (for MG2) is connected securely, and there are no contact problems.

Specified Condition Bolt A T=19.5 N*m (199 kgf*cm, 14 ft.*lbf) Bolt B T=10 N*m (102 kgf*cm, 7 ft.*lbf) Note

-

Make sure that the tightening torque of the bolt A is between 13.5 and 25 N*m (138 and 255 kgf*cm, 10 and 18 ft.*lbf).

-

Make sure that the tightening torque of the bolt B is between 8 and 12 N*m (82 and 122 kgf*cm, 71 and 106 in.*lbf).

-

-

Disconnect the motor cable (for MG2) from the hybrid vehicle transaxle assembly.

-

Check for arc marks at the terminals for the motor cable (for MG2).

Result Result Proceed to The terminals are connected securely and there are no contact problems. There are no arc marks. A The terminals are not connected securely and there is a contact problem. There are arc marks. B The terminals are not connected securely and there is a contact problem. There are no arc marks. C The terminals are connected securely and there are no contact problems. There are arc marks. B -

Connect the motor cable (for MG2) to the hybrid vehicle transaxle assembly.

B

REPLACE MALFUNCTIONING PARTS

C

CONNECT SECURELY

A

-

-

CHECK MOTOR CABLE (FOR MG2)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the ignition switch to ON (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the motor cable Click here.

-

Text in Illustration *1 Shield ground *a Motor Cable (for MG2)

(Inverter with Converter Assembly Side)

*b Motor Cable (for MG2)

(Hybrid Vehicle Transaxle Assembly Side)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Switch Condition Specified Condition W4-1 (W) - Body ground and shield ground Ignition switch off 100 MΩ or higher W4-2 (U) - Body ground and shield ground Ignition switch off 100 MΩ or higher W4-3 (V) - Body ground and shield ground Ignition switch off 100 MΩ or higher Note

Wrap the terminal of the motor cable (for MG2) with insulating tape to prevent them from coming into contact with body ground

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition W4-1 (W) - W3-1 (W) Ignition switch off Below 1 Ω W4-2 (U) - W3-3 (U) Ignition switch off Below 1 Ω W4-3 (V) - W3-2 (V) Ignition switch off Below 1 Ω W4-1 (W) - W3-3 (U) Ignition switch off 100 MΩ or higher W4-2 (U) - W3-2 (V) Ignition switch off 100 MΩ or higher W4-3 (V) - W3-1 (W) Ignition switch off 100 MΩ or higher -

Install the motor cable.

OK

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

NG

REPLACE MOTOR CABLE Click here

-

-

REPLACE HV COOLANT

-

Replace the HV coolant with coolant having an appropriate concentration (appropriate freeze point) for the vehicle usage conditions Click here.

NEXT

COMPLETED

-