FUEL INJECTOR INSTALLATION

Note

-

When replacing the injectors (including shuffling the injectors between the cylinders), common rail, intake manifold or cylinder head, it is necessary to replace the injection pipes with new ones.

-

When replacing the fuel supply pump, common rail, intake manifold or cylinder head, it is necessary to replace the fuel inlet pipe with a new one.

-

INSTALL INJECTOR ASSEMBLY

Note

Before installing the injector, check for carbon, foreign matter, etc. on the seal surfaces of the cylinder head and injector. If there is foreign matter, remove it before installing the injector.

-

Install 4 new nozzle seats to the cylinder head.

-

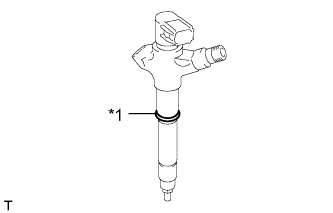

Text in Illustration *1 New O-Ring Install a new O-ring to each injector.

-

Apply a light coat of engine oil to the O-ring on each injector.

-

Install the 4 injectors to the cylinder head.

Note

Fit the injectors to the nozzle seats.

-

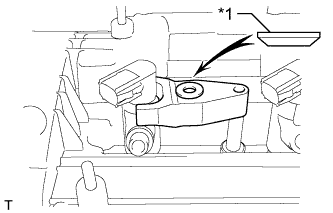

Text in Illustration *1 Washer Install the nozzle holder clamps and washers as shown in the illustration.

Note

Pay attention to the mounting orientation (beveled edge) of the washer.

-

Temporarily install the nozzle holder clamp bolts.

Note

When temporarily installing the nozzle holder clamp bolt to the nozzle holder clamp, make sure that the bolt and clamp are not at an angle.

Tech Tips

Apply a light coat of engine oil to the threads of the nozzle holder clamp bolts.

-

Temporarily install the 4 injection pipes.

-

Temporarily install the No. 1 leakage pipe and 4 new gaskets with the 4 union bolts and bolt.

-

Tighten the 4 nozzle holder clamp bolts.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

-

-

INSTALL NO. 1 NOZZLE LEAKAGE PIPE

-

Tighten the 4 union bolts.

- Torque:

- 18 N*m { 184 kgf*cm, 13 ft.*lbf }

-

Tighten the bolt.

- Torque:

- 21 N*m { 209 kgf*cm, 15 ft.*lbf }

-

-

INSTALL INJECTION PIPE SUB-ASSEMBLY

-

Using a 14 mm union nut wrench, tighten the 4 nuts at the common rail end of the injection pipes.

- Torque:

- 30 N*m { 306 kgf*cm, 22 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

Using a 14 mm union nut wrench, tighten the 4 nuts at the injector end of the injection pipes.

- Torque:

- 30 N*m { 306 kgf*cm, 22 ft.*lbf }

Note

Use the formula to calculate special torque values for situations where a union nut wrench is combined with a torque wrench Click here.

-

Install the 4 injection pipe clamps with the 2 bolts.

- Torque:

- 5.0 N*m { 51 kgf*cm, 44 in.*lbf }

-

-

INSTALL NO. 2 NOZZLE LEAKAGE PIPE

-

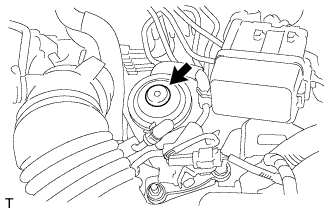

Temporarily install the No. 2 nozzle leakage pipe and a new gasket with the check valve and bolt.

-

Tighten the check valve.

- Torque:

- 32 N*m { 321 kgf*cm, 23 ft.*lbf }

-

Tighten the bolt.

- Torque:

- 32 N*m { 321 kgf*cm, 23 ft.*lbf }

-

Using pliers, grip the claws of the 3 clips and slide the 3 clips to connect the 3 fuel hoses.

-

-

INSTALL FUEL TUBE SUB-ASSEMBLY

-

Temporarily install the fuel tube and 2 new gaskets with the check valve and union bolt.

-

Tighten the check valve.

- Torque:

- 32 N*m { 321 kgf*cm, 23 ft.*lbf }

-

Tighten the union bolt.

- Torque:

- 23 N*m { 235 kgf*cm, 17 ft.*lbf }

-

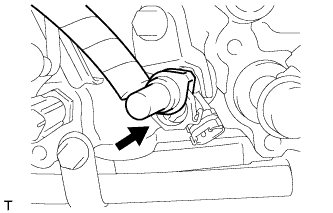

Connect the fuel tube connector to the injector.

-

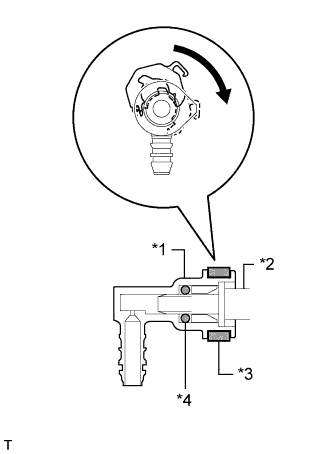

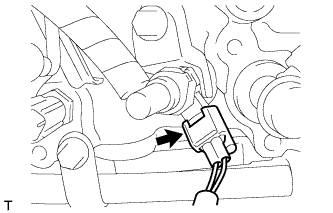

Text in Illustration *1 Fuel Tube Connector *2 Injector *3 Retainer *4 O-Ring Turn the retainer in the direction indicated by the arrow until it makes a "click" sound.

Note

If the fuel tube connector is not inserted to the correct position on the injector, the retainer cannot be turned far enough in the direction of the arrow.

-

Connect the exhaust fuel addition injector connector.

-

-

INSTALL FUEL HOSE PROTECTOR

-

Install the fuel hose protector with the bolt.

- Torque:

- 21 N*m { 209 kgf*cm, 15 ft.*lbf }

-

-

CONNECT ENGINE WIRE

-

Connect the engine wire with the bolt and 3 nuts.

- Torque:

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

-

Install the wire harness bracket with the bolt.

- Torque:

- 13 N*m { 133 kgf*cm, 10 ft.*lbf }

-

Attach the 2 wire harness clamps.

-

Connect the glow plug wire harness and install the nut and screw grommet.

- Torque:

- 4.0 N*m { 41 kgf*cm, 35 in.*lbf }

-

Connect the pressure discharge valve connector.

-

Connect the fuel pressure sensor connector.

-

-

INSTALL AIR CLEANER CASE SUB-ASSEMBLY

-

Install the air cleaner case with the 3 bolts.

- Torque:

- 7.0 N*m { 71 kgf*cm, 62 in.*lbf }

-

-

INSTALL AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

-

INSTALL AIR CLEANER CAP SUB-ASSEMBLY

-

Connect the air cleaner hose.

-

Attach the 4 clamps to install the air cleaner cap.

-

Connect the No. 2 ventilation hose.

-

Connect the mass air flow meter connector.

-

-

CONNECT CABLE TO NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

PERFORM REGISTRATION

-

Perform registration of injector compensation codes Click here.

-

Perform registration of pilot quantity learning Click here.

-

-

BLEED AIR FROM FUEL SYSTEM

-

Using the hand pump mounted on the fuel filter cap, bleed the air from the fuel system. Continue pumping until the pump resistance increases.

Note

-

Hand pump pumping speed: Max. 2 strokes/ sec.

-

The hand pump must be pushed with a full stroke during pumping.

-

When the fuel pressure at the supply pump inlet port reaches a saturated pressure, the hand pump resistance increases.

-

If pumping is interrupted during the air bleeding process, fuel in the fuel line may return to the fuel tank. Continue pumping until the hand pump resistance increases.

-

If the hand pump resistance does not increase despite consecutively pumping 200 times or more, there may be a fuel leak between the fuel tank and fuel filter, the hand pump may be malfunctioning, or the vehicle may have run out of fuel.

-

If air bleeding using the hand pump is incomplete, the common rail pressure does not rise to the pressure range necessary for normal use, and the engine cannot be started.

-

-

Start the engine.

Note

-

Even if air bleeding using the hand pump has been completed, the starter may need to be cranked for 10 seconds or more to start the engine.

-

Do not crank the engine continuously for more than 20 seconds. The battery may be discharged.

-

Use a fully-charged battery.

-

When the engine can be started, proceed to the next step.

-

If the engine cannot be started, bleed the air again using the hand pump until the hand pump resistance increases (refer to the procedures above). Then start the engine.

-

-

Turn the ignition switch off.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON and turn the intelligent tester on.

-

Clear the DTCs Click here.

-

Start the engine.*1

-

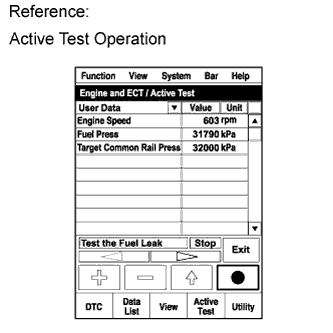

Enter the following menus: Powertrain / Engine and ECT / Active Test / Test the Fuel Leak.*2

-

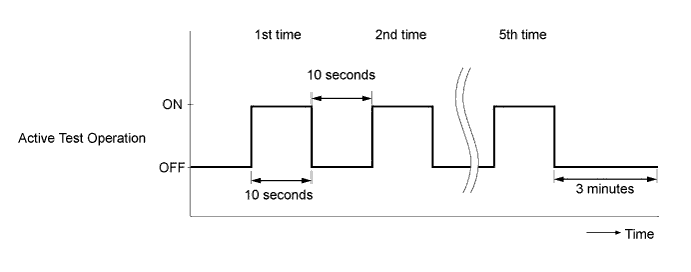

Perform the following test 5 times with on/off intervals of 10 seconds: Active Test / Test the Fuel Leak.*3

-

Allow the engine to idle for 3 minutes or more after performing the Active Test for the fifth time.

Tech Tips

When the Active Test "Test the Fuel Leak" is used to change the pump control mode, the actual fuel pressure inside the common rail drops below the target fuel pressure when the Active Test is off, but this is normal and does not indicate a pump malfunction.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read Current DTCs.

-

When no DTCs are output, the air bleeding is completed.

-

If any DTCs are output, proceed to the next step.

-

-

Clear the DTCs Click here.

-

Repeat steps *1 to *3.

-

Enter the following menus: Powertrain / Engine and ECT / DTC.

-

Read Current DTCs.

OK No DTCs are output.

-

-

INSPECT FOR FUEL LEAK

Tech Tips

Using the intelligent tester to perform Active Tests allow relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

-

Perform Active Test.

-

Connect the intelligent tester to the DLC3.

-

Turn the ignition switch to ON.

-

Start the engine.

-

Turn the intelligent tester on.

-

Enter the following menus: Powertrain / Engine / Active Test.

-

Perform the Active Test.

Tester Display Test Part Control Range Diagnostic Notes Test the Fuel Leak Pressurizes common rail internal fuel pressure, and checks for fuel leaks Stop/Start Performs inspection of the high pressure fuel system.

-

Engine Speed: 2050 rpm

-

Fuel Pressure: 172000 kPa

-

Target Common Rail Pressure: 176000 kPa

-

Target Pump SCV Current: 1.4 A

-

MAP: 176 kPa

-

MAF: 39 g/sec.

-

-

-

-

INSTALL NO. 1 ENGINE COVER

-

Attach the 4 clips to install the No. 1 engine cover.

-