ECD SYSTEM, Diagnostic DTC:P2564, P2565

| DTC Code | DTC Name |

|---|---|

| P2564 | Turbocharger/Supercharger Boost Control Position Sensor "A" Circuit Low |

| P2565 | Turbocharger/Supercharger Boost Control Position Sensor "A" Circuit High |

DESCRIPTION

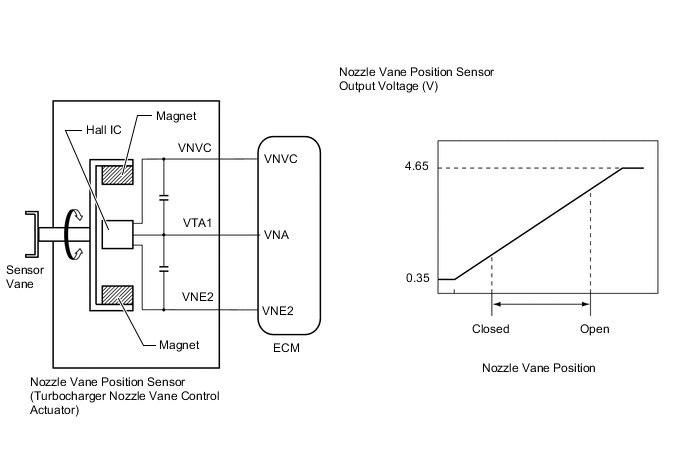

The variable nozzle vane type turbocharger consists primarily of a compressor wheel, turbine wheel, nozzle vane, unison ring, DC motor and nozzle vane position sensor.

The nozzle vane position sensor consists of a Hall IC and a magnetic yoke that rotates in unison with the movement of the linkage that actuates the nozzle vane. The nozzle vane position sensor converts the changes in the magnetic flux that are caused by the rotation of the DC motor (hence, the rotation of the magnetic yoke) into electric signals, and outputs them to the ECM. The ECM determines the actual nozzle vane position from the electric signals in order to calculate the target nozzle vane position.

| DTC No. | Detection Item | DTC Detection Condition | Trouble Area | MIL | Memory |

|---|---|---|---|---|---|

| P2564 | Turbocharger/Supercharger Boost Control Position Sensor "A" Circuit Low | VNA voltage is 0.1 V or less for 2.1 seconds (1 trip detection logic). |

|

Comes on | DTC stored |

| P2565 | Turbocharger/Supercharger Boost Control Position Sensor "A" Circuit High | VNA voltage is 4.9 V or higher for 2.1 seconds (1 trip detection logic). |

|

Comes on | DTC stored |

Tech Tips

If DTC P2564 and/or P2565 is stored due to the nozzle vane being stuck open, the following symptoms may appear:

-

- Lack of power

-

- Vehicle surge or hesitation under light or medium load

CONFIRMATION DRIVING PATTERN

| DTC No. | DTC Detection Drive Pattern |

|---|---|

| P2564 | Ignition switch ON for 2 seconds or more |

| P2565 |

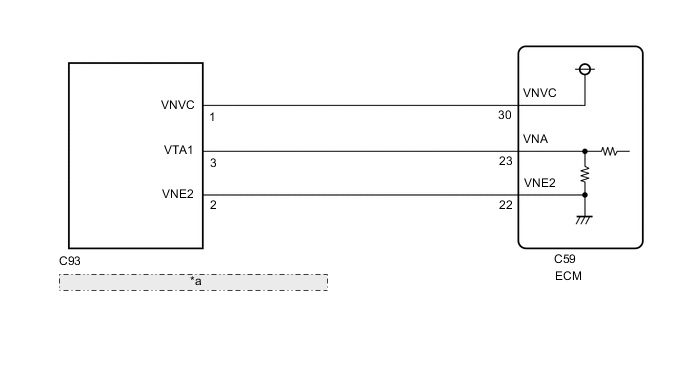

WIRING DIAGRAM

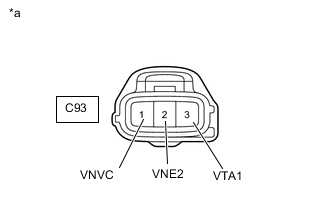

| *a | Nozzle Vane Position Sensor (Turbocharger Nozzle Vane Control Actuator) |

CAUTION / NOTICE / HINT

Note

After replacing the ECM, the new ECM needs registration (Click here ) and initialization Click here.

Tech Tips

Read freeze frame data using the GTS. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

PROCEDURE

-

CHECK TERMINAL VOLTAGE (POWER SOURCE OF NOZZLE VANE POSITION SENSOR)

-

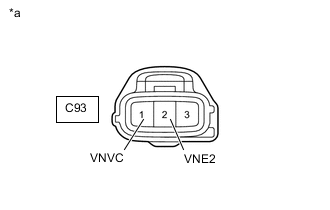

*a Front view of wire harness connector

(to Nozzle Vane Position Sensor)

Disconnect the nozzle vane position sensor connector.

-

Turn the ignition switch to ON.

-

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Condition Specified Condition C93-1 (VNVC) - C93-2 (VNE2) Ignition switch ON 4.5 to 5.5 V -

Reconnect the nozzle vane position sensor connector.

Result Proceed to OK NG

NG

CHECK ECM (POWER SOURCE OF NOZZLE VANE POSITION SENSOR) Click here

OK

-

-

INSPECT NOZZLE VANE POSITION SENSOR (VNA VOLTAGE)

-

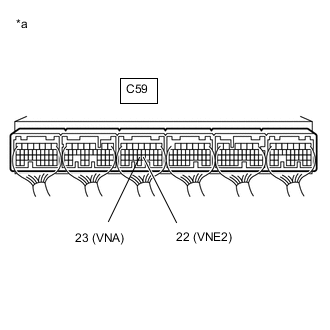

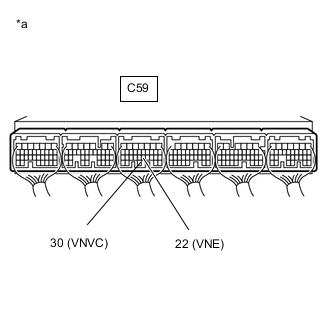

*a Component with harness connected

(ECM)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition C59-23 (VNA) - C59-22 (VNE2) Ignition switch ON 2.3 to 2.7 V Result Proceed to OK NG

OK

GO TO STEP 9 Click here

NG

-

-

CHECK HARNESS AND CONNECTOR (ECM - NOZZLE VANE POSITION SENSOR)

-

Disconnect the nozzle vane position sensor connector.

-

Disconnect the ECM connector.

-

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Condition Specified Condition C93-3 (VTA1) - C59-23 (VNA) Always Below 1 Ω C93-2 (VNE2) - C59-22 (VNE2) Always Below 1 Ω C93-3 (VTA1) or C59-23 (VNA) - Body ground and other terminals Always 10 kΩ or higher C93-2 (VNE2) or C59-22 (VNE2) - Body ground and other terminals Always 10 kΩ or higher -

Reconnect the nozzle vane position sensor connector.

-

Reconnect the ECM connector.

Result Proceed to OK NG

NG

REPAIR OR REPLACE HARNESS OR CONNECTOR Click here

OK

-

-

CHECK ECM (CHECK RESISTANCE)

-

Disconnect the nozzle vane position sensor connector.

-

*a Front view of wire harness connector

(to Nozzle Vane Position Sensor)

Measure the resistance according to the value(s) in the table below.

Standard Resistance Tester Connection Switch Condition Specified Condition C93-1 (VNVC) - C93-3 (VTA1) Ignition switch off No short or open circuit C93-3 (VTA1) - C93-2 (VNE2) -

Reconnect the nozzle vane position sensor connector.

Result Proceed to OK NG

NG

GO TO STEP 9 Click here

OK

-

-

REPLACE TURBOCHARGER NOZZLE VANE CONTROL ACTUATOR (NOZZLE VANE POSITION SENSOR)

-

Replace the turbocharger nozzle vane control actuator.

Result Proceed to NEXT

NEXT

GO TO STEP 10 Click here

-

-

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

Repair or replace the harness or connector.

Result Proceed to NEXT

NEXT

GO TO STEP 10 Click here

-

-

CHECK ECM (POWER SOURCE OF NOZZLE VANE POSITION SENSOR)

-

*a Component with harness connected

(ECM)

Measure the voltage according to the value(s) in the table below.

Standard Voltage Tester Connection Switch Condition Specified Condition C59-30 (VNVC) - C59-22 (VNE2) Ignition switch ON 4.5 to 5.5 V Result Proceed to OK NG

NG

REPLACE ECM Click here

OK

-

-

REPAIR OR REPLACE HARNESS OR CONNECTOR

-

Repair or replace the harness or connector.

Result Proceed to NEXT

NEXT

GO TO STEP 10 Click here

-

-

REPLACE ECM

-

Replace the ECM.

Result Proceed to NEXT

NEXT

-

-

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

-

Connect the GTS to the DLC3.

-

Clear the DTCs.

Powertrain > Engine and ECT > Clear DTCs -

Turn the ignition switch off.

-

Turn the ignition switch off and leave the vehicle for 15 seconds.

-

Turn the ignition switch to ON for 1 second.

-

Confirm that the DTC is not output again.

Tech Tips

Perform the following procedure using the GTS to determine whether or not the DTC judgment has been carried out.

-

Enter the following menus: Powertrain / Engine and ECT / Utility / All Readiness.

Powertrain > Engine and ECT > UtilityTester Display All Readiness -

Input DTC P2564 and/or P2565.

-

Check that STATUS is NORMAL. If STATUS is INCOMPLETE or N/A, idle the engine.

Result Proceed to NEXT -

NEXT

END

-