VEHICLE STABILITY CONTROL SYSTEM, Diagnostic DTC:C1426

DESCRIPTION

The skid control ECU (brake actuator assembly) receives stop light switch signals and uses them to determine whether or not the brakes are applied.

The skid control ECU (brake actuator assembly) has a detection circuit that it uses to detect a short in the stop light input line, or the ground line of the stop light circuit with the stop light switch on (brake pedal depressed).

If the skid control ECU (brake actuator assembly) detects a short in this circuit, it will store this DTC.

| DTC No. | DTC Detection Condition | Trouble Area |

|---|---|---|

| C1426 | When the brake pedal load sensing switch is on, the master cylinder pressure is 2 MPa (20.4 kgf/cm2, 290 psi) or more and the deceleration calculated from the vehicle speed is 0.2 G or more, the stop light switch is off for 2 seconds or more. |

|

WIRING DIAGRAM

Refer to DTCs C1425 and C1429 Click here and Click here.

INSPECTION PROCEDURE

Note

-

When replacing the skid control ECU (brake actuator assembly), perform zero point calibration Click here.

-

Inspect the fuses for circuits related to this system before performing the following inspection procedure.

PROCEDURE

-

CHECK BRAKE PEDAL HEIGHT AND STOP LIGHT SWITCH ASSEMBLY INSTALLATION

-

Check the brake pedal height and stop light switch assembly installation Click here for LHD or Click here for RHD).

OK The brake pedal height and stop light switch assembly installation are normal. Tech Tips

If the on/off status of the stop light switch assembly and the pressure increase information from the master cylinder pressure sensor do not match due to an improperly installed brake pedal or stop light switch assembly, this DTC may be stored. Therefore, be sure to check the installation condition of the pedal and switch before inspecting the input signals and other related parts.

Result Result Proceed to OK A NG (for LHD) B NG (for RHD) C

B

ADJUST BRAKE PEDAL HEIGHT OR STOP LIGHT SWITCH ASSEMBLY INSTALLATION Click here

C

ADJUST BRAKE PEDAL HEIGHT OR STOP LIGHT SWITCH ASSEMBLY INSTALLATION Click here

A

-

-

CHECK STOP LIGHT OPERATION

-

Check that the stop lights come on when the brake pedal is depressed, and go off when the brake pedal is released.

OK Condition Illumination Condition Brake pedal depressed. On Brake pedal released. Off

NG

INSPECT STOP LIGHT SWITCH ASSEMBLY Click here

OK

-

-

READ VALUE USING GTS (STOP LIGHT SWITCH ASSEMBLY AND BRAKE PEDAL LOAD SENSING SWITCH)

-

Connect the GTS to the DLC3.

-

Turn the engine switch on (IG).

-

Select the Data List using the GTS Click here.

ABS/VSC/TRC Tester Display Measurement Item/Range Normal Condition Diagnostic Note Stop Light SW Stop light switch assembly / ON or OFF ON: Brake pedal depressed

OFF: Brake pedal released

- Brake Pedal Load Sensing SW Brake pedal load sensing switch / ON or OFF ON: Brake pedal depressed beyond a specified point

OFF: Brake pedal not depressed beyond a specified point

- -

Check that the stop light switch display and brake pedal load sensing switch display observed on the GTS change according to brake pedal operation.

OK The GTS displays ON or OFF according to brake pedal operation. -

Slowly depress the brake pedal, and check when the stop light switch and brake pedal load sensing switch turn on.

OK First the stop light switch should turn on, and then the brake pedal load sensing switch should turn on. Result Result Proceed to OK A NG (The stop light switch does not turn on.) B NG (Turning on of the brake pedal load sensing switch is not confirmed.) C NG (The brake pedal load sensing switch turns on first.) (for LHD) D NG (The brake pedal load sensing switch turns on first.) (for RHD) E

B

CHECK HARNESS AND CONNECTOR (STP TERMINAL) Click here

C

INSPECT BRAKE PEDAL SUPPORT ASSEMBLY Click here

D

REPLACE BRAKE PEDAL SUPPORT ASSEMBLY Click here

E

REPLACE BRAKE PEDAL SUPPORT ASSEMBLY Click here

A

-

-

RECONFIRM DTC

-

Turn the engine switch off.

-

Clear the DTCs Click here.

-

Turn the engine switch off.

-

Start the engine.

-

Depress the brake pedal several times to test the stop light circuit.

-

Check if the same DTC is output Click here.

Result Result Proceed to DTC C1426 is not output. A DTC C1426 is output. B Tech Tips

If troubleshooting has been carried out according to Problem Symptoms Table, refer back to the table and proceed to the next step before replacing parts Click here.

B

REPLACE BRAKE ACTUATOR ASSEMBLY Click here

A

USE SIMULATION METHOD TO CHECK Click here

-

-

INSPECT STOP LIGHT SWITCH ASSEMBLY

-

Inspect the stop light switch assembly Click here.

OK The stop light switch assembly is normal.

NG

REPLACE STOP LIGHT SWITCH ASSEMBLY Click here

OK

-

-

CHECK HARNESS AND CONNECTOR (STPS TERMINAL)

-

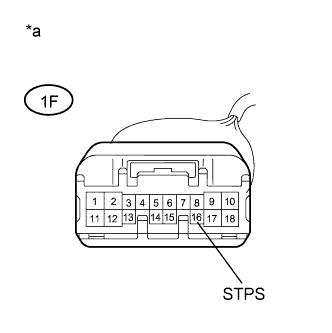

Text in Illustration *a Front view of wire harness connector

(to No. 1 Integration Relay (Engine Room Junction Block Assembly))

Disconnect the 1F No. 1 integration relay (engine room junction block assembly) connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition 1F-16 (STPS) - Body ground Stop light switch assembly ON (Brake pedal depressed) 11 to 14 V 1F-16 (STPS) - Body ground Stop light switch assembly OFF (Brake pedal released) Below 1.5 V

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (STPS CIRCUIT)

OK

-

-

CHECK HARNESS AND CONNECTOR (STP TERMINAL)

-

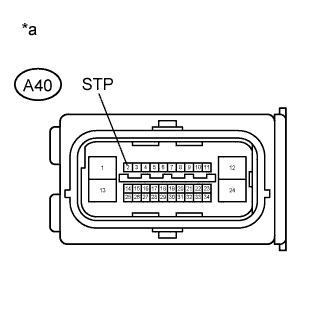

Text in Illustration *a Front view of wire harness connector

(to Skid Control ECU (Brake Actuator Assembly))

Make sure that there is no looseness at the locking part and the connecting part of the connector.

-

Disconnect the A40 skid control ECU (brake actuator assembly) connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition A40-2 (STP) - Body ground Stop light switch ON (Brake pedal depressed) 11 to 14 V A40-2 (STP) - Body ground Stop light switch OFF (Brake pedal released) Below 1.5 V

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (STP CIRCUIT)

OK

-

-

RECONFIRM DTC

-

Reconnect the 1F No. 1 integration relay (engine room junction block assembly) connector.

-

Reconnect the A40 skid control ECU (brake actuator assembly) connector.

-

Clear the DTCs Click here.

-

Turn the engine switch off.

-

Start the engine.

-

Depress the brake pedal several times to test the stop light circuit.

-

Check if the same DTC is output Click here.

Result Result Proceed to DTC C1426 is not output. A DTC C1426 is output. B Tech Tips

-

If the lighting system is normal but the DTC is still output, replace the skid control ECU (brake actuator assembly) Click here.

-

If troubleshooting has been carried out according to Problem Symptoms Table, refer back to the table and proceed to the next step before replacing parts Click here.

-

B

INSPECT LIGHTING SYSTEM (STOP LIGHT CIRCUIT) Click here

A

USE SIMULATION METHOD TO CHECK Click here

-

-

CHECK HARNESS AND CONNECTOR (STP TERMINAL)

-

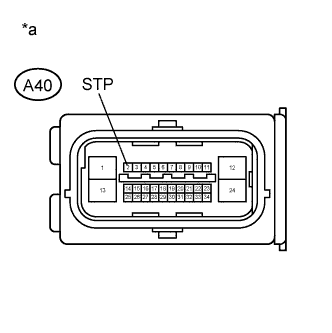

Text in Illustration *a Front view of wire harness connector

(to Skid Control ECU (Brake Actuator Assembly))

Turn the engine switch off.

-

Make sure that there is no looseness at the locking part and the connecting part of the connector.

-

Disconnect the A40 skid control ECU (brake actuator assembly) connector.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition A40-2 (STP) - Body ground Stop light switch ON (Brake pedal depressed) 11 to 14 V A40-2 (STP) - Body ground Stop light switch OFF (Brake pedal released) Below 1.5 V

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (STP CIRCUIT)

OK

-

-

CHECK HARNESS AND CONNECTOR (GND1 TERMINAL)

-

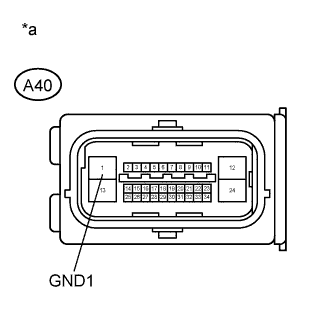

Text in Illustration *a Front view of wire harness connector

(to Skid Control ECU (Brake Actuator Assembly))

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A40-1 (GND1) - Body ground Always Below 1 Ω Tech Tips

If troubleshooting has been carried out according to Problem Symptoms Table, refer back to the table and proceed to the next step before replacing parts Click here.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR (GND1 CIRCUIT)

OK

REPLACE BRAKE ACTUATOR ASSEMBLY Click here

-

-

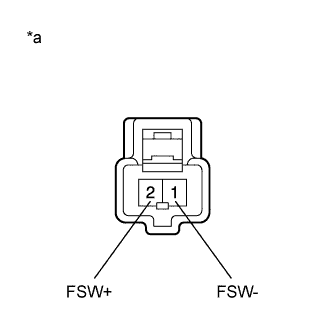

INSPECT BRAKE PEDAL SUPPORT ASSEMBLY

-

Text in Illustration *a Component without harness connected

(Brake Pedal Load Sensing Switch (Brake Pedal Support Assembly))

Turn the engine switch off.

-

Make sure that there is no looseness at the locking part and the connecting part of the connector.

-

Disconnect the A32 brake pedal load sensing switch (brake pedal support assembly) connector.

Note

-

Do not remove the brake pedal load sensing switch from the brake pedal support assembly.

-

When there is a malfunction in the brake pedal load sensing switch, replace the brake pedal support assembly.

-

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition 2 (FSW+) - 1 (FSW-) Switch OFF

(Brake pedal depressed)

950 to 1050 Ω 2 (FSW+) - 1 (FSW-) Switch ON

(Brake pedal released)

203 to 223 Ω Result Result Proceed to OK A NG (for LHD) B NG (for RHD) C

B

REPLACE BRAKE PEDAL SUPPORT ASSEMBLY Click here

C

REPLACE BRAKE PEDAL SUPPORT ASSEMBLY Click here

A

-

-

CHECK HARNESS AND CONNECTOR (BRAKE ACTUATOR ASSEMBLY - BRAKE PEDAL SUPPORT ASSEMBLY)

-

Make sure that there is no looseness at the locking part and the connecting part of the connector.

-

Disconnect the A40 skid control ECU (brake actuator assembly) connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition A40-27 (FSW+) - A32-2 (FSW+) Always Below 1 Ω A40-27 (FSW+) - Body ground Always 10 kΩ or higher A32-1 (FSW-) - Body ground Always Below 1 Ω Tech Tips

If troubleshooting has been carried out according to Problem Symptoms Table, refer back to the table and proceed to the next step before replacing parts Click here.

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR

OK

REPLACE BRAKE ACTUATOR ASSEMBLY Click here

-