FRONT DRIVE SHAFT ASSEMBLY INSTALLATION

-

INSTALL FRONT DRIVE SHAFT ASSEMBLY LH

-

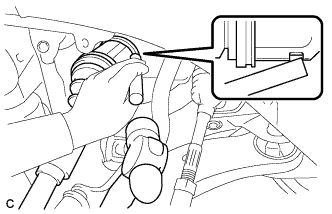

Align the shaft splines and install the drive shaft assembly LH with a brass bar and a hammer.

Note

-

Set the shaft snap ring with the opening facing down.

-

Be careful not to damage the drive shaft dust cover, boot or oil seal.

-

When inserting the drive shaft assembly, keep it level.

-

-

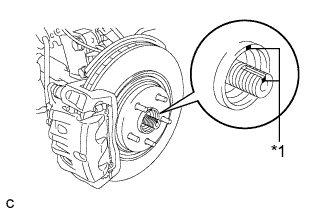

Text in Illustration *1 Matchmark Align the matchmarks and install the front drive shaft assembly LH to the front axle hub sub-assembly.

-

-

INSTALL FRONT DRIVE SHAFT ASSEMBLY RH

-

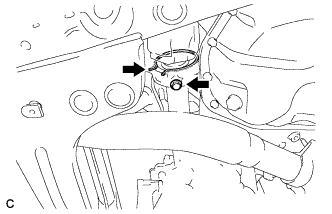

Install the front drive shaft assembly RH.

-

Install a new bearing bracket hole snap ring and the bolt.

- Torque:

- 32 N*m { 330 kgf*cm, 24 ft.*lbf }

Note

-

Do not damage the boot or oil seal.

-

When inserting the drive shaft assembly, keep it level.

-

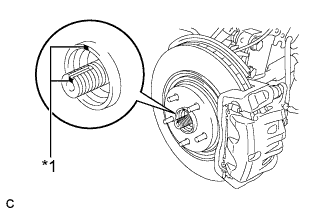

Text in Illustration *1 Matchmark Align the matchmarks and install the front drive shaft assembly RH to the front axle hub sub-assembly.

-

-

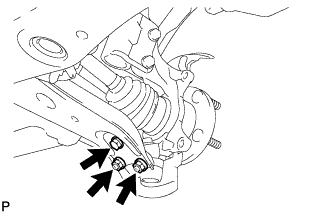

INSTALL NO. 1 FRONT SUSPENSION LOWER ARM

-

Install the front lower suspension arm to the front lower ball joint with the bolt and 2 nuts.

- Torque:

- 92 N*m { 938 kgf*cm, 68 ft.*lbf }

-

-

INSTALL TIE ROD ASSEMBLY

-

Connect the tie rod assembly LH to the steering knuckle with the nut.

- Torque:

- 49 N*m { 500 kgf*cm, 36 ft.*lbf }

-

Install a new cotter pin.

Note

Further tighten the nut up to 60° if the holes for the cotter pin are not aligned.

-

-

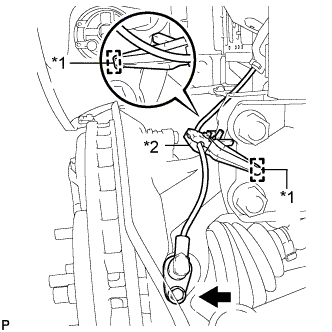

INSTALL FRONT SPEED SENSOR

-

Text in Illustration *1 Hole *2 Resin Clamp Install the resin clamp and front speed sensor with the bolt.

- Torque:

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

Note

-

Prevent foreign matter from attaching to the sensor tip.

-

Firmly insert the sensor body into the knuckle before tightening the bolt.

-

After installing the sensor to the knuckle, make sure that there is no clearance between the sensor stay and knuckle. Also make sure that no foreign matter is stuck between the parts.

-

To prevent interference between the sensor and magnetic rotor, do not rotate the sensor body during or after the insertion of the sensor body to the knuckle.

-

-

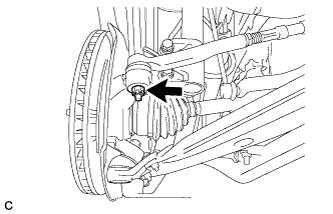

INSTALL FRONT STABILIZER LINK ASSEMBLY

-

Install the front stabilizer link assembly to the front shock absorber with the nut.

- Torque:

- 74 N*m { 755 kgf*cm, 55 ft.*lbf }

Tech Tips

If the ball joint turns together with the nut, use a hexagon wrench (6 mm) to hold the stud bolt.

-

-

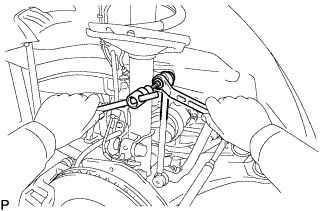

INSTALL FRONT AXLE SHAFT NUT

-

Clean the threaded parts on the drive shaft and a new axle shaft nut using a non-residue solvent.

Tech Tips

-

Be sure to perform this work for a new drive shaft.

-

Keep the threaded parts free of oil and foreign objects.

-

-

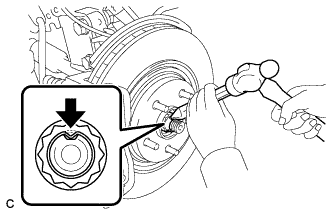

Using a socket wrench (30 mm), install the axle shaft nut.

- Torque:

- 294 N*m { 2998 kgf*cm, 217 ft.*lbf }

-

Using a chisel and hammer, stake the front axle shaft nut.

-

-

INSTALL FRONT WHEELS

- Torque:

- 103 N*m { 1050 kgf*cm, 76 ft.*lbf }

-

ADD HYBRID TRANSAXLE FLUID

-

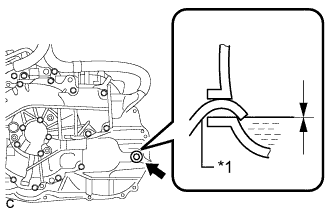

Text in Illustration *1 Filler Nozzle Add transaxle fluid until the transaxle fluid level is between 0 mm (0 in.) from the bottom lip of the filler plug opening.

Note

-

Keep the oil temperature at 5°C (41°F) or higher.

-

Stop the vehicle on a flat road.

-

Recheck the transaxle fluid level after driving following transaxle fluid replacement.

-

Insufficient or excessive amounts of transaxle fluid may be the cause of some trouble.

-

Be sure to add fluid slowly. If fluid is added quickly, the fluid may hit internal parts and bounce back, resulting in fluid coming out of the filler plug opening.

-

Be sure to fully insert the filler nozzle into the filler plug opening.

-

-

Using a hexagon socket wrench 10 mm, temporarily tighten the filler plug and gasket.

-

-

INSPECT AND ADJUST HYBRID TRANSAXLE FLUID

-

Set the vehicle to FWD inspection mode Click here.

-

After waiting for 1 minute or more, stop the engine.

-

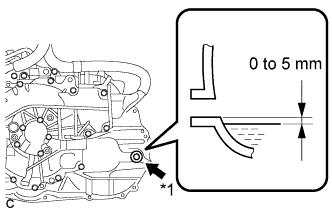

Text in Illustration *1 Filler Plug Using a hexagon socket wrench 10 mm, remove the filler plug and gasket.

-

Add transaxle fluid until the transaxle fluid level is between 0 and 5 mm (0 and 0.197 in.) from the bottom lip of the filler plug opening.

Note

-

Keep the transaxle fluid temperature at 5°C (41°F) or higher.

-

Stop the vehicle on a flat road.

-

Recheck the transaxle fluid level after driving following transaxle fluid replacement.

-

Insufficient or excessive amounts of transaxle fluid may be the cause of some trouble.

-

Be sure to add fluid slowly. If fluid is added quickly, the fluid may hit internal parts and bounce back, resulting in fluid coming out of the filler plug opening.

-

Be sure to directly check that the transaxle fluid level is within the specified range.

-

-

After adding fluid, leave it for 30 seconds so that the fluid surface can become still again, and then check that the fluid level is between 0 to 5 mm (0 to 0.197 in.) from the bottom lip of the filler plug opening. (If the fluid is insufficient, return to the Add Hybrid Transaxle Fluid procedure.)

-

Check for leaks if the quantity of transaxle fluid is low.

-

Using a hexagon socket wrench 10 mm, install the filler plug and a new gasket.

- Torque:

- 39 N*m { 398 kgf*cm, 29 ft.*lbf }

-

-

ADJUST FRONT WHEEL ALIGNMENT

Tech Tips

-

CHECK SPEED SENSOR SIGNAL

Tech Tips