СИСТЕМА ECD, Diagnostic DTC:P0112, P0113

| DTC Code | DTC Name |

|---|---|

| P0112 | Intake Air Temperature Circuit Low Input |

| P0113 | Intake Air Temperature Circuit High Input |

DESCRIPTION

The intake air temperature sensor is built into the Mass Air Flow (MAF) meter and senses the intake air temperature.

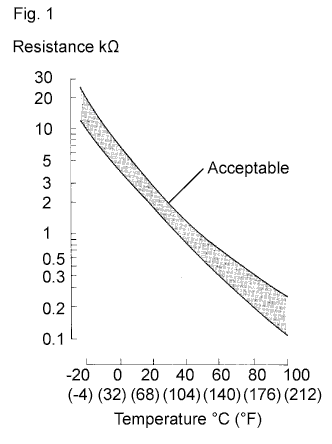

A thermistor built into the sensor changes its resistance value according to the intake air temperature.

The lower the intake air temperature, the greater the thermistor resistance value. The higher the intake air temperature, the lower the thermistor resistance value (See Fig. 1).

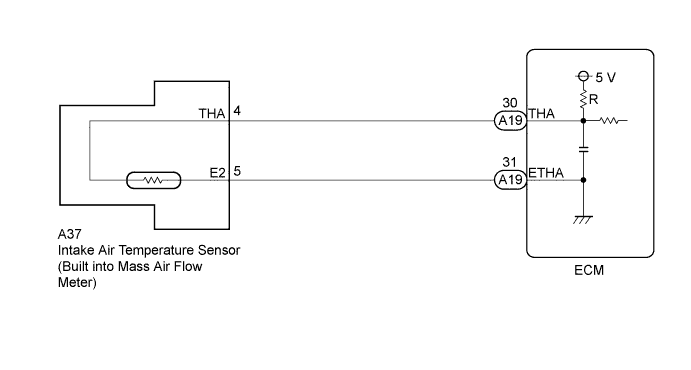

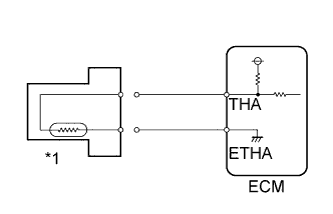

The intake air temperature sensor is connected to the ECM. The 5 V power source voltage in the ECM is applied to the intake air temperature sensor from terminal THA via resistor R. Resistor R and the intake air temperature sensor are connected in series. When the resistance value of the intake air temperature sensor changes in accordance with changes in the intake air temperature, the potential at terminal THA also changes. Based on this signal, the ECM increases the fuel injection volume to improve drivability with a cold engine.

Tech Tips

When the intake air temperature sensor output is outside the normal range, the ECM determines that this is a malfunction.

| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

|---|---|---|

| Engine idles for approximately 15 seconds | Intake air temperature sensor output is more than 140°C (284°F). (2 trip detection logic) |

|

| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

|---|---|---|

| Engine idles for approximately 15 seconds | Intake air temperature sensor output is less than -40°C (-40°F). (2 trip detection logic) |

|

| DTC No. | Data List |

|---|---|

| P0112 |

|

| P0113 |

Tech Tips

-

If DTC P0112 or P0113 is stored, the following symptoms may appear:

-

Misfire

-

Combustion noise

-

Black smoke

-

White smoke

-

Lack of power

-

When DTC P0112 or P0113 is stored, check the intake air temperature by entering the following menus on the intelligent tester: Powertrain / Engine and ECT / Data List / Intake Air.

| Temperature Displayed | Malfunction |

|---|---|

| -40°C (-40°F) | Open circuit |

| 140°C (284°F) | Short circuit |

WIRING DIAGRAM

INSPECTION PROCEDURE

Tech Tips

-

When the ECM must be replaced, before replacing the ECM, perform the "Learning Values Save" function using the intelligent tester. Then after installing the new ECM, perform all of the initializations/registrations for the "Learning Values Write" function by following the instructions shown on the tester display.

-

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

PROCEDURE

-

READ VALUE USING INTELLIGENT TESTER (INTAKE AIR)

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Intake Air.

-

Read the value.

OK Same as actual intake air temperature. Result Result Proceed to -40°C (-40°F) A 140°C (284°F) or higher B Same as actual intake air temperature C Tech Tips

-

If there is an open circuit, the intelligent tester indicates -40°C (-40°F).

-

If there is a short circuit, the intelligent tester indicates 140°C (284°F) or higher.

-

B

READ VALUE USING INTELLIGENT TESTER (CHECK FOR SHORT IN WIRE HARNESS) Click here

C

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

A

-

-

READ VALUE USING INTELLIGENT TESTER (CHECK FOR OPEN IN WIRE HARNESS)

-

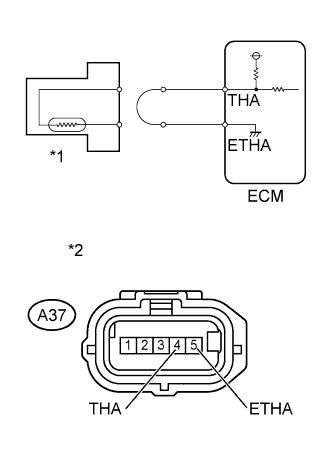

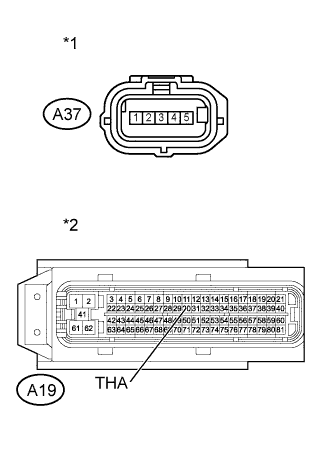

Text in Illustration *1 Mass Air Flow Meter *2 Front view of wire harness connector

(to Mass Air Flow Meter)

Disconnect the mass air flow meter connector.

-

Connect terminals THA and E2 of the mass air flow meter wire harness side connector.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the tester on.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Intake Air.

-

Read the value.

Standard 140°C (284°F) or higher -

Reconnect the mass air flow meter connector.

OK

CONFIRM GOOD CONNECTION TO SENSOR. IF OK, REPLACE MASS AIR FLOW METER Click here

NG

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM) Click here

-

-

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

-

Disconnect the mass air flow meter connector.

-

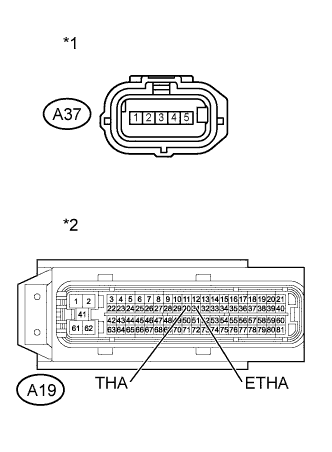

Text in Illustration *1 Front view of wire harness connector

(to MASS Air Flow Meter)

*2 Front view of wire harness connector

(to ECM)

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A37-4 - A19-30 (THA) Always Below 1 Ω A37-5 - A19-31 (ETHA) Always Below 1 Ω -

Reconnect the mass air flow meter connector.

-

Reconnect the ECM connector.

OK

CONFIRM GOOD CONNECTION TO ECM. IF OK, REPLACE ECM Click here

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR Click here

-

-

READ VALUE USING INTELLIGENT TESTER (CHECK FOR SHORT IN WIRE HARNESS)

-

Disconnect the mass air flow meter connector.

-

Text in Illustration *1 Mass Air Flow Meter Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the tester on.

-

Reconnect the mass air flow meter connector.

-

Enter the following menus: Powertrain / Engine and ECT / Data List / Intake Air.

-

Read the value.

Standard -40°C (-40°F) -

Reconnect the mass air flow meter connector.

OK

REPLACE MASS AIR FLOW METER Click here

NG

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM) Click here

-

-

CHECK HARNESS AND CONNECTOR (MASS AIR FLOW METER - ECM)

-

Disconnect the mass air flow meter connector.

-

Text in Illustration *1 Front view of wire harness connector

(to Mass Air Flow Meter)

*2 Front view of wire harness connector

(to ECM)

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A37-4 or A19-30 (THA) - Body ground Always 10 kΩ or higher -

Reconnect the mass air flow meter connector.

-

Reconnect the ECM connector.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR Click here

OK

-

-

REPLACE ECM

-

Replace the ECM Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

CONFIRM GOOD CONNECTION TO SENSOR. IF OK, REPLACE MASS AIR FLOW METER

-

Replace the mass air flow meter Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPAIR OR REPLACE HARNESS OR CONNECTOR

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

CONFIRM GOOD CONNECTION TO ECM. IF OK, REPLACE ECM

-

Replace the ECM Click here.

NEXT

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED Click here

-

-

REPLACE MASS AIR FLOW METER

-

Replace the mass air flow meter Click here.

NEXT

-

-

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

-

Connect the intelligent tester to the DLC3.

-

Clear the DTCs Click here.

-

Start the engine.

-

Allow the engine to idle for 15 seconds or more.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Confirm that the DTC is not output again.

NEXT

END

-