FUEL SENDER GAUGE ASSEMBLY INSPECTION

PROCEDURE

-

INSPECT FUEL SENDER GAUGE ASSEMBLY

-

Check the fuel sender gauge assembly output voltage.

-

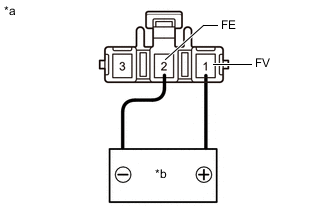

*a Component without harness connected

(Fuel Sender Gauge Assembly)

*b Voltage applied between terminals Apply 5 V between terminals 1 (FV) and 2 (FE).

Note

-

Be careful when connecting the leads, as the fuel sender gauge assembly may be damaged if the leads are connected to the wrong terminals.

-

Do not apply more than 6 V to terminals 1 (FV) and 2 (FE).

Tech Tips

If a stable power supply is not available, use 4 1.2 V nickel-metal hydride batteries or equivalent.

-

-

Measure the voltage according to the value(s) in the table below.

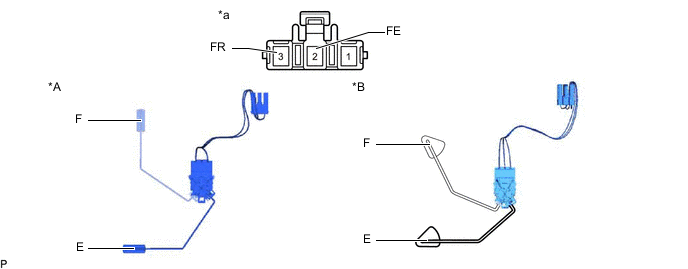

*A for Long Wheelbase *B for Short Wheelbase *a Component without harness connected

(Fuel Sender Gauge Assembly)

- - Standard Voltage Tester Connection Condition Specified Condition 2 (FE) - 3 (FR) Float position is F (upper) 4.25 to 4.61 V* Float position is E (lower) 0.34 to 0.70 V*

-

*: The output voltage changes depending on the voltage applied to the terminals.

Tech Tips

-

Output voltage (F) = (0.850 x Voltage applied to terminals) to (0.922 x Voltage applied to terminals)

-

Output voltage (E) = (0.068 x Voltage applied to terminals) to (0.140 x Voltage applied to terminals)

If the result is not as specified, replace the fuel sender gauge assembly.

-

-

-