ENGINE UNIT INSTALLATION

-

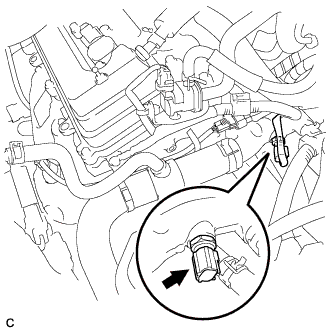

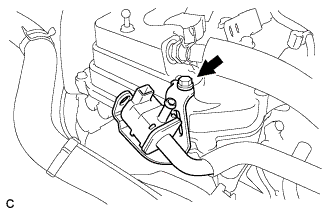

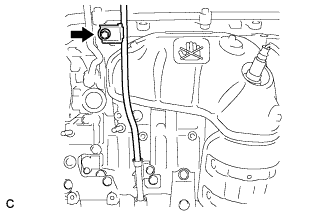

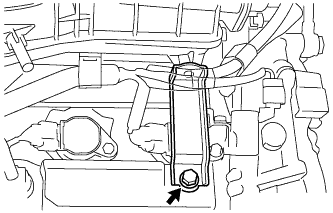

INSTALL ENGINE COOLANT TEMPERATURE SENSOR

-

Install a new gasket onto the engine coolant temperature sensor.

-

Install the engine coolant temperature sensor and gasket.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

-

Connect the engine coolant temperature sensor connector.

-

-

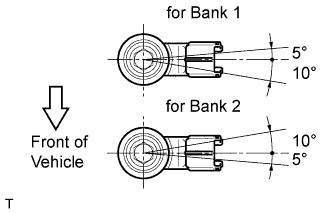

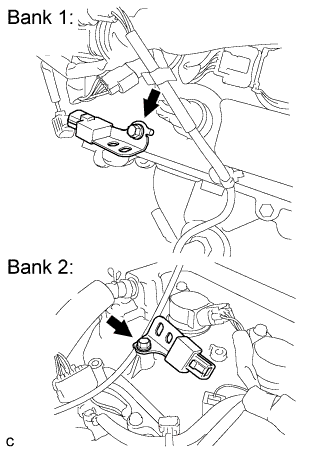

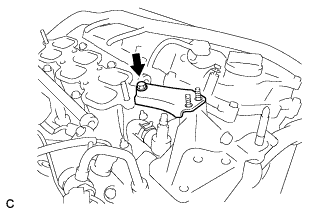

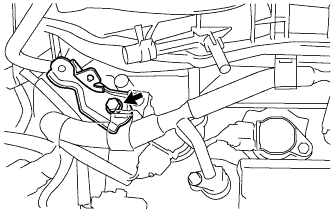

INSTALL KNOCK CONTROL SENSOR

-

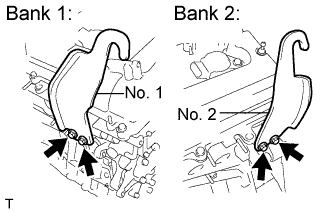

Install the 2 knock control sensors with the 2 bolts as shown in the illustration.

- Torque:

- 20 N*m { 204 kgf*cm, 15 ft.*lbf }

Note

Make sure that each knock control sensor is in the correct position.

-

Connect the 2 knock control sensor connectors.

-

-

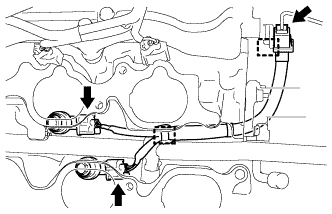

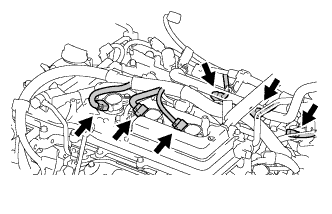

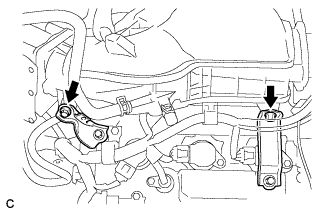

INSTALL KNOCK CONTROL SENSOR WIRE

-

Connect the 2 clamps, 2 knock control sensor connectors and knock control sensor wire connector.

-

-

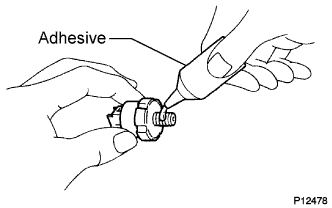

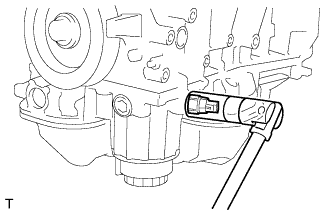

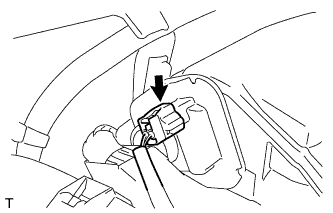

INSTALL ENGINE OIL PRESSURE SWITCH ASSEMBLY

-

Clean the threads of the oil pressure switch. Apply adhesive to 2 or 3 threads of the oil pressure switch assembly.

Adhesive Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent -

Using a 24 mm deep socket wrench, install the oil pressure switch.

- Torque:

- 15 N*m { 153 kgf*cm, 11 ft.*lbf }

Note

Do not start the engine within 1 hour after installation to prevent oil leaks.

-

-

INSTALL NO. 1 VACUUM SWITCHING VALVE ASSEMBLY

-

Install the bolt and No. 1 vacuum switching valve.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

-

INSTALL RADIO SETTING CONDENSER

-

Install the 2 bolts and 2 radio setting condensers.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

-

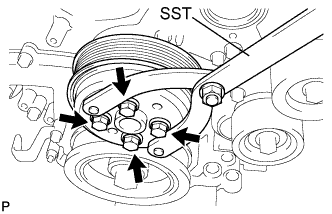

INSTALL WATER PUMP PULLEY

-

Temporarily install the water pump pulley with the 4 bolts.

-

Using SST, hold the water pump pulley.

- SST

- 09960-10010 ( 09962-01000, 09963-00700 )

-

Tighten the 4 bolts.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

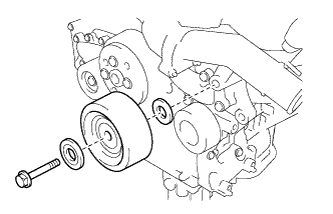

INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

-

Install the idler pulley cover plate, No. 2 idler pulley sub-assembly and No. 2 idler pulley cover plate with the bolt.

- Torque:

- 54 N*m { 550 kgf*cm, 40 ft.*lbf }

-

-

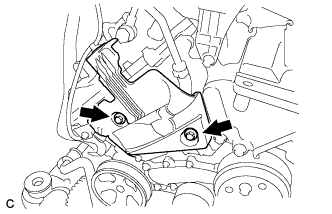

INSTALL NO. 2 TIMING GEAR COVER

-

Install the No. 2 timing gear cover with the 2 bolts.

- Torque:

- 6.0 N*m { 61 kgf*cm, 53 in.*lbf }

-

-

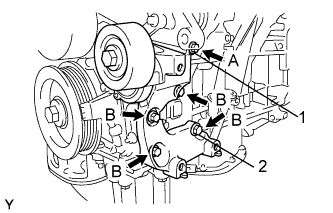

INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

-

Temporarily install the V-ribbed belt tensioner assembly with the 5 bolts.

Tech Tips

Each bolt length is as follows:

A: 70 mm (2.76 in.)

B: 33 mm (1.30 in.)

-

Install the V-ribbed belt tensioner assembly by tightening the bolt 1 and bolt 2 in the order shown in the illustration.

- Torque:

- 43 N*m { 438 kgf*cm, 32 ft.*lbf }

-

Tighten the other bolts.

- Torque:

- 43 N*m { 438 kgf*cm, 32 ft.*lbf }

-

-

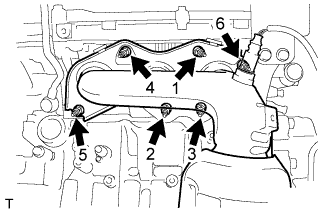

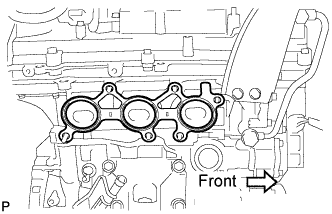

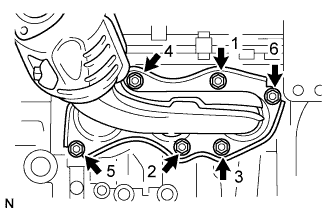

INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY LH

-

Install a new gasket as shown in the illustration.

-

Install the exhaust manifold sub-assembly LH with the 6 nuts in the order shown in the illustration.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

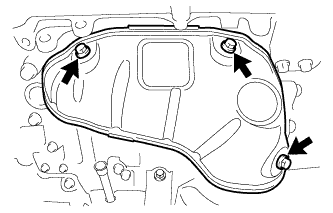

INSTALL NO. 2 EXHAUST MANIFOLD HEAT INSULATOR

-

Install the No. 2 exhaust manifold heat insulator with the 3 bolts.

- Torque:

- 8.5 N*m { 87 kgf*cm, 75 in.*lbf }

-

-

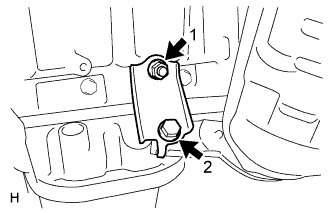

INSTALL NO. 2 MANIFOLD STAY

-

Install the No. 2 manifold stay by tightening the bolt and nut in the order shown in the illustration.

- Torque:

- 34 N*m { 347 kgf*cm, 25 ft.*lbf }

-

-

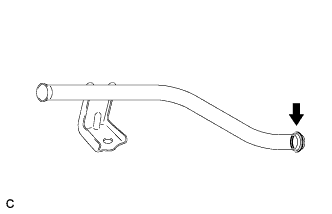

INSTALL NO. 2 ENGINE OIL LEVEL DIPSTICK GUIDE

-

Install a new O-ring to the No. 2 engine oil level dipstick guide.

-

Apply a light coat of engine oil to the O-ring.

-

Push in the No. 2 engine oil level dipstick guide end into the No. 1 engine oil level dipstick guide.

-

Install the No. 2 engine oil level dipstick guide with the bolt.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

Install the engine oil level dipstick.

-

-

INSTALL EXHAUST MANIFOLD SUB-ASSEMBLY RH

-

Install a new gasket as shown in the illustration.

-

Install the exhaust manifold sub-assembly RH with the 6 nuts in the order shown in the illustration.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

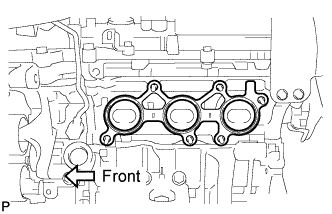

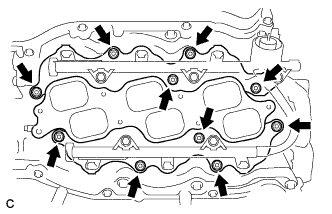

INSTALL INTAKE MANIFOLD

Note

DO NOT apply oil to the bolts listed below:

Tightening Part Intake Manifold and Cylinder Head Sub-assembly RH Intake Manifold and Cylinder Head Sub-assembly LH

-

Set a new gasket on each cylinder head.

Note

-

Align the port holes of the gasket and cylinder head.

-

Make sure that the gasket is installed in the correct direction.

-

-

Set the intake manifold on the cylinder heads.

-

Install and tighten the 6 bolts and 4 nuts uniformly in several steps.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

INSTALL NO. 2 ENGINE MOUNTING STAY RH

-

Install the No. 2 mounting stay RH with the bolt.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

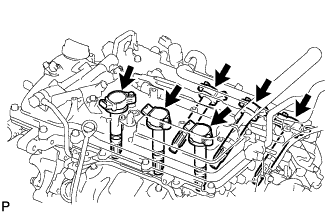

INSTALL IGNITION COIL ASSEMBLY

-

Install the 6 ignition coils with the 6 bolts.

- Torque:

- 10 N*m { 102 kgf*cm, 7 ft.*lbf }

-

Connect the 6 ignition coil connectors.

-

Connect the 3 wire harness clamps.

-

-

INSTALL THROTTLE BODY BRACKET

-

Install the throttle body bracket with the bolt.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

INSTALL NO. 1 SURGE TANK STAY

-

Install the No. 1 surge tank stay with the bolt.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

-

INSTALL INTAKE AIR SURGE TANK ASSEMBLY

NOTICE DO NOT apply oil to the bolts listed below: Tightening Part Surge Tank and Intake Manifold No. 1 Surge Tank Stay and Surge Tank Throttle Body Bracket and Surge Tank

-

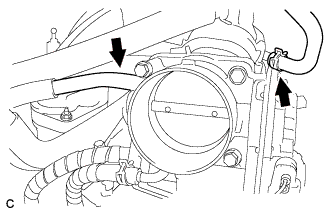

Install 3 new air surge tank to intake manifold gaskets to the intake air surge tank.

-

Using a 5 mm hexagon socket wrench, install the intake air surge tank assembly with the 4 bolts and 2 nuts.

- Torque:

- Bolt

- 18 N*m { 184 kgf*cm, 13 ft.*lbf }

- Nut

- 16 N*m { 163 kgf*cm, 12 ft.*lbf }

-

Install the throttle body bracket and No. 1 surge tank stay with the 2 bolts.

- Torque:

- 21 N*m { 214 kgf*cm, 15 ft.*lbf }

-

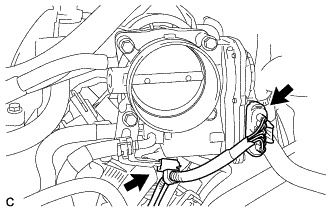

Connect the connector to the intake air control valve assembly.

-

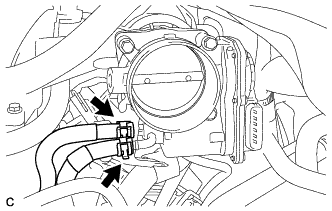

Connect the 2 water by-pass hoses to the throttle body assembly.

-

Connect the fuel vapor feed hose to the intake air surge tank assembly.

-

Connect the throttle body assembly connector and wire harness clamp to the throttle body assembly.

-

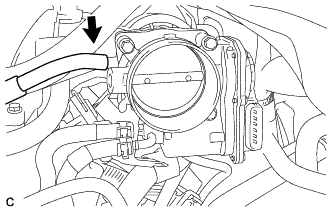

Connect the ventilation hose.

-

Connect the union to connector tube hose.

-

-

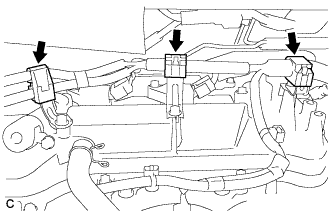

INSTALL ENGINE HANGERS

-

Install the 2 engine hangers with the 4 bolts as shown in the illustration.

Part No. No. 1 Engine hanger 12281-31120 No. 2 Engine hanger 12282-31100 Bolts 91671-10825 - Torque:

- 33 N*m { 337 kgf*cm, 24 ft.*lbf }

-

Attach the engine sling device and hang the engine with the chain block.

-

-

REMOVE ENGINE STAND