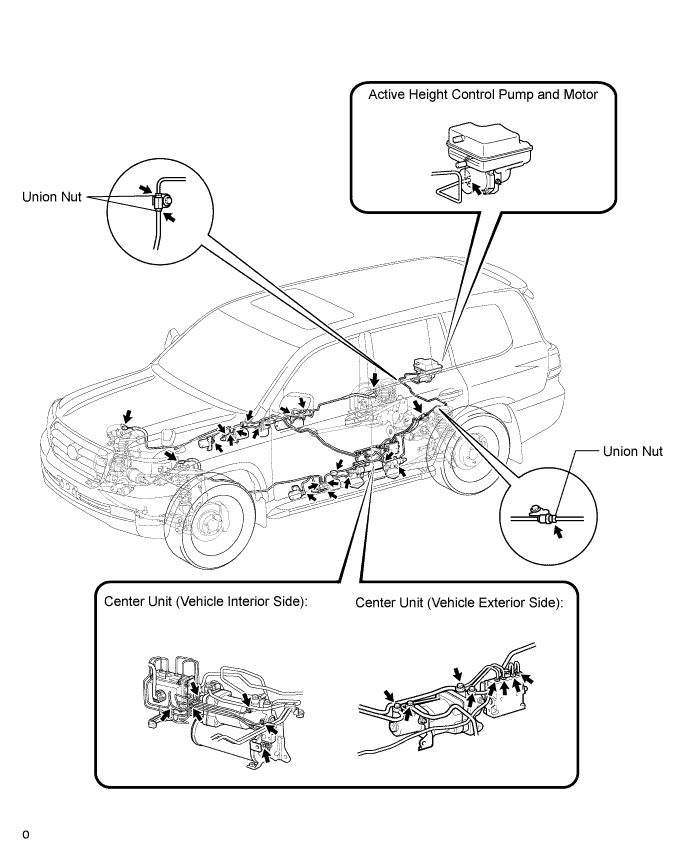

CONTROL VALVE ASSEMBLY INSTALLATION

-

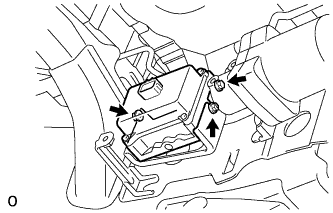

INSTALL NO. 1 HEIGHT CONTROL VALVE ASSEMBLY

-

Install the 3 bolt cushions and 3 bolt holders to the control valve.

-

Install the control valve with the 3 nuts.

- Torque:

- 5.5 N*m { 56 kgf*cm, 49 in.*lbf }

-

-

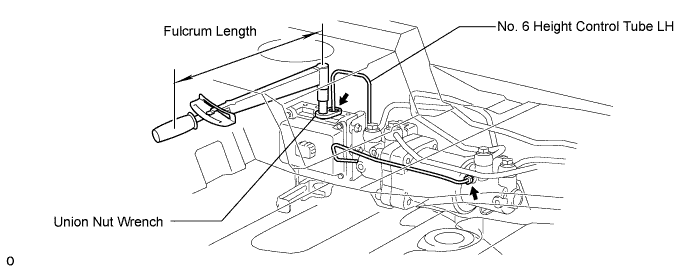

INSTALL NO. 6 HEIGHT CONTROL TUBE LH

-

Using a union nut wrench, install the No. 6 height control tube to the control valve and center cylinder.

- Torque:

- without union nut wrench

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

- with union nut wrench

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

Tech Tips

-

Use a torque wrench with a fulcrum length of 300 mm (11.8 in.).

-

The torque value for use with a union nut wrench is effective when the union nut wrench is parallel to the torque wrench.

-

-

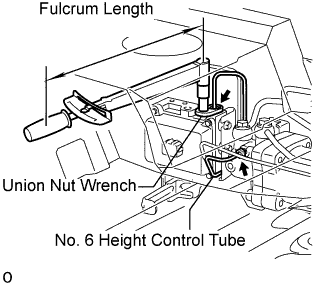

INSTALL NO. 6 HEIGHT CONTROL TUBE

-

Using a union nut wrench, install the No. 6 height control tube to the control valve and center cylinder.

- Torque:

- without union nut wrench

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

- with union nut wrench

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

Tech Tips

-

Use a torque wrench with a fulcrum length of 300 mm (11.8 in.).

-

The torque value for use with a union nut wrench is effective when the union nut wrench is parallel to the torque wrench.

-

-

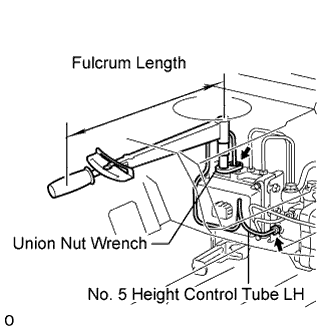

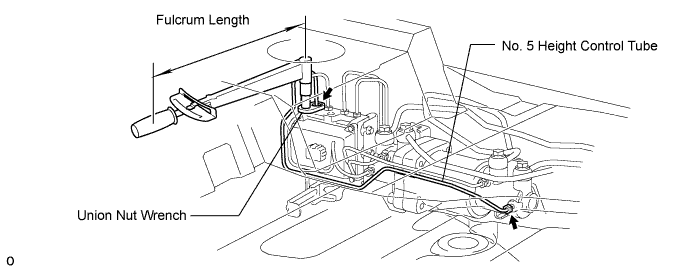

INSTALL NO. 5 HEIGHT CONTROL TUBE LH

-

Using a union nut wrench, install the No. 5 height control tube to the control valve and center cylinder.

- Torque:

- without union nut wrench

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

- with union nut wrench

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

Tech Tips

-

Use a torque wrench with a fulcrum length of 300 mm (11.8 in.).

-

The torque value for use with a union nut wrench is effective when the union nut wrench is parallel to the torque wrench.

-

-

INSTALL NO. 5 HEIGHT CONTROL TUBE

-

Using a union nut wrench, install the No. 5 height control tube to the control valve and center cylinder.

- Torque:

- without union nut wrench

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

- with union nut wrench

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

Tech Tips

-

Use a torque wrench with a fulcrum length of 300 mm (11.8 in.).

-

The torque value for use with a union nut wrench is effective when the union nut wrench is parallel to the torque wrench.

-

-

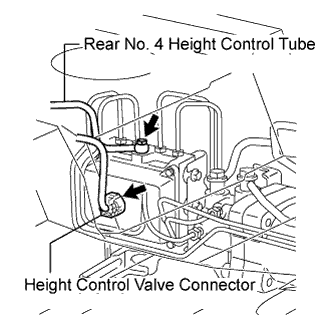

CONNECT REAR NO. 4 HEIGHT CONTROL TUBE

-

Install a new gasket to the control tube, and connect the control tube with the union bolt.

- Torque:

- 25 N*m { 255 kgf*cm, 18 ft.*lbf }

-

Connect the height control valve connector.

-

-

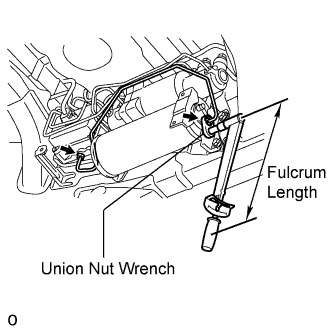

INSTALL NO. 7 HEIGHT CONTROL TUBE

-

Using a union nut wrench, install the No. 7 control tube to the control valve and accumulator.

- Torque:

- without union nut wrench

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

- with union nut wrench

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

Tech Tips

-

Use a torque wrench with a fulcrum length of 300 mm (11.8 in.).

-

The torque value for use with a union nut wrench is effective when the union nut wrench is parallel to the torque wrench.

-

-

INSTALL CLAMP

-

Install the clamp to the 3 height control tubes.

-

-

INSTALL CENTER EXHAUST PIPE ASSEMBLY

-

Install 2 new gaskets to the front exhaust pipe and front No. 2 exhaust pipe.

-

Install the center exhaust pipe to the 3 exhaust pipe supports, and then install the 4 bolts.

- Torque:

- 48 N*m { 489 kgf*cm, 35 ft.*lbf }

-

-

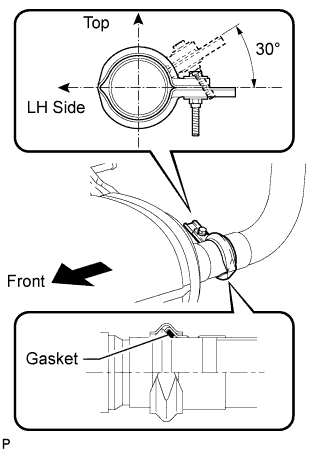

INSTALL TAILPIPE ASSEMBLY

-

Install the tailpipe to the 2 exhaust pipe supports.

-

Install a new gasket to the center exhaust pipe.

-

Connect the tailpipe to the center exhaust pipe.

-

Attach a new clamp to the tailpipe and center exhaust pipe. Then install the bolt to the clamp.

- Torque:

- 32 N*m { 326 kgf*cm, 24 ft.*lbf }

Tech Tips

Install the clamp within the angle range shown in the illustration.

-

-

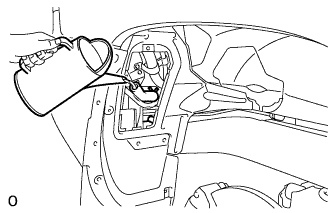

BLEED AIR FROM SUSPENSION FLUID

-

With the engine stopped, fill the reservoir tank with fluid.

Note

When the engine starts, the pump operates and fluid is supplied to each cylinder from the reservoir tank. Therefore, add the necessary amount of fluid so that the reservoir tank does not become empty.

Tech Tips

At this point, the vehicle height is low because the pressure of the cylinders is low.

-

With the vehicle on a level surface, start the engine and set the vehicle height to NORMAL with the suspension control switch.

-

When the vehicle height becomes NORMAL and the pump stops, stop the engine.

-

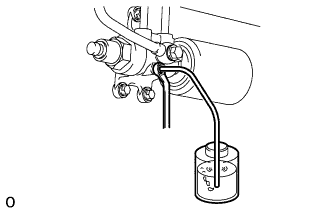

Connect a hose to the bleeder plug of the front left side or right side control valve, then loosen the bleeder plug.

CAUTION:

Be careful when loosening the control valve bleeder plug because the front vehicle height drops rapidly.

-

After the fluid containing air stops coming out, retighten the bleeder plug.

- Torque:

- 8.3 N*m { 85 kgf*cm, 73 in.*lbf }

Tech Tips

If the procedures are performed for the first time on the left side, perform the procedures on the right side for the second time.

-

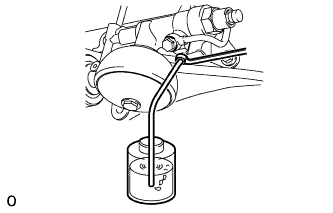

Connect a hose to the bleeder plug of the rear left side or right side control valve, then loosen the bleeder plug.

CAUTION:

Be careful when loosening the control valve bleeder plug because the rear vehicle height drops rapidly.

-

After the fluid containing air stops coming out, retighten the bleeder plug.

- Torque:

- 8.3 N*m { 85 kgf*cm, 73 in.*lbf }

Tech Tips

If the procedures are performed for the first time on the left side, perform the procedures on the right side for the second time.

-

Repeat the previous 4 procedures until the fluid containing air stops coming out.

-

-

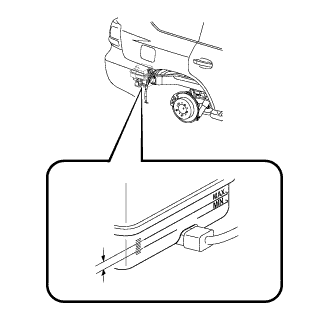

CHECK FLUID LEVEL IN RESERVOIR

-

With the vehicle empty, after setting the vehicle height to NORMAL from LO, check the indicator to make sure the vehicle height is NORMAL and check that the fluid level in the reservoir tank is within the specified range (MAX, MIN).

Tech Tips

After changing the vehicle height from LO to NORMAL, do not stop the engine for 25 seconds because the pressure control for the main accumulator is operating. After that, check the fluid level.

-

-

INSPECT FOR SUSPENSION FLUID LEAK

-

Check the torque value of the rear No. 5 height control tube union nuts.

- Torque:

- without union nut wrench

- 15 N*m { 155 kgf*cm, 11 ft.*lbf }

- with union nut wrench

- 14 N*m { 143 kgf*cm, 10 ft.*lbf }

Tech Tips

-

Use a torque wrench with a fulcrum length of 300 mm (11.8 in.).

-

The torque value for use with a union nut wrench is effective when the union nut wrench is parallel to the torque wrench.

-

Check for fluid leakage from the parts and connections.

Tech Tips

For union nuts and union bolts not shown in the illustration, refer to the installation procedures for each title.

-

-

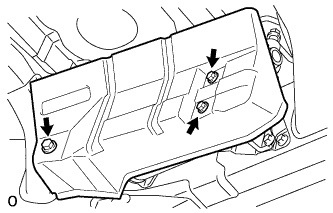

INSTALL HEIGHT CONTROL UNIT INSULATOR

-

Install the insulator to the height control unit with the 3 bolts.

- Torque:

- 31 N*m { 316 kgf*cm, 23 ft.*lbf }

-

-

INSPECT FOR EXHAUST GAS LEAK

-

If gas is leaking, tighten the areas necessary to stop the leak. Replace damaged parts as necessary.

-