HYBRID CONTROL SYSTEM, Diagnostic DTC:P0AA6-526, P0AA6-611, P0AA6-612, P0AA6-613, P0AA6-614

Info Added 2017-08-02 ![]()

| DTC Code | DTC Name |

|---|---|

| P0AA6-526 | Hybrid Battery Voltage System Isolation Fault |

| P0AA6-611 | Hybrid Battery Voltage System Isolation Fault |

| P0AA6-612 | Hybrid Battery Voltage System Isolation Fault |

| P0AA6-613 | Hybrid Battery Voltage System Isolation Fault |

| P0AA6-614 | Hybrid Battery Voltage System Isolation Fault |

DESCRIPTION

The power management control ECU monitors the battery smart unit and detects insulation malfunctions in the high-voltage system.

| DTC No. | INF Code | DTC Detection Condition | Trouble Area |

|---|---|---|---|

| P0AA6 | 526*1 | Insulation resistance between the high-voltage circuit and the body has decreased.*2 |

|

| 611 | Insulation resistance of the high voltage circuit in the air conditioning system has decreased.*3 | Air conditioning system | |

| 612 | Insulation resistance of the HV battery area has decreased.*3 |

|

|

| 613 | Insulation resistance of the transaxle area has decreased.*3 |

|

|

| 614 | Insulation resistance of the high-voltage DC area has decreased.*3 |

|

Tech Tips

-

*1: INF code 526 is stored together with P0AA6.

-

*2: The insulation malfunction detection circuit in the battery voltage sensor monitors the insulation resistance between the high voltage circuits and body. If the insulation resistance decreases, the power management control ECU stores DTC P0AA6-526 and illuminates the MIL first.

-

*3: If the following operations are performed within the same trip after DTC P0AA6-526 is stored, just one of the related DTCs (P0AA6-611, 612, 613 or 614) will be stored.

-

Apply the parking brake firmly.

-

Wait for 1 minute or more with the vehicle stopped, the brake pedal firmly depressed, the power switch on (READY), the shift lever in D and the air conditioning system on (Lo/COOL MAX, blower speed HI), then turn the power switch off and wait for 1 minute or more.

WIRING DIAGRAM

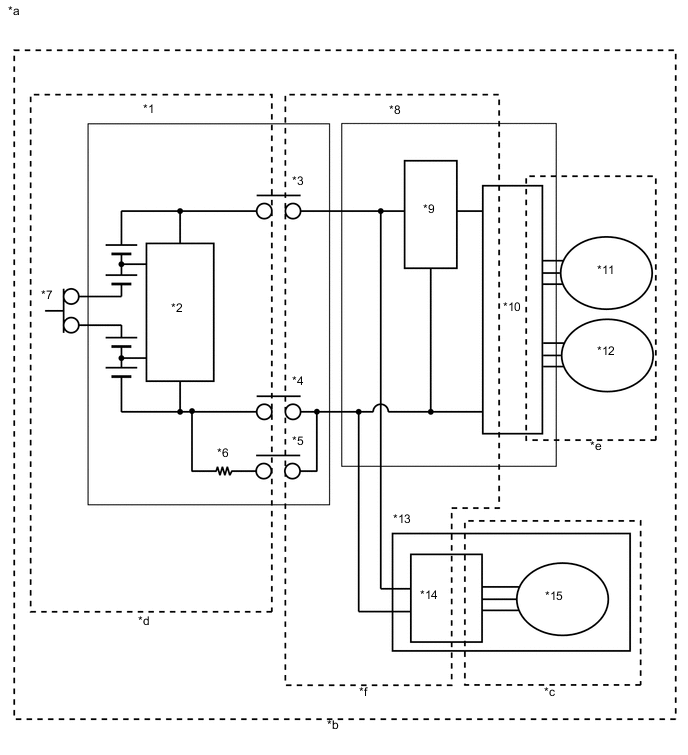

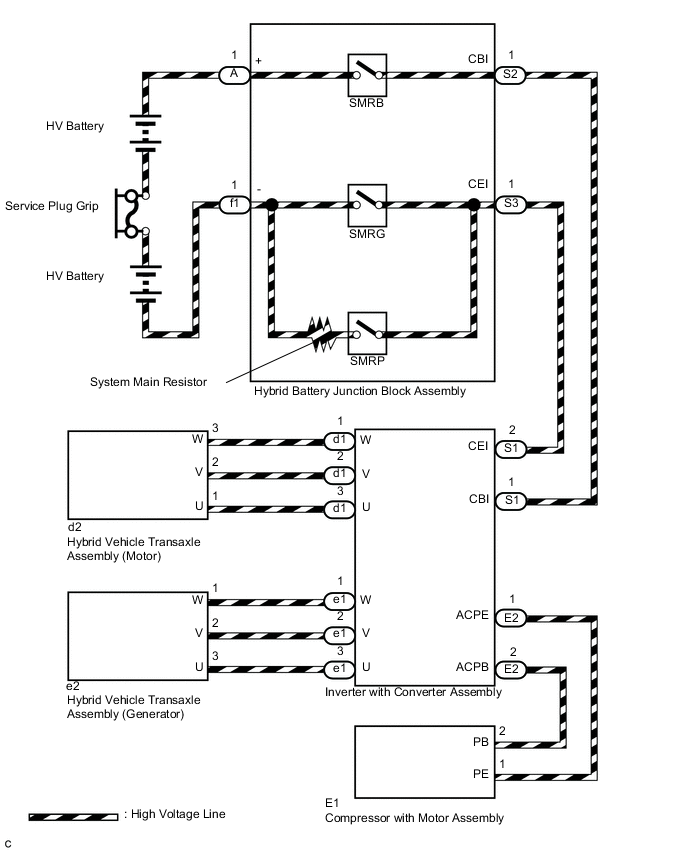

| *1 | HV Battery | *2 | Battery Smart Unit |

| *3 | SMRB | *4 | SMRG |

| *5 | SMRP | *6 | System Main Resistor |

| *7 | Service Plug Grip | *8 | Inverter with Converter Assembly |

| *9 | Boost Converter | *10 | Inverter |

| *11 | MG1 | *12 | MG2 |

| *13 | Compressor with Motor Assembly | *14 | A/C Inverter |

| *15 | A/C Motor | - | - |

| *a | High-voltage Areas | *b | INF Code 526 Vehicle Insulation Resistance Reduction Area |

| *c | INF Code 611 Air Conditioning System Area | *d | INF Code 612 HV Battery Area |

| *e | INF Code 613 Transaxle Area | *f | INF Code 614 High Voltage Direct Current Area |

SYSTEM DESCRIPTION

Tech Tips

If a decrease in insulation resistance cannot be confirmed using a megohmmeter, check the Short Wave Highest Val in the Data List.

-

Characteristics of Short Wave Highest Value

-

The Data List item Short Wave Highest Val and insulation resistance have the relationship shown in the table below. Short Wave Highest Val decreases with a decrease in insulation resistance. However, in some cases, even though the insulation resistance of the vehicle is normal, Short Wave Highest Val may decrease. Therefore, check Short Wave Highest Val under the following conditions:

-

Approximately 1 minute has passed since the power switch was turned on (IG).*1

-

There is no difference between the system voltages ("Power Resource VB", "VL-Voltage before Boosting", and "VH-Voltage after Boosting").*2

Short Wave Highest Value Trouble Area Both conditions (*1 and *2) are met and Short Wave Highest Val is approximately 0 V Since the insulation resistance is close to 0 Ω, there is a strong possibility of interference with a metal object. Both conditions (*1 and *2) are met and Short Wave Highest Val is between 0 and 5 V Since the insulation resistance is several hundred kilo ohms, there is a strong possibility of the presence of fluid such as coolant.

-

-

-

How to Determine Part with Insulation Malfunction

-

Jiggle the high-voltage wire harness to check if the resistance to body ground changes with the position of the wire harness or force applied.

-

Repeatedly operate MG1, MG2 and the compressor with motor assembly. Check that the Short Wave Highest Val does not decrease (for example if the motor stops with foreign matter forming a leak path) when the motor stops, or that the Short Wave Highest Val does not return to normal (for example if foreign matter moves away from the leak path) when the motor rotates.

-

Increase the temperature of MG1 and MG2. Check if the Short Wave Highest Val decreases with the temperature increase.

-

Check that the transaxle fluid is not cloudy and the coolant level in the reserve tank has not dropped. The transaxle fluid will become cloudy when mixed with coolant, resulting in low insulation resistance.

-

CAUTION / NOTICE / HINT

CAUTION:

-

When performing P0AA6 troubleshooting, use either a tool wrapped with vinyl insulation tape or an insulated tool. (It is extremely dangerous when a high-voltage charge passes through a non-insulated tool causing a short.)

-

Before inspecting the high-voltage system or disconnecting the low voltage connector of the inverter with converter assembly, take safety precautions such as wearing insulated gloves and removing the service plug grip to prevent electrical shocks. After removing the service plug grip, put it in your pocket to prevent other technicians from accidentally reconnecting it while you are working on the high-voltage system.

-

After removing the service plug grip, wait for at least 10 minutes before touching any of the high-voltage connectors or terminals. After waiting for 10 minutes, check the voltage at the terminals in the inspection point in the inverter with converter assembly. The voltage should be 0 V before beginning work Click here.

Tech Tips

Waiting for at least 10 minutes is required to discharge the high-voltage capacitor inside the inverter with converter assembly.

-

When disposing of an HV battery, make sure to return it through an authorized collection agent who is capable of handling it safely. If the HV battery is returned via the manufacturer specified route, it will be returned properly and in a safe manner by an authorized collection agent.

Note

After turning the power switch off, waiting time may be required before disconnecting the cable from the negative (-) auxiliary battery terminal. Therefore, make sure to read the disconnecting the cable from the negative (-) auxiliary battery terminal notices before proceeding with work Click here.

Tech Tips

-

If DTC P0AA6 is stored, the hybrid control system cannot be turned on.

-

When measuring insulation resistance using a megohmmeter, set the megohmmeter to 500 V.

-

When measuring insulation resistance using a megohmmeter, measure the resistance while jiggling the high voltage wire harness.

PROCEDURE

-

CHECK DTC OUTPUT (HYBRID CONTROL)

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Check for DTCs.

Result Result Proceed to P0AA6 only is output. A P0AA6 and P0A1D are output. B P0AA6 and P0AA7 are output. C P0AA6 and P0AFC are output. D -

Turn the power switch off.

B

GO TO DTC CHART (P0A1D) Click here

C

GO TO DTC CHART (P0AA7) Click here

D

GO TO DTC CHART (P0AFC) Click here

A

-

-

CHECK INFORMATION CODE

-

Connect the GTS to the DLC3.

-

Turn the power switch on (IG).

-

Enter the following menus: Powertrain / Hybrid Control / Trouble Codes.

-

Access the freeze frame data of DTC P0AA6 and read the INF code.

Note

-

Information codes 611, 612, 613 and 614 are not stored with 526 simultaneously. If a drop in insulation resistance is detected and DTC P0AA6-526 is output, wait for 1 minute with power switch on (READY), the shift lever in D and the air conditioning system on within the same trip, then turn the power switch off and wait for 1 minute to determine the information code (611, 612, 613 or 614).

-

If only DTC P0AA6-526 is output, perform the diagnosis procedure for INF code 526 to inspect all the high voltage circuits.

Result Result Proceed to 526 (decrease in the insulation resistance of the high-voltage circuit) only is output. A 526 and 611 (decrease in the insulation resistance of the air conditioning system area) are output. Refer to the troubleshooting procedure for P0AA6-611 (Air conditioning system) Click here

526 and 612 (decrease in the insulation resistance of the battery area) are output. B 526 and 613 (decrease in the insulation resistance of the transaxle area) are output. C 526 and 614 (decrease in the insulation resistance of the high-voltage DC area) are output. D -

-

Turn the power switch off.

B

CHECK HV BATTERY AREA Click here

C

CHECK INVERTER WITH CONVERTER ASSEMBLY Click here

D

CHECK HIGH VOLTAGE DIRECT CURRENT AREA Click here

A

-

-

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (MOTOR)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

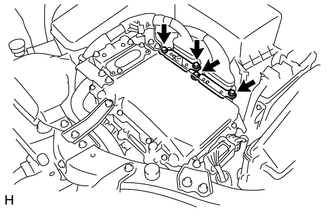

Remove the upper inverter cover (generator cable side) and upper inverter cover (motor cable side) from the inverter with converter assembly.

Tech Tips

Make sure that no foreign matter has entered or contaminated the inverter with converter assembly.

-

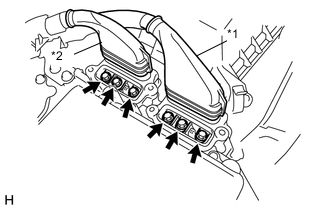

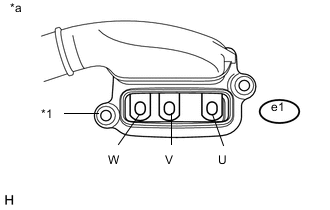

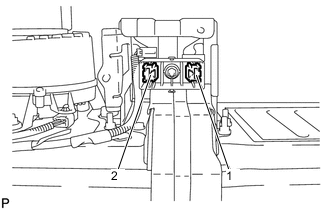

Text in Illustration *1 Generator Cable *2 Motor Cable Disconnect the motor cable and generator cable from the inverter with converter assembly.

-

Connect the cable to the negative (-) auxiliary battery terminal.

Tech Tips

As the insulation resistance may vary when motor (MG2) rotates, perform this inspection while rotating the front wheels.

-

Turn the power switch on (IG).

Note

Turning the power switch on (IG) with the service grip removed causes DTCs to be stored. Clear the DTCs after performing this inspection.

-

With the shift lever in N and lift up the vehicle.

-

Turn the power switch off.

-

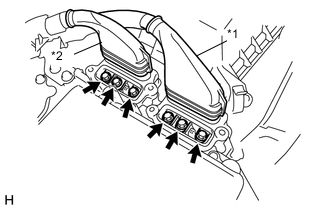

Text in Illustration *1 Shield Ground *a Motor Cable (Inverter with Converter Assembly Side) Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

-

Carefully perform this inspection as motor (MG2) may generate current when the front wheels are rotated by hand.

-

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition d1-1 (W) - Body ground and shield ground Power switch off 100 MΩ or higher d1-2 (V) - Body ground and shield ground Power switch off 100 MΩ or higher d1-3 (U) - Body ground and shield ground Power switch off 100 MΩ or higher -

-

Lower the vehicle and move the shift lever to P position.

-

Disconnect the cable from the negative (-) auxiliary battery terminal.

NG

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

OK

-

-

CHECK HYBRID VEHICLE TRANSAXLE ASSEMBLY (GENERATOR)

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Connect the cable to the negative (-) auxiliary battery terminal.

Tech Tips

As the insulation resistance may vary when generator (MG1) rotates, perform this inspection while rotating the front wheels.

-

Turn the power switch on (IG).

Note

Turning the power switch on (IG) with the service grip removed causes DTCs to be stored. Clear the DTCs after performing this inspection.

-

With the shift lever in N and lift up the vehicle.

-

Turn the power switch off.

-

Text in Illustration *1 Shield Ground *a Generator Cable (Inverter with Converter Assembly Side) Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

-

Carefully perform this inspection as generator (MG1) may generate current when the front wheels are rotated by hand.

-

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition e1-1 (W) - Body ground and shield ground Power switch off 100 MΩ or higher e1-2 (V) - Body ground and shield ground Power switch off 100 MΩ or higher e1-3 (U) - Body ground and shield ground Power switch off 100 MΩ or higher -

-

Lower the vehicle and move the shift lever to P position.

-

Disconnect the cable from the negative (-) auxiliary battery terminal.

NG

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

OK

-

-

CHECK NO. 4 ENGINE WIRE

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

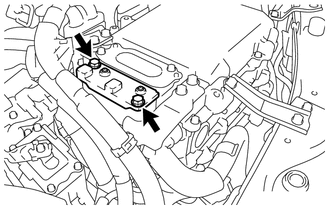

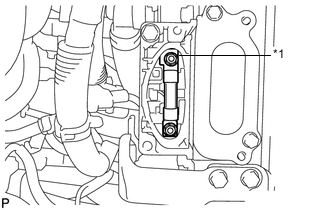

Remove the connector cover assembly from the inverter with converter assembly.

Tech Tips

Make sure that no foreign matter has entered or contaminated the inverter with converter assembly.

-

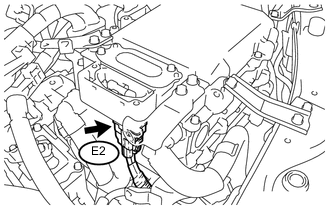

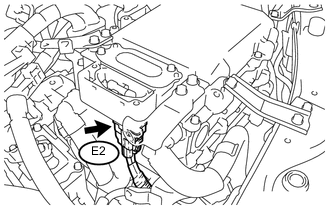

Disconnect the E2 inverter with converter assembly connector.

Tech Tips

Make sure that no foreign matter has entered or contaminated connector E2 of the No. 4 engine wire (air conditioning harness).

-

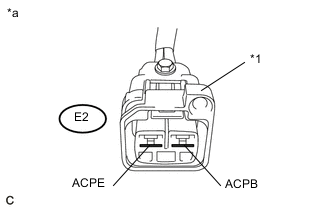

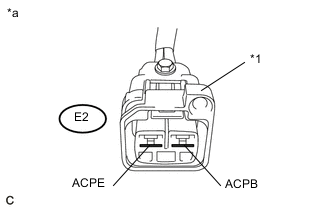

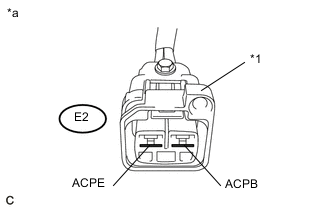

Text in Illustration *1 Shield Ground *a Front view of No. 4 Engine Wire (Air Conditioning Harness) connector

(to Inverter with Converter Assembly)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition E2-1 (ACPE) - Body ground and shield ground Power switch off 3 MΩ or higher E2-2 (ACPB) - Body ground and shield ground Power switch off 3 MΩ or higher

NG

CHECK NO. 4 ENGINE WIRE Click here

OK

-

-

CHECK INVERTER WITH CONVERTER ASSEMBLY

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

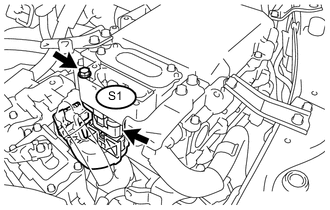

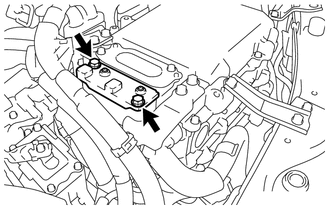

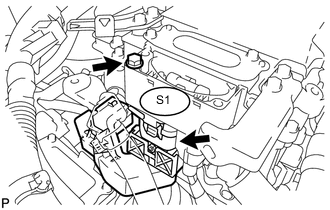

Disconnect the S1 inverter with converter assembly connector.

Tech Tips

Make sure that no foreign matter has entered or contaminated connector S1 of the frame wire.

-

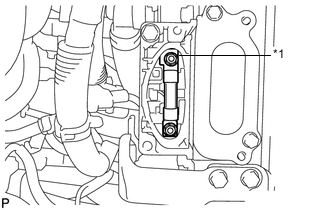

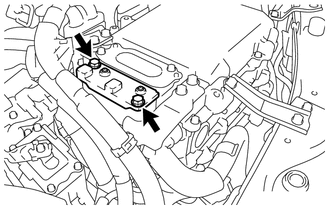

Text in Illustration *1 High Voltage Fuse Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition High voltage fuse terminal - Body ground Power switch off 1 MΩ or higher Tech Tips

Perform this inspection with the motor cable, generator cable and No. 4 engine wire (air conditioning harness) disconnected from the inverter with converter assembly.

NG

REPLACE INVERTER WITH CONVERTER ASSEMBLY Click here

OK

-

-

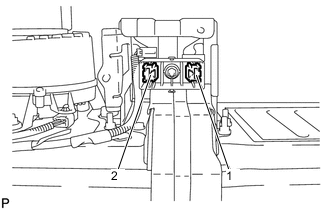

CHECK FRAME WIRE

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

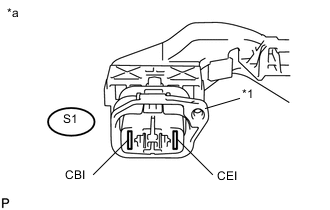

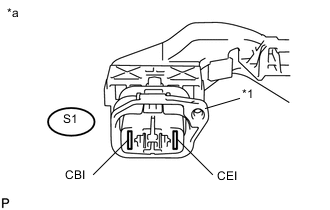

Text in Illustration *1 Shield Ground *a Frame Wire

(Inverter with Converter Assembly Side)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition S1-1 (CBI) - Body ground and shield ground Power switch off 10 MΩ or higher S1-2 (CEI) - Body ground and shield ground Power switch off 10 MΩ or higher Tech Tips

Visually inspect the frame wire for damage. If there is any damage, then this is the likely cause of low insulation resistance.

NG

CHECK FRAME WIRE Click here

OK

-

-

CHECK HV BATTERY AREA

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the No. 2 hybrid vehicle battery shield panel Click here.

-

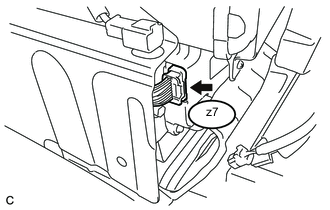

Disconnect the z7 battery smart unit connector.

-

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition 1 - Body ground Power switch off 10 MΩ or higher 2 - Body ground Power switch off 10 MΩ or higher

OK

REPLACE BATTERY SMART UNIT Click here

NG

CHECK HV BATTERY Click here

-

-

CHECK INVERTER WITH CONVERTER ASSEMBLY

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

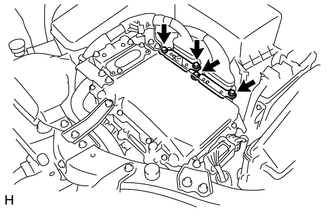

Remove the upper inverter cover (generator cable side) and upper inverter cover (motor cable side) from the inverter with converter assembly.

Tech Tips

Make sure that no foreign matter has entered or contaminated the inverter with converter assembly.

-

Text in Illustration *1 Generator Cable *2 Motor Cable Disconnect the generator cable and motor cable from the inverter with converter assembly.

-

Remove the connector cover assembly from the inverter with converter assembly.

Tech Tips

Make sure that no foreign matter has entered or contaminated the inverter with converter assembly.

-

Text in Illustration *1 High Voltage Fuse Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition High voltage fuse terminal - Body ground Power switch off 1 MΩ or higher Result Result Proceed to NG A OK B

A

REPLACE INVERTER WITH CONVERTER ASSEMBLY Click here

B

REPLACE HYBRID VEHICLE TRANSAXLE ASSEMBLY Click here

-

-

CHECK HIGH VOLTAGE DIRECT CURRENT AREA

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the connector cover assembly from the inverter with converter assembly.

Tech Tips

Make sure that no foreign matter has entered or contaminated the inverter with converter assembly.

-

Disconnect the S1 inverter with converter assembly connector.

Tech Tips

Make sure that no foreign matter has entered or contaminated connector S1 of the frame wire.

-

Text in Illustration *1 Shield Ground *a Frame Wire

(Inverter with Converter Assembly Side)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition S1-1 (CBI) - Body ground and shield ground Power switch off 10 MΩ or higher S1-2 (CEI) - Body ground and shield ground Power switch off 10 MΩ or higher Tech Tips

Visually inspect the frame wire for damage. If there is any damage, then this is the likely cause of low insulation resistance.

NG

CHECK FRAME WIRE Click here

OK

-

-

CHECK NO. 4 ENGINE WIRE

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Disconnect the E2 inverter with converter assembly connector.

-

Text in Illustration *1 Shield Ground *a Front view of No. 4 Engine Wire (Air Conditioning Harness) connector

(to Inverter with Converter Assembly)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition E2-1 (ACPE) - Body ground and shield ground Power switch off 3 MΩ or higher E2-2 (ACPB) - Body ground and shield ground Power switch off 3 MΩ or higher

OK

REPLACE INVERTER WITH CONVERTER ASSEMBLY Click here

NG

-

-

CHECK NO. 4 ENGINE WIRE

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

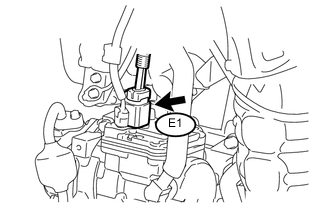

Disconnect the E1 compressor with motor assembly connector Click here.

-

Text in Illustration *1 Shield Ground *a Front view of No. 4 Engine Wire (Air Conditioning Harness) connector

(to Inverter with Converter Assembly)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition E2-1 (ACPE) - Body ground and shield ground Power switch off 10 MΩ or higher E2-2 (ACPB) - Body ground and shield ground Power switch off 10 MΩ or higher

OK

GO TO AIR CONDITIONING SYSTEM (P0AA6-611) Click here

NG

REPLACE NO. 4 ENGINE WIRE

-

-

CHECK FRAME WIRE

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the No. 4 hybrid battery shield panel Click here.

-

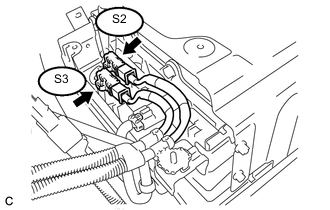

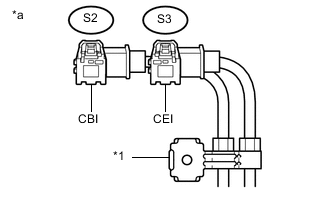

Disconnect the S2 and S3 hybrid battery junction block assembly connectors.

Tech Tips

Make sure that no foreign matter has entered or contaminated the S2 and S3 frame wire connectors.

-

Text in Illustration *1 Shield Ground *a Frame Wire

(Hybrid Battery Junction Block Assembly Side)

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition S3-1 (CEI) - Body ground and shield ground Power switch off 10 MΩ or higher S2-1 (CBI) - Body ground and shield ground Power switch off 10 MΩ or higher Tech Tips

Visually inspect the frame wire for damage. If there is any damage, then this is the likely cause of low insulation resistance.

OK

REPLACE HYBRID BATTERY JUNCTION BLOCK ASSEMBLY Click here

NG

REPLACE FRAME WIRE Click here

-

-

CHECK HV BATTERY

CAUTION:

Be sure to wear insulated gloves.

-

Check that the service plug grip is not installed.

Note

After removing the service plug grip, do not turn the power switch on (READY), unless instructed by the repair manual because this may cause a malfunction.

-

Remove the hybrid battery junction block assembly Click here.

-

Using a megohmmeter set to 500 V, measure the resistance according to the value(s) in the table below.

Note

Be sure to set the megohmmeter to 500 V when performing this test. Using a setting higher than 500 V can result in damage to the component being inspected.

Standard Resistance Tester Connection Condition Specified Condition 1 - Body ground Power switch off 10 MΩ or higher 2 - Body ground Power switch off 10 MΩ or higher

OK

REPLACE HYBRID BATTERY JUNCTION BLOCK ASSEMBLY Click here

NG

REPLACE HV BATTERY Click here

-