ENGINE ASSEMBLY REMOVAL

-

PRECAUTION

CAUTION:

The engine assembly with transaxle is very heavy. Be sure to follow the procedure described in the repair manual, or the engine lifter may suddenly drop.

Note

After turning the engine switch off, waiting time may be required before disconnecting the cable from the negative (-) battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) battery terminal notices before proceeding with work Click here.

-

RECOVER REFRIGERANT FROM REFRIGERATION SYSTEM

-

Start the engine.

-

Operate the cooler compressor under the conditions shown below:

Item Condition Indicator Operating Time 3 minutes or more - Temperature setting Max cool - Blower speed High

Engine Idling - A/C switch On

This causes most of the compressor oil from the various components of the A/C system to collect in the A/C compressor.

Tech Tips

It is not necessary to operate the cooler compressor if the A/C does not operate because of compressor lock, etc.

-

Stop the engine.

-

Recover the refrigerant from the A/C system using a refrigerant recovery unit.

Tech Tips

Use the refrigerant recovery unit in accordance with the manufacturer's instruction manual.

-

-

DISCHARGE FUEL SYSTEM PRESSURE

-

PLACE FRONT WHEELS FACING STRAIGHT AHEAD

-

SECURE STEERING WHEEL

-

REMOVE FRONT WHEELS

-

DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL

Note

When disconnecting the cable, some systems need to be initialized after the cable is reconnected Click here.

-

REMOVE FRONT WHEEL OPENING EXTENSION PAD RH

-

Remove the 3 screws and front wheel opening extension pad RH.

-

-

REMOVE ENGINE UNDER COVER RH

-

Remove the 2 screws, 3 clips and engine under cover RH.

-

-

REMOVE FRONT WHEEL OPENING EXTENSION PAD LH

-

Remove the 3 screws and front wheel opening extension pad LH.

-

-

REMOVE ENGINE UNDER COVER LH

-

Remove the 2 screws, 2 clips and engine under cover LH.

-

-

REMOVE FRONT FENDER APRON SEAL LH

-

Remove the 2 bolts, clip and front fender apron seal LH.

-

-

REMOVE FRONT FENDER APRON SEAL RH

-

Remove the 2 bolts, clip and front fender apron seal RH.

-

-

DRAIN ENGINE OIL

-

Remove the oil filler cap.

-

Remove the oil pan drain plug and gasket, and drain the engine oil into a container.

-

Clean the oil pan drain plug.

-

Install the oil pan drain plug with a new gasket.

- Torque:

- 40 N*m { 408 kgf*cm, 30 ft.*lbf }

-

-

DRAIN ENGINE COOLANT

Note

Do not remove the radiator cap sub-assembly or radiator drain cock plug while the engine and radiator assembly are still hot. Pressurized, hot engine coolant and steam may be released and cause serious burns.

-

Loosen the radiator drain cock plug.

-

Remove the radiator cap sub-assembly.

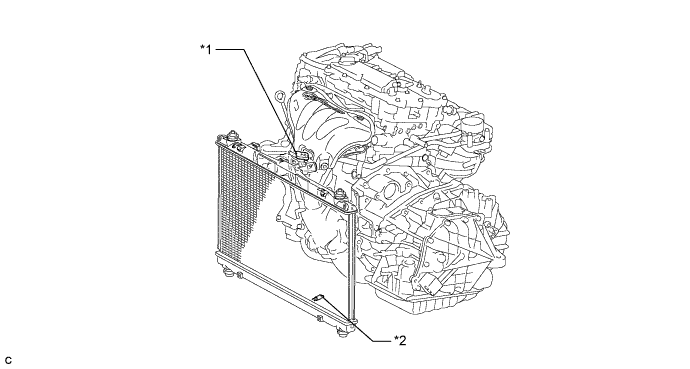

Text in Illustration *1 Radiator Cap Sub-assembly *2 Radiator Drain Cock Plug Tech Tips

Collect the engine coolant in a container and dispose of it according to the regulations in your area.

-

-

DRAIN AUTOMATIC TRANSAXLE FLUID

-

Remove the front wheel opening extension pad LH, engine under cover LH and front fender apron seal LH.

-

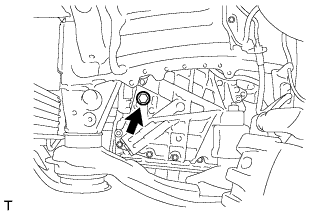

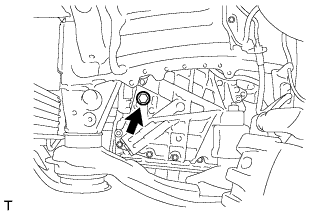

Remove the refill plug and gasket from the automatic transaxle assembly.

-

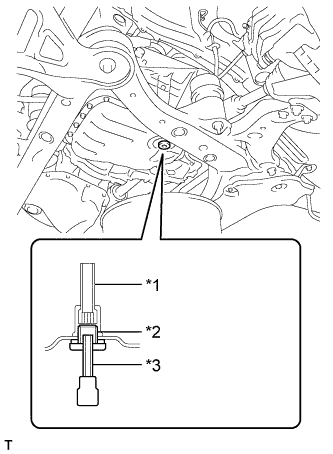

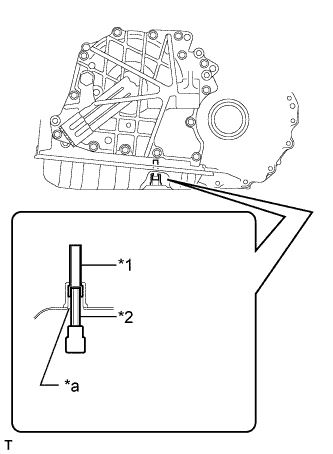

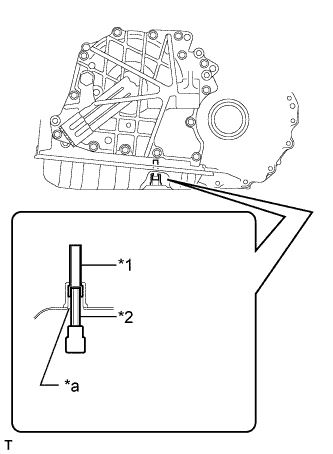

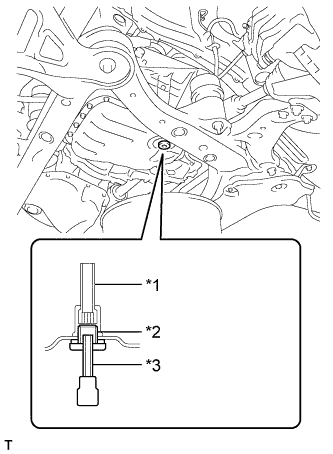

Text in Illustration *1 No. 1 Transmission Oil Filler Tube *2 Overflow Plug *3 Hexagon Socket Wrench Using a 6 mm hexagon socket wrench, remove the overflow plug and gasket from the automatic transaxle assembly.

-

Text in Illustration *1 No. 1 Transmission Oil Filler Tube *2 Hexagon Socket Wrench *a Overflow Plug Hole Using a 6 mm hexagon socket wrench, remove the No. 1 transmission oil filler tube from the automatic transaxle assembly.

-

Drain automatic transaxle fluid from the automatic transaxle assembly.

-

Text in Illustration *1 No. 1 Transmission Oil Filler Tube *2 Hexagon Socket Wrench *a Overflow Plug Hole Using a 6 mm hexagon socket wrench, install the No. 1 transmission oil filler tube to the automatic transaxle assembly.

- Torque:

- 0.8 N*m { 8 kgf*cm, 7 in.*lbf }

-

Text in Illustration *1 No. 1 Transmission Oil Filler Tube *2 Overflow Plug *3 Hexagon Socket Wrench Using a 6 mm hexagon socket wrench, install a new gasket and the overflow plug to the automatic transaxle assembly.

- Torque:

- 40 N*m { 408 kgf*cm, 29 ft.*lbf }

-

Install a new gasket and the refill plug to the automatic transaxle assembly.

- Torque:

- 49 N*m { 500 kgf*cm, 36 ft.*lbf }

-

-

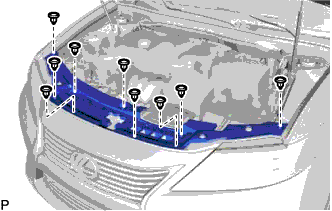

REMOVE COOL AIR INTAKE DUCT SEAL

-

Remove the 9 clips and cool air intake duct seal.

-

-

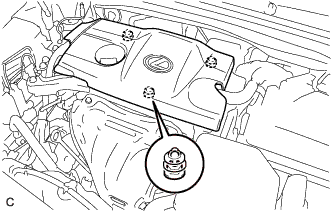

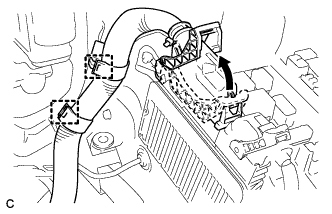

REMOVE NO. 1 ENGINE COVER SUB-ASSEMBLY

-

Lift the rear of the No. 1 engine cover sub-assembly to detach it from the 2 pins.

-

Lift the front of the No. 1 engine cover sub-assembly to detach the it from the pin and remove it.

Note

Attempting to disengage both front and rear pins at the same time may cause the No. 1 engine cover sub-assembly to break.

-

-

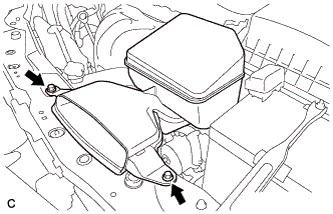

REMOVE INLET AIR CLEANER ASSEMBLY

-

Remove the 2 bolts and inlet air cleaner assembly.

-

-

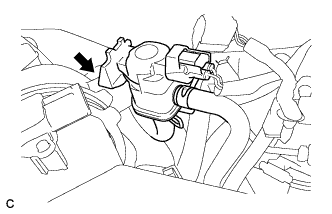

REMOVE AIR CLEANER CAP SUB-ASSEMBLY

-

Disconnect the vacuum switching valve assembly from the air cleaner cap sub-assembly.

-

Disconnect the mass air flow meter connector and separate the 2 wire harness clamps from the air cleaner cap sub-assembly.

-

Separate the fuel vapor feed hose from the air cleaner cap sub-assembly.

-

Disconnect the ventilation hose from the cylinder head cover.

-

Loosen the hose clamp and disconnect the air cleaner cap sub-assembly from the throttle with motor body assembly.

-

Release the 2 clamps and remove the air cleaner cap sub-assembly.

-

-

REMOVE AIR CLEANER FILTER ELEMENT SUB-ASSEMBLY

-

Remove the air cleaner filter element sub-assembly.

-

-

REMOVE AIR CLEANER CASE SUB-ASSEMBLY

-

Disconnect the wire harness clamp.

-

Remove the 2 bolts and air cleaner case sub-assembly.

-

-

REMOVE BATTERY

-

Loosen the nut, and disconnect the cable from the positive (+) battery terminal.

-

Loosen the nut, and remove the bolt and battery clamp.

-

Remove the battery and battery tray.

-

-

REMOVE RADIATOR RESERVE TANK ASSEMBLY

-

Disconnect the radiator reserve tank hose.

-

Remove the 2 bolts and radiator reserve tank assembly.

-

-

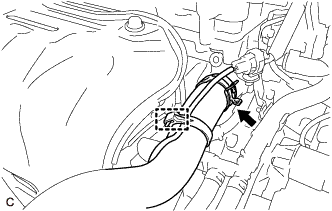

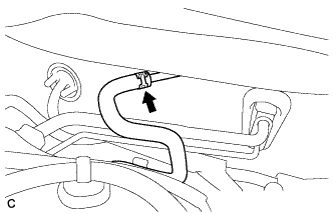

DISCONNECT NO. 1 RADIATOR HOSE

-

Remove the hose clamp to separate the air fuel ratio sensor wire from the No. 1 radiator hose.

-

Slide the clip and disconnect the No. 1 radiator hose.

-

-

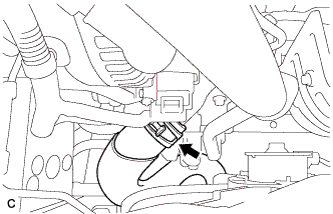

DISCONNECT NO. 2 RADIATOR HOSE

-

Slide the clip and disconnect the No. 2 radiator hose.

-

-

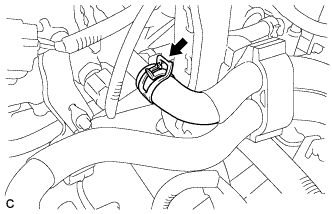

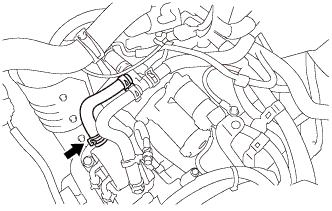

DISCONNECT INLET HEATER WATER HOSE

-

Slide the clip and disconnect the inlet heater water hose.

-

-

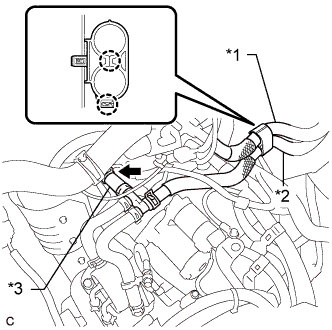

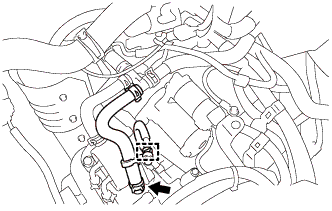

DISCONNECT OUTLET HEATER WATER HOSE B

-

Text in Illustration *1 Inlet Heater Water Hose *2 Outlet Heater Water Hose A *3 Outlet Heater Water Hose B Disengage the 2 claws and disconnect the inlet heater water hose and outlet heater water hose A.

-

Slide the clip and disconnect the outlet heater water hose B.

-

-

DISCONNECT NO. 4 WATER BY-PASS HOSE

-

Slide the clip and disconnect the No. 4 water by-pass hose.

-

-

DISCONNECT NO. 3 WATER BY-PASS HOSE

-

Disconnect the breather plug from the No. 3 water by-pass hose.

-

Slide the clip and disconnect the No. 3 water by-pass hose.

-

-

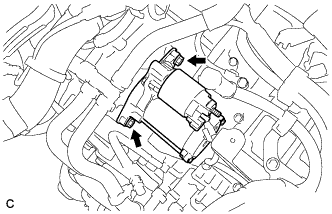

REMOVE STARTER ASSEMBLY

-

Disconnect the connector.

-

Open the cap, remove the nut and disconnect the wire harness.

-

Remove the 2 bolts and starter assembly.

-

-

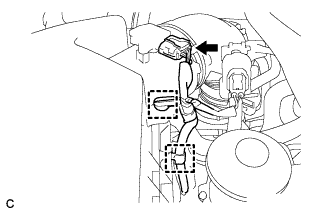

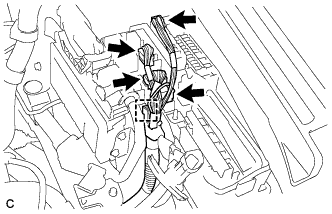

DISCONNECT ENGINE WIRE

-

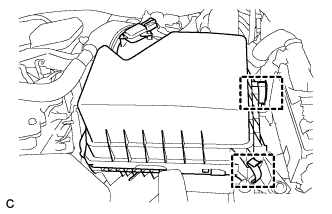

Remove the No. 1 relay block cover.

-

Remove the 2 nuts and disconnect the wire clamp.

-

Using a screwdriver, unlock the clamp and separate the engine wire from the engine room relay block.

-

Disconnect the 4 connectors.

-

Using a screwdriver, unlock the clamp and separate the engine wire from the engine room relay block.

-

Pull up the lever to disconnect the ECM connector.

-

Disconnect the 2 wire clamps.

-

-

REMOVE NO. 1 AIR CLEANER BRACKET

-

Disconnect the 2 wire clamps.

-

Remove the bolt and No. 1 air cleaner bracket.

-

-

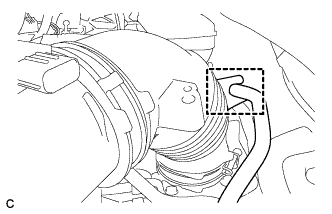

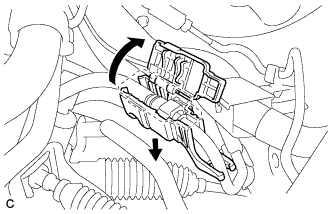

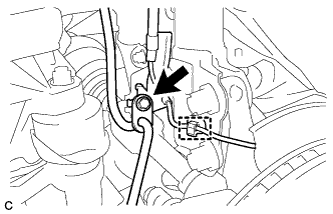

DISCONNECT TRANSMISSION CONTROL CABLE ASSEMBLY

-

Remove the nut and disconnect the transmission control cable assembly from the control shaft lever.

-

Remove the clip and disconnect the transmission control cable assembly from the No. 1 control cable bracket.

-

-

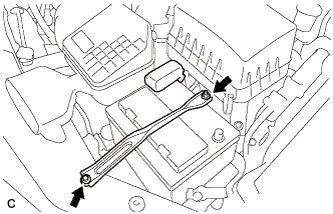

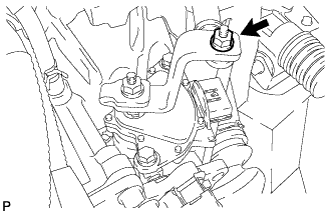

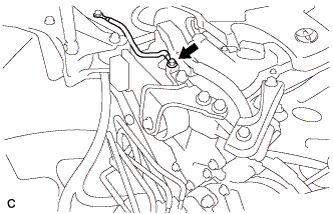

REMOVE NO. 2 ENGINE MOUNTING STAY RH

-

Remove the 2 bolts and No. 2 engine mounting stay RH.

-

-

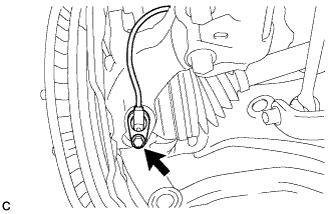

DISCONNECT EARTH WIRE

-

Remove the bolt to disconnect the earth wire from the engine moving control rod bracket.

-

-

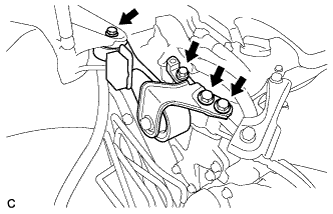

REMOVE ENGINE MOVING CONTROL ROD BRACKET

-

Remove the 4 bolts and engine moving control rod bracket.

-

-

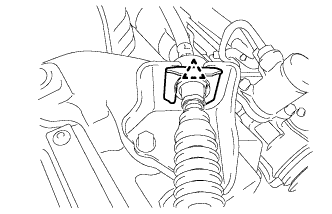

REMOVE ENGINE MOVING CONTROL ROD

-

Remove the bolt, engine moving control rod and No. 3 engine mounting stay RH from the engine moving control rod bracket.

Tech Tips

Perform this procedure only when replacement of the engine moving control rod is necessary.

-

-

DISCONNECT UNION TO VACUUM TUBE HOSE (for LHD)

-

Slide the clip and disconnect the union to vacuum tube hose.

-

-

DISCONNECT UNION TO CHECK VALVE HOSE (for RHD)

-

Slide the clip and disconnect the union to check valve hose.

-

-

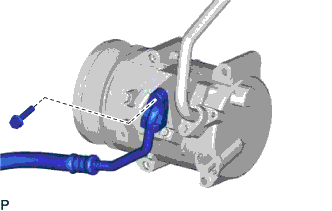

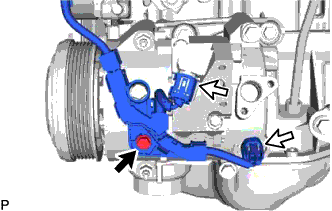

DISCONNECT NO. 1 COOLER REFRIGERANT DISCHARGE HOSE

-

Remove the bolt and disconnect the No. 1 cooler refrigerant discharge hose from the compressor assembly with pulley.

-

Remove the O-ring from the No. 1 cooler refrigerant discharge hose.

Note

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

-

-

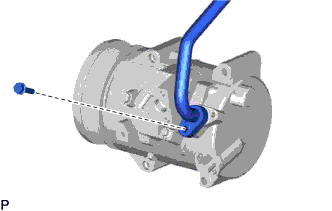

DISCONNECT NO. 1 COOLER REFRIGERANT SUCTION HOSE

-

Remove the bolt and disconnect the No. 1 cooler refrigerant suction hose from the compressor assembly with pulley.

-

Remove the O-ring from the No. 1 cooler refrigerant suction hose.

Note

Seal the openings of the disconnected parts using vinyl tape to prevent entry of moisture and foreign matter.

-

-

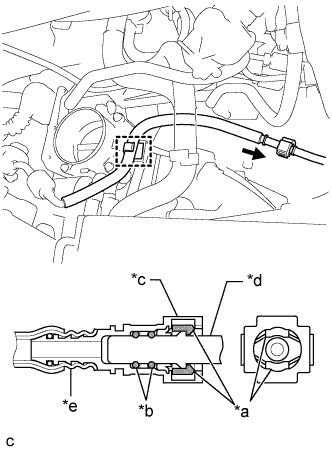

DISCONNECT FUEL TUBE SUB-ASSEMBLY

Note

Remove any dirt or foreign matter on the fuel tube connector and fuel pipe before performing this work.

-

Disengage the claw and remove the No. 1 fuel pipe clamp.

-

Disconnect the fuel tube sub-assembly from the fuel pipe.

-

Text in Illustration *a Retainer *b O-ring *c Fuel Tube Connector *d Fuel Pipe *e Nylon Tube

Pinch

Pull Pinch the retainer of the fuel tube connector, and then pull the fuel tube connector off of the fuel pipe.

Note

Be sure to disconnect the fuel tube connector by hand.

-

If the fuel tube connector and fuel pipe are stuck, push and pull the fuel tube connector to release it. Pull the fuel tube connector off of the fuel pipe carefully.

Note

-

Be sure to disconnect the fuel tube connector by hand.

-

Do not allow any scratches or foreign matter to get on the parts when disconnecting them as the fuel tube connector has O-rings that seal the fuel pipe.

-

Do not forcibly bend, twist or turn the nylon tube.

-

-

Check if there is any foreign matter on the sealing surfaces of the disconnected fuel lines. Clean them if necessary.

-

Cover the disconnected fuel pipe and fuel tube connector with plastic bags to prevent damage and contamination.

-

-

Disengage the clamp to disconnect the fuel tube sub-assembly from the fuel hose clamp.

-

-

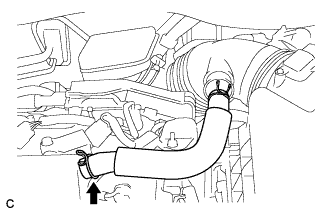

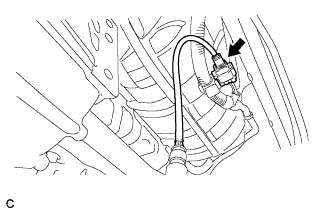

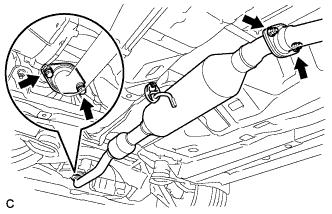

REMOVE FRONT EXHAUST PIPE ASSEMBLY

-

Disconnect the heated oxygen sensor connector.

-

Remove the 2 bolts, 2 compression springs and 2 nuts.

-

Remove the front exhaust pipe assembly from the exhaust pipe support.

-

Remove the 2 gaskets from the exhaust manifold converter sub-assembly and front exhaust pipe assembly.

-

-

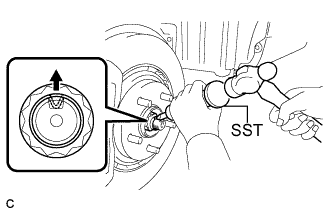

REMOVE FRONT AXLE SHAFT NUT LH

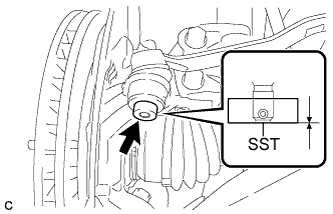

-

Using SST and a hammer, release the staked part of the front axle shaft nut.

- SST

- 09930-00010

Note

Loosen the staked part of the nut completely, otherwise the threads of the drive shaft may be damaged.

-

While applying the brakes, remove the front axle shaft nut.

-

-

REMOVE FRONT AXLE SHAFT NUT RH

Tech Tips

Use the same procedure described for the LH side.

-

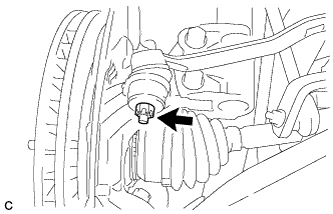

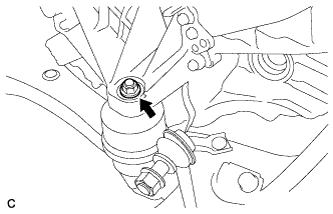

SEPARATE FRONT STABILIZER LINK ASSEMBLY LH

-

Remove the nut and separate the front stabilizer link assembly from the front shock absorber assembly.

If the ball joint turns together with the nut, use a hexagon wrench to hold the stud bolt.

-

-

SEPARATE FRONT STABILIZER LINK ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

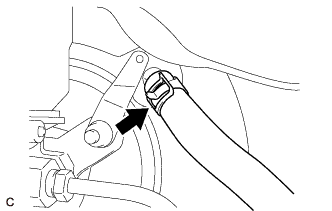

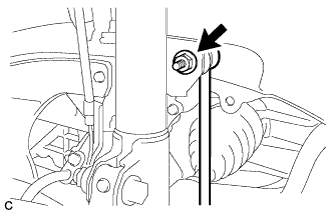

SEPARATE FRONT SPEED SENSOR LH

-

Remove the bolt, disengage the clamp and separate the front speed sensor and front flexible hose from the front shock absorber.

Note

Be sure to separate the front speed sensor from the front shock absorber completely.

-

Remove the bolt and front speed sensor from the steering knuckle.

Note

-

Prevent foreign matter from contacting the sensor tip.

-

Be careful not to damage the front speed sensor.

-

Clean the speed sensor installation hole and the contact surfaces every time the speed sensor is removed.

-

-

-

SEPARATE FRONT SPEED SENSOR RH

Tech Tips

Use the same procedure described for the LH side.

-

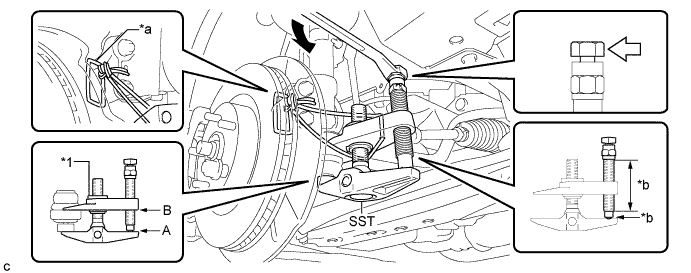

SEPARATE TIE ROD ASSEMBLY LH

-

Remove the cotter pin and nut.

-

Install SST to the tie rod assembly LH.

- SST

- 09960-20010 ( 09961-02060 )

Note

Make sure that the lower ends of the tie rod assembly LH and SST are aligned.

-

Secure SST using a string.

Note

Be sure to tighten the string firmly to secure SST to the steering knuckle to prevent SST from falling off.

-

Using SST, separate the tie rod assembly LH from the steering knuckle.

Text in Illustration *1 Center Nut - - *a String *b Molybdenum Grease Application Area

Place the wrench here. - - - SST

- 09960-20010 ( 09961-02010 )

CAUTION:

Apply molybdenum grease to the bolt threads and the tip of SST.

Note

-

Make sure to tie the string of SST to the steering knuckle to prevent SST from dropping.

-

Install SST with the center nut so that A and B shown in the illustration are parallel. Otherwise, the dust cover may be damaged.

-

Be sure to place the wrench on the part indicated in the illustration.

-

Do not damage the front disc brake dust cover.

-

Do not damage the ball joint dust cover.

-

Do not damage the steering knuckle.

-

-

SEPARATE TIE ROD ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

SEPARATE FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY LH

-

Remove the bolt and 2 nuts, and separate the front lower No. 1 suspension arm sub-assembly from the front lower ball joint assembly.

-

-

SEPARATE FRONT LOWER NO. 1 SUSPENSION ARM SUB-ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

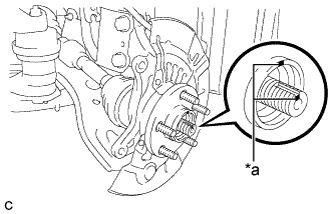

SEPARATE FRONT DRIVE SHAFT ASSEMBLY LH

-

Text in Illustration *a Matchmark Put matchmarks on the front drive shaft assembly and the front axle hub sub-assembly.

-

Using a plastic hammer, separate the front drive shaft assembly from the front axle assembly.

If it is difficult to separate, tap the end of the front drive shaft assembly using a brass bar and a hammer.

-

-

SEPARATE FRONT DRIVE SHAFT ASSEMBLY RH

Tech Tips

Use the same procedure described for the LH side.

-

REMOVE FRONT DRIVE SHAFT ASSEMBLY LH

-

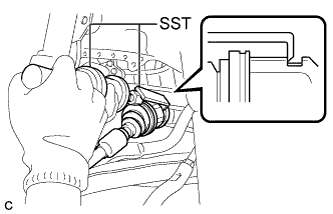

Using SST, remove the front drive shaft assembly LH.

- SST

- 09520-01010

- 09520-24010 ( 09520-32040 )

Note

-

Do not damage the transaxle case oil seal.

-

Do not damage the front axle inboard joint boot.

-

Do not drop the front drive shaft assembly LH.

-

-

REMOVE FRONT DRIVE SHAFT HOLE SNAP RING LH

-

Using a screwdriver, remove the front drive shaft hole snap ring LH.

-

-

REMOVE FRONT DRIVE SHAFT ASSEMBLY RH

-

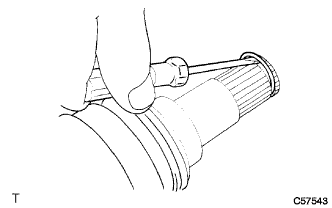

Separate the bearing bracket hole snap ring from the drive shaft bearing bracket.

-

Remove the bolt and front drive shaft assembly RH from the drive shaft bearing bracket.

Note

-

Do not damage the front transaxle case oil seal.

-

Do not damage the front axle inboard joint boot.

-

Do not drop the front drive shaft assembly RH.

-

-

Remove the bearing bracket hole snap ring from the front drive shaft assembly RH.

-

-

SEPARATE STEERING INTERMEDIATE SHAFT ASSEMBLY

-

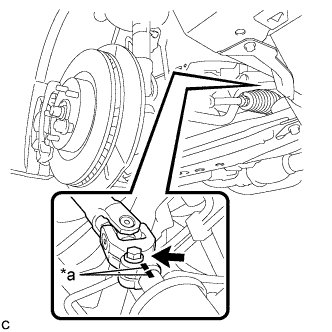

Text in Illustration *a Matchmark Put matchmarks on the steering intermediate shaft assembly and steering link assembly.

-

Remove the bolt.

-

Separate the steering intermediate shaft assembly from the steering link assembly.

-

-

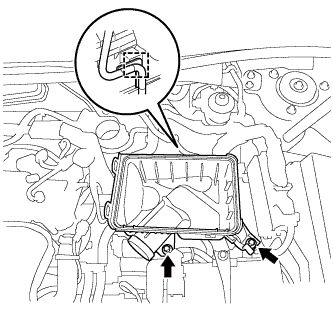

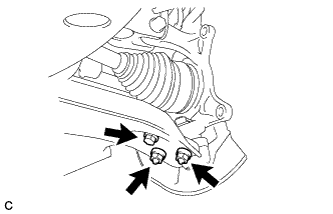

REMOVE FLYWHEEL HOUSING UNDER COVER

-

Remove the flywheel housing under cover.

-

-

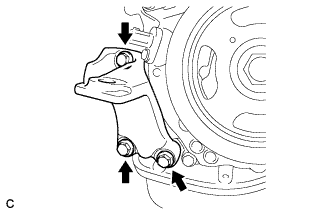

REMOVE DRIVE PLATE AND TORQUE CONVERTER ASSEMBLY SETTING BOLT

-

Turn the crankshaft to gain access to the removal locations of the 6 drive plate and torque converter assembly setting bolts and remove each bolt while holding the crankshaft pulley bolt with a wrench.

-

-

REMOVE ENGINE ASSEMBLY WITH TRANSAXLE

-

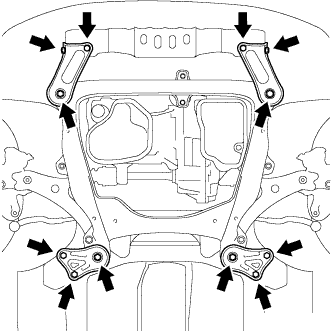

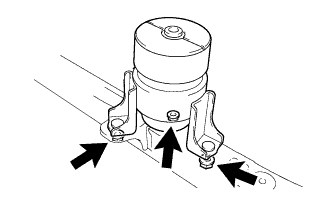

Place height adjustment attachments and plate lift attachments in the positions shown in the illustration and set an engine lifter underneath the engine assembly with transaxle.

Text in Illustration

Attachment Installation Position Note

-

Install height adjustment attachments and plate lift attachments under the engine assembly with transaxle.

-

Securely support the engine assembly to prevent it from turning upside down until it is secured to an engine stand.

-

To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly with transaxle.

-

Do not perform any procedures while the engine assembly is suspended because doing so may cause the engine assembly to drop, resulting in injury. However, the engine assembly needs to be suspended when it is installed or removed from an engine stand.

-

-

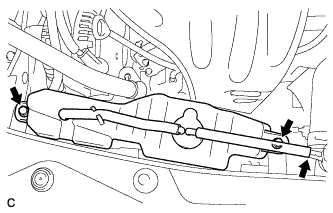

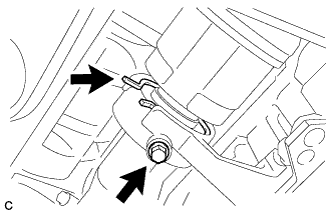

Remove the 4 bolts, 2 nuts and frame side rail plate RH and frame side rail plate LH.

-

Remove the 4 bolts, 2 nuts and front suspension member brace rear RH and front suspension member brace rear LH.

-

Operate the engine lifter and remove the engine assembly with transaxle from the vehicle.

Note

-

Make sure that the engine assembly is clear of all wiring and hoses.

-

While lowering the engine assembly from the vehicle, do not allow it to contact the vehicle.

-

-

Install the engine hangers Click here.

-

Using an engine sling device and engine lift, secure the engine assembly.

-

-

REMOVE ENGINE WIRE

-

Remove the engine wire from the engine assembly with transaxle.

-

-

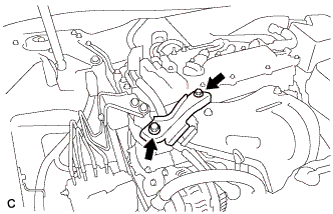

REMOVE V-RIBBED BELT

-

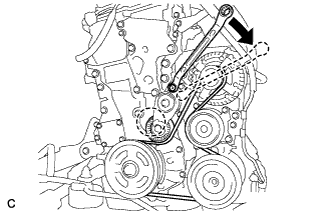

Attach a wrench to the hexagonal portion of the V-ribbed belt tensioner assembly as shown in the illustration, rotate the V-ribbed belt tensioner assembly clockwise, and remove the V-ribbed belt.

-

-

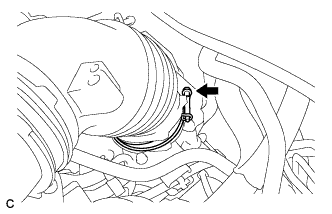

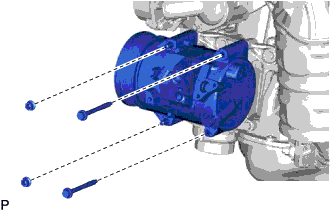

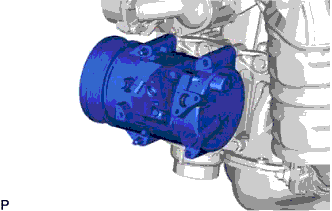

REMOVE COMPRESSOR ASSEMBLY WITH PULLEY

-

Remove the bolt.

-

Disconnect the 2 connectors.

-

Remove the 2 bolts and 2 nuts.

-

Using an E8 "TORX" socket, remove the 2 stud bolts and compressor assembly with pulley.

Tech Tips

Remove the compressor assembly with pulley from the vehicle with the stud bolts remaining in the compressor assembly with pulley.

-

-

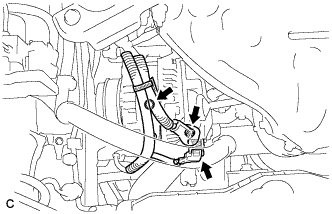

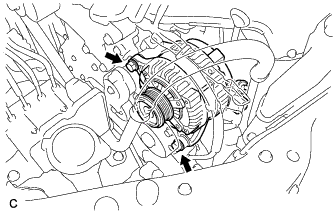

REMOVE GENERATOR ASSEMBLY

-

Disconnect the connector.

-

Remove the cap.

-

Remove the nut and disconnect the wire harness.

-

Remove the bolt and wire harness clamp bracket.

-

Remove the 2 bolts and generator assembly.

-

-

REMOVE FRONT FRAME ASSEMBLY

-

Remove the nut and separate the engine mounting insulator LH.

-

Remove the bolt and separate the front engine mounting insulator.

-

Remove the nut and separate the engine mounting insulator RH.

-

Remove the front frame assembly.

-

Using height adjustment attachments and plate lift attachments, place the engine assembly on a flat level surface.

Note

-

Using height adjustment attachments and plate lift attachments, place the engine assembly with transaxle horizontally.

-

To prevent the oil pan sub-assembly from deforming, do not place any attachments under the oil pan sub-assembly of the engine assembly with transaxle.

-

Using an engine sling device and engine lift, secure the engine assembly before service.

-

-

-

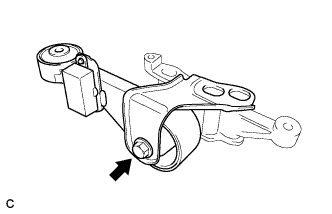

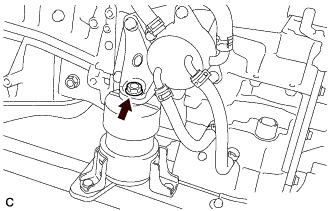

REMOVE FRONT ENGINE MOUNTING INSULATOR

-

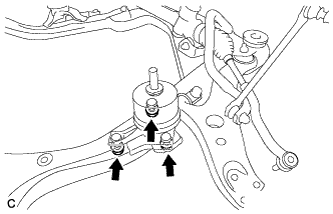

Remove the 3 nuts and front engine mounting insulator.

Tech Tips

Perform this procedure only when replacement of the front engine mounting insulator is necessary.

-

-

REMOVE ENGINE MOUNTING INSULATOR LH

-

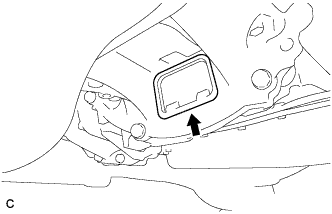

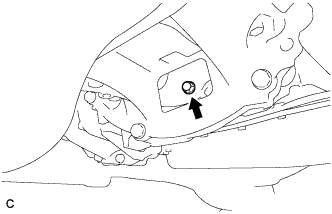

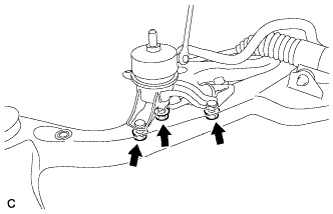

Remove the 2 hole plugs from the front frame assembly.

-

Remove the 3 nuts and engine mounting insulator LH.

Tech Tips

Perform this procedure only when replacement of the engine mounting insulator LH is necessary.

-

-

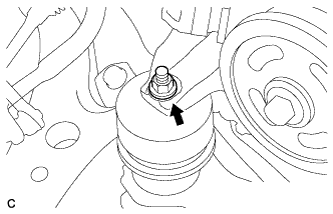

REMOVE ENGINE MOUNTING INSULATOR RH

-

Remove the 2 hole plugs from the front frame assembly.

-

Remove the 3 nuts and engine mounting insulator RH.

Tech Tips

Perform this procedure only when replacement of the engine mounting insulator RH is necessary.

-

-

REMOVE DRIVE SHAFT BEARING BRACKET

-

Remove the 3 bolts and drive shaft bearing bracket.

-

-

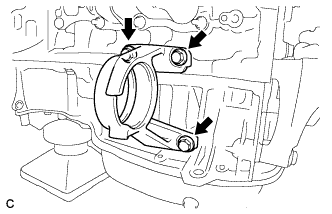

REMOVE ENGINE MOUNTING BRACKET RH

-

Remove the 3 bolts and engine mounting bracket RH.

-

-

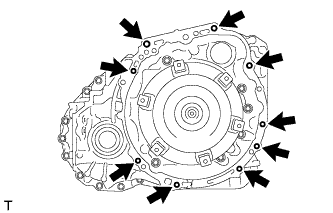

REMOVE AUTOMATIC TRANSAXLE ASSEMBLY

-

Using the transmission jack attachment, set the automatic transaxle assembly on a transmission jack.

Note

-

Secure the automatic transaxle assembly to the transmission jack using a suitable adapter, such as a rope or attachment.

-

To prevent the oil pan from deforming, do not place any attachments onto the oil pan of the automatic transaxle assembly.

-

Hold the engine assembly with a suitable adapter, such as a rope, during the operation.

-

-

Remove the 9 bolts and automatic transaxle assembly.

Note

To prevent damage to the knock pins, do not pry between the automatic transaxle assembly and engine.

-

-

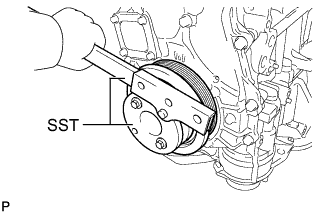

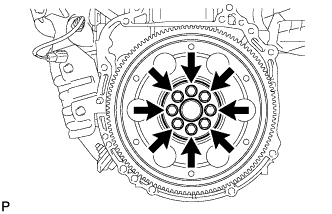

REMOVE DRIVE PLATE AND RING GEAR SUB-ASSEMBLY

-

Using a height adjustable attachment and plate lift attachment, place the engine assembly on a flat level surface.

Note

-

Using a height adjustable attachment and plate lift attachment, place the engine assembly horizontally.

-

To prevent the oil pan sub-assembly from deforming, do not place any attachments onto the oil pan sub-assembly of the engine assembly.

-

Using an engine sling device and engine lift, secure the engine assembly before service.

-

-

Using SST, hold the crankshaft pulley.

- SST

- 09213-54015

- 09330-00021

Tech Tips

SST (Crankshaft pulley holding tool) Fixing bolt part No. : 91551-80650(2 pcs)

-

Remove the 8 bolts, front drive plate spacer, drive plate and ring gear sub-assembly, and rear drive plate spacer.

-

-

INSTALL ENGINE STAND

-

Install the engine to an engine stand with the bolts.

-