ECD SYSTEM DATA LIST / ACTIVE TEST

-

DATA LIST

Tech Tips

Using the GTS to read the Data List allows the values or states of switches, sensors, actuators and other items to be read without removing any parts. This non-intrusive inspection can be very useful because intermittent conditions or signals may be discovered before parts or wiring is disturbed. Reading the Data List information early in troubleshooting is one way to save diagnostic time.

Note

In the table below, the values listed under "Normal Condition" are reference values. Do not depend solely on these reference values when deciding whether a part is faulty or not.

-

Warm up the engine.

-

Turn the ignition switch off.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Start the engine.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine / Data List.

Tech Tips

-

To display the list box, press the pull down menu button next to "Primary".

Then select a measurement group.

-

When you select a measurement group, the ECU data belonging to that group is displayed.

-

Measurement Group List / Description

-

All Data / All data

-

Primary / -

-

Engine Control / Engine control system related data

-

Vehicle Information / Vehicle information

-

Monitor Status / Monitor status related data

-

AF Control System / Not Applicable

-

Catalytic Converter / Not Applicable

-

Evaporative / Not Applicable

-

A/T / Automatic transmission system related data

-

ETCS / Not Applicable

-

Misfire / Not Applicable

-

Compression / Data used during "Check the Cylinder Compression" Active Test

-

HC Absorber System / Not Applicable

-

Diesel Driving / Driving condition data

-

Diesel Injection / Fuel system related data

-

Diesel Throttle / Diesel throttle system related data

-

Diesel VN Turbo / VN turbo related data

-

Diesel Exhaust / Exhaust system related data

-

Diesel Starting / "Difficult to start" related data

-

Diesel Rough / "Rough idle" related data

-

Diesel Power / "Lack of power" related data

-

-

Check the values by referring to the table below.

Tech Tips

"Result of real-vehicle check" is the assessment of one vehicle. Use it only for reference.

-

-

Various Vehicle Conditions 1 (All Data)

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Vehicle Speed Vehicle speed Min.: 0 km/h,

Max.: 255 km/h

Actual vehicle speed Cause of Out of Range:

-

Speed sensor

-

Speed sensor circuit

Target Idle Engine Speed Target Idling Engine Speed Min.: 0 rpm,

Max.: 10000 rpm

- - Engine Speed Engine speed Min.: 0 rpm,

Max.: 6000 rpm

-

50 to 400 rpm: Cranking

-

700 to 800 rpm: Idling with warm engine

When the crankshaft position sensor is malfunctioning, "Engine Speed" is approximately 0 or varies greatly from the actual engine speed.

Cause of Out of Range:

-

Crankshaft position sensor

-

Crankshaft position sensor circuit

Calculate Load Load calculated by ECM Min.: 0%,

Max.: 100%

-

Idling: 11.4 to 16.4%

-

Running without load (2500 rpm): 13.1 to 18.9%

Calculated load = (Final injection volume / max. injection volume at current engine speed) x 100.

Cause of Out of Range:

Malfunction in which turbo pressure or Mass Air Flow decreases.

MAF Air flow rate from mass airflow meter Min.: 0 gm/sec,

Max.: 400 gm/sec

-

7 to 21 gm/sec: Idling

-

36 to 60 gm/sec: Running without load (2,500 rpm)

-

Based on the MAF, the ECM controls the fuel injection volume, injection timing, etc.

-

If the value is always approximately 0 gm/sec:

-

Mass air flow meter power source circuit is open.

-

VG circuit is open or shorted.

-

If the value is always 167.5 gm/sec or more:

-

EVG circuit is open.

Cause of Out of Range:

-

Mass air flow meter

-

Mass air flow meter circuit

-

Intake related clog or leak

-

Exhaust related clog

-

Turbocharger sub-assembly

-

Leak or clog in passages for turbocharger

Symptoms when out of range:

Rough idling

Atmosphere Pressure Atmospheric pressure value Min.: 0 kPa,

Max.: 255 kPa

Actual atmospheric pressure

-

With the ignition switch to ON, when the difference between the atmospheric pressure sensor and intake manifold absolute pressure is 10 kPa or more, there is a malfunction in one of the sensors.

-

With the ignition switch to ON, when the atmospheric pressure is 0 kPa or 140 kPa, there is a malfunction in the sensor circuit.

-

Standard atmospheric pressure: 101 kPa.

-

For every 100 m increase in elevation, pressure drops by 1 kPa.

This varies by weather (high atmospheric pressure, low atmospheric pressure).

Cause of Out of Range:

Atmospheric pressure sensor itself has failed (atmospheric pressure sensor is inside the ECM).

MAP Absolute pressure inside intake manifold Min.: 0 kPa,

Max.: 255 kPa

-

85 to 100 kPa: Idling

-

99 to 135 kPa: Engine running at 3000 rpm

-

When the ignition switch is on or the vehicle is idling, the intake manifold absolute pressure and atmospheric pressure are approximately the same (standard atmospheric pressure = 101 kPa).

Above approximately 1500 rpm, the turbo becomes effective and the pressure becomes higher than atmospheric pressure.

-

Inspect while comparing with "Target Booster Pressure".

-

With the accelerator fully open, if the actual manifold absolute pressure (MAP) is low compared to the target booster pressure by at least 20 kPa for 5 seconds or more, a feeling of insufficient power will occur.

Cause of Out of Range:

-

Manifold absolute pressure sensor

-

Intake related clog or leak

-

Exhaust related clog

-

Turbocharger sub-assembly

-

Leak or clog in passages for turbocharger

-

Exhaust leak

-

Throttle valve stuck closed

Symptoms when out of range:

Lack of power

Coolant Temp Engine coolant temperature Min.: -40°C,

Max.: 140°C

After warming up engine: 70 to 90°C (158 to 194°F)

-

If the value is -40°C (-40°F) or 140°C (284°F), the sensor circuit is open or shorted.

-

After a long soak, the coolant temperature, intake air temperature and ambient temperature are approximately equal.

Cause of Out of Range:

-

Engine coolant temperature sensor

-

Thermostat

Symptoms when out of range:

Difficulty starting when engine is cold, rough idle, black smoke, lack of power.

Intake Air Intake air temperature Min.: -40°C,

Max.: 140°C

Equivalent to temperature at location of mass air flow meter

-

After a long soak, the engine coolant temperature, intake air temperature and ambient temperature are approximately equal.

-

If the value is -40°C (-40°F) or 140°C (284°F), the sensor circuit is open or shorted.

Cause of Out of Range:

Intake air temperature sensor

Engine Run Time Engine run time Min.: 0 sec.,

Max.: 65535 sec.

Time after the ignition switch turned on Time passed since the ignition switch was turned on. Initial Engine Coolant Temp Initial engine coolant temperature Min.: -40°C,

Max.: 120°C

Engine coolant temperature when engine started For freeze frame data, this tells whether the malfunction happened at a cold start or with a warm engine. Initial Intake Air Temp Initial intake air temperature Min.: -40°C,

Max.: 120°C

Intake air temperature when engine started - Battery Voltage Battery voltage Min.: 0 V,

Max.: 15 V

11 to 14 V If 11 V or less, characteristics of some electrical components change.

Symptoms when out of range:

If 5 V or less, starting becomes difficult

Alternate Duty Ratio Alternator generation duty ratio Min.: 0%,

Max.: 100%

-

No electrical load at idling: 20 to 60%

-

High electrical load at idling: 100%

-

This is outputs the alternator generation duty and is used to determine the electrical load.

-

Can be used to determine whether a higher-than-normal injection volume at idle, etc. is due to electrical loading or from some other source.

For example, when the duty is not high but the idling injection volume is high, there is injector volume degradation or high engine friction.

-

Can be used for judging whether or not a malfunctioning component in the electrical system is generating continual generation requests (e.g., battery deterioration is causing an unending full recharge request, etc.). Regardless of whether or not an auxiliary device like the A/C or heater is active, if the alternator duty is always at the maximum value, there is an electrical system abnormality, like battery deterioration.

Cause of Out of Range:

-

Battery deterioration

-

Alternator malfunction

-

Electric load, lights, etc.

Glow Relay Request Status of the glow relay request ON or OFF - - Glow Indicator Supported Glow indicator support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Glow Indicator Status of the glow indicator ON or OFF - - Accel Position Accelerator position status Min.: 0%,

Max.: 100%

-

Accelerator pedal released: 0%

-

Accelerator pedal fully depressed: 100%

-

"Accel Position" is the accelerator opening amount (%) for engine control use.

-

When the accelerator pedal position sensor output itself (Accel Sens. No.1 Volt %, Accel Sens. No.2 Volt %) is in the normal range, another actuator malfunction has caused the fail-safe function to restrict the accelerator.

-

Without cruise, ECT or VSC requests, and without accelerator restriction by the fail-safe function, this is adjusted in proportion to the amount the accelerator pedal is depressed by the driver.

-

Accelerator pedal released: 0%

-

Accelerator pedal fully depressed: 100%

Accel Sens. No.1 Volt % Accelerator position No. 1 Min.: 0%,

Max.: 100%

-

Acceleratorpedal released:10 to 22%

-

Acceleratorpedal fullydepressed:52 to 90%

Read value with ignition switch ON (do not start engine).

Tech Tips

This is used only for diagnosing malfunctions in the accelerator pedal position sensor.

Under normal conditions, it is sufficient to only check the final accelerator opening angle value "Accel Position".

Accel Sens. No.2 Volt % Acceleratorposition No. 2 Min.: 0%,

Max.: 100%

-

Accelerator pedal released :24 to 40%

-

Accelerator pedal fully depressed: 68 to 99%

Read value with ignition switch ON (do not start engine).

Tech Tips

This is used only for diagnosing malfunctions in the accelerator pedal position sensor.

Under normal conditions, it is sufficient to only check the final accelerator opening angle value "Accel Position".

-

-

Diesel Throttle System

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Target Throttle Position Supported Target throttle position support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Target Throttle Position Target throttle position Min.: -128%,

Max.: 127%

-

Throttle valve fully opened: 100%

-

Throttle valve fully closed: 0%

If there is a malfunction of the throttle actuator, compare the target and actual throttle position values for troubleshooting. Target Throttle Position #2 Supported Target throttle position (No. 2) support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Target Throttle Position #2 Target No. 2 throttle position Min.: -128%,

Max.: 127%

- - Actual Throttle Position Supported Actual throttle position support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Actual Throttle Position Actual diesel throttle position Min.: -20%,

Max.: 120%

Idling after engine warmed-up: 10 to 40% Closing percentage of the throttle valve.

-

Fully closed: 100%.

-

Fully open: 0%.

Tech Tips

There is no connection with the accelerator. However, under full load, the throttle is usually fully open (0%).

Symptoms when out of range:

-

Stuck closed: Engine stall, difficult to start, lack of power, black smoke, rough idle

-

Stuck open: Loud turbocharging sound, bad vibration when engine is stopped

-

When ECM detects a malfunction of the diesel throttle (MIL on), engine power is restricted so that the vehicle can drive with a maximum speed of 80 to 100 km/h.

Actual Throttle Position #2 Supported Actual No. 2 throttle position support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Actual Throttle Position #2 Actual No. 2 throttle position Min.: -20%,

Max.: 120%

- - Throttle Motor DUTY Throttle motor duty Min.: 0%,

Max.: 100%

- When the moving force to open and close the diesel throttle valve increases, the value of the Throttle Motor Duty increases. Throttle Close Learning Val. Throttle fully closed position learned value Min.: 0 deg,

Max.: 84 deg

11 to 21 deg

-

When the ignition switch is turned from on to off and 5 seconds elapse, learning of "Throttle Close Learning Val." will be complete.

-

When "Throttle Close Learning Val." is outside of the normal range, a foreign object may lodged in the throttle valve.

-

If the value is stuck at the upper limit of 21.25 deg, there is a chance that a malfunction is present.

However, as the initial value for the learned value is 21.25 deg, it is necessary to check the value after learning is completed.

Throttle Sensor Volt % Absolute throttle position sensor Min.: 0%,

Max.: 100%

-

Ignition switch ON: 60 to 80%

-

Warmed-up and idling: 10 to 80%

-

Throttle position sensor output voltage is converted using 5 V = 100%.

-

When fully closed: 14%.

-

When fully open: 70%.

-

When the ignition switch is turned from off to ON, the throttle valve fully opens once.

-

When the ignition switch is turned from ON to off, the throttle valve fully closes once.

Symptoms when out of range:

-

Stuck closed: Engine stall, difficult to start, rough idling, lack of power, black smoke, white smoke

-

Stuck open: Loud turbocharging sound, bad vibration when engine is stopped

-

When the ECM detects a malfunction with the diesel throttle (MIL on), engine power is restricted but city driving is possible.

-

-

Diesel Injection System

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Injection Volume Injection volume Min.: 0 mm3/st,

Max.: 1279.98 mm3/st

Idling: 3.0 to 10 mm3/st

-

Injection amount for each combustion.

-

If injector assemblies are clogged fuel quality is poor, the fuel filter element assembly is clogged, or engine friction increases, "Injection Volume" will increase.

-

If there is a malfunction due to low turbocharger pressure or a low intake air volume, the injection volume is limited and there is a lack of power.

Inj. FB Vol. for Idle Idle stability status integral control volume Min.: -80 mm3/st,

Max.: 79 mm3/st

-10 to 10 mm3/st

-

When the actual engine speed does not match the target idling speed, this corrects the injection volume.

If this item displays 10 mm3/st or more or -10 mm3/st or less even with the engine completely warmed up and the air conditioning and other electrical loads off, the internal parts of the engine may be damaged, or the fuel injection system or other auxiliary components may be malfunctioning.

-

Only calculated and reflected at idle.

Symptoms when out of range:

Engine friction problem, compressionproblem or injector breakdown

Inj Vol Feedback Learning Injection volume feedback learning value Min.: -10 mm3/st,

Max.: 9.92 mm3/st

- - Injection Feedback Val #1 Injection volume correction for each cylinder Min.: -10 mm3/st,

Max.: 10 mm3/st

Idling: -3.0 to 3.0 mm3/st

-

When idling after warmup, the injection amount for each cylinder is corrected to optimize the difference between the engine speed of each cylinder.

Example: For cylinders that are slowing the engine speed compared to other cylinders, the injection volume is increased.

-

"Injection Feedback Val" more than 3.0 mm3/st: Injector breakdown is causing injection volume deviation, or insufficient compression is causing poor combustion.

-

Even if "Injection Feedback Val" for a cylinder is less than -3.0 mm3/st, the cylinder with this value does not necessarily have a problem.

Tech Tips

-

The ECM adjusts each cylinder so that the average "Injection Feedback Val" of the 4 cylinders is approximately 0 mm3/st.

-

If more than one cylinder has a positive correction value, a normal cylinder may have a value less than -3.0 mm3/st.

Cause of Out of Range:

-

Injector clogging

-

Injector deterioration

-

Decrease in cylindercompression

-

Injector compensation code is incorrectly set (forgot to input code after replacement or made mistake during setting of code after replacing ECM with one from another vehicle)

Symptoms when out of range:

Rough idling, black smoke, white smoke, poor driveability, lack of power, abnormal combustion noise, difficult to start

Injection Feedback Val #2 Injection volume correction for each cylinder Min.: -10 mm3/st,

Max.: 10 mm3/st

Idling: -3.0 to 3.0 mm3/st

-

When idling after warmup, the injection amount for each cylinder is corrected to optimize the difference between the engine speed of each cylinder.

Example: For cylinders that are slowing the engine speed compared to other cylinders, the injection volume is increased.

-

"Injection Feedback Val" more than 3.0 mm3/st: Injector breakdown is causing injection volume deviation, or insufficient compression is causing poor combustion.

-

Even if "Injection Feedback Val" for a cylinder is less than -3.0 mm3/st, the cylinder with this value does not necessarily have a problem.

Tech Tips

-

The ECM adjusts each cylinder so that the average "Injection Feedback Val" of the 4 cylinders is approximately 0 mm3/st.

-

If more than one cylinder has a positive correction value, a normal cylinder may have a value less than -3.0 mm3/st.

Cause of Out of Range:

-

Injector clogging

-

Injector deterioration

-

Decrease in cylindercompression

-

Injector compensation code is incorrectly set (forgot to input code after replacement or made mistake during setting of code after replacing ECM with one from another vehicle)

Symptoms when out of range:

Rough idling, black smoke, white smoke, poor driveability, lack of power, abnormal combustion noise, difficult to start

Injection Feedback Val #3 Injection volume correction for each cylinder Min.: -10 mm3/st,

Max.: 10 mm3/st

Idling: -3.0 to 3.0 mm3/st

-

When idling after warmup, the injection amount for each cylinder is corrected to optimize the difference between the engine speed of each cylinder.

Example: For cylinders that are slowing the engine speed compared to other cylinders, the injection volume is increased.

-

"Injection Feedback Val" more than 3.0 mm3/st: Injector breakdown is causing injection volume deviation, or insufficient compression is causing poor combustion.

-

Even if "Injection Feedback Val" for a cylinder is less than -3.0 mm3/st, the cylinder with this value does not necessarily have a problem.

Tech Tips

-

The ECM adjusts each cylinder so that the average "Injection Feedback Val" of the 4 cylinders is approximately 0 mm3/st.

-

If more than one cylinder has a positive correction value, a normal cylinder may have a value less than -3.0 mm3/st.

Cause of Out of Range:

-

Injector clogging

-

Injector deterioration

-

Decrease in cylindercompression

-

Injector compensation code is incorrectly set (forgot to input code after replacement or made mistake during setting of code after replacing ECM with one from another vehicle)

Symptoms when out of range:

Rough idling, black smoke, white smoke, poor driveability, lack of power, abnormal combustion noise, difficult to start

Injection Feedback Val #4 Injection volume correction for each cylinder Min.: -10 mm3/st,

Max.: 10 mm3/st

Idling: -3.0 to 3.0 mm3/st

-

When idling after warmup, the injection amount for each cylinder is corrected to optimize the difference between the engine speed of each cylinder.

Example: For cylinders that are slowing the engine speed compared to other cylinders, the injection volume is increased.

-

"Injection Feedback Val" more than 3.0 mm3/st: Injector breakdown is causing injection volume deviation, or insufficient compression is causing poor combustion.

-

Even if "Injection Feedback Val" for a cylinder is less than -3.0 mm3/st, the cylinder with this value does not necessarily have a problem.

Tech Tips

-

The ECM adjusts each cylinder so that the average "Injection Feedback Val" of the 4 cylinders is approximately 0 mm3/st.

-

If more than one cylinder has a positive correction value, a normal cylinder may have a value less than -3.0 mm3/st.

Cause of Out of Range:

-

Injector clogging

-

Injector deterioration

-

Decrease in cylindercompression

-

Injector compensation code is incorrectly set (forgot to input code after replacement or made mistake during setting of code after replacing ECM with one from another vehicle)

Symptoms when out of range:

Rough idling, black smoke, white smoke, poor driveability, lack of power, abnormal combustion noise, difficult to start

Pilot 1 Injection Period Pilot 1 injection period Min.: 0 μs,

Max.: 65535 μs

Idling: 370 to 470 μs Check to see if "Pilot 1 Injection Period" is not zero when symptoms occur.

Symptoms when out of range:

Combustion noise, poor driveability, white smoke

Pilot 2 Injection Period Pilot 2 injection period Min.: 0 μs,

Max.: 65535 μs

Idling: 370 to 470 μs Check to see if "Pilot 2 Injection Period" is not zero when symptoms occur.

Symptoms when out of range:

Combustion noise, poor driveability, white smoke

Main Injection Period Main injection period Min.: 0 μs,

Max.: 65535 μs

Idling: 450 to 650 μs

-

When the fuel pressure becomes 15000 kPa or less, "Main Injection Period" is set to 0.

-

When the engine will not start, confirm that injection is performed.

-

When P0093, P0627 or P0200 is stored, there is an engine stall request. At that time, "Main Injection Period" equals 0.

Tech Tips

As the engine stalls 1 minute after the MIL illuminates, freeze frame data cannot be checked.

After Injection Period After injection period Min.: 0 μs,

Max.: 65535 μs

- Check to see if "After Injection Period" is not zero when the following symptoms occur:

Black smoke, poor driveability.

Pilot 1 Injection Timing Pilot 1 injection timing Min.: -70°CA,

Max.: 20°CA

Idling after engine warmed up and vehicle under normal atmospheric pressure: -16 to -12°CA - Pilot 2 Injection Timing Pilot 2 injection timing Min.: -50°CA,

Max.: 20°CA

Idling after engine warmed up and vehicle under normal atmospheric pressure: -12 to -6°CA - Main Injection Timing Main injection timing Min.: -90°CA,

Max.: 90°CA

Idling after engine warmed up and vehicle under normal atmospheric pressure: 3 to 7°CA Use "Main Injection Timing" to check poor drivability when the following symptoms are present: Bad injection timing, black smoke, and white smoke. After Injection Timing After injection timing Min.: -10°CA,

Max.: 50°CA

- - Pilot Quantity Learning State of "Pilot Quantity Learning" Standby / Wait / Learn / Stop / Comple - If "Pilot Quantity Learning" is incomplete, the MIL illuminates and DTC P1601 is stored. Injector Pilot Quantity Learning Status of the injector pilot quantity learning Ready or NG - - Actuator Pilot Quantity Learning Status of the actuator pilot quantity learning Ready or NG - - Temperature Pilot Quantity Learning Status of the temperature pilot quantity learning Ready or NG - - Catalyst Pilot Quantity Learning Status of the catalyst pilot quantity learning Ready or NG - - Injection Pressure Correction Injection pressure feedback compensation volume Min.: -500 mm3/st,

Max.: 780 mm3/st

-400 to 400 mm3/st atstandard temperature

-

When the (actual) fuel pressure is equal to the target fuel pressure, this value becomes 0.

-

This indicator can be used for diagnosing supply pump related malfunctions.

-

When this value (absolute value) is large, it indicates that the difference between the actual and target fuel pressure is also large.

A positive value indicates that the pressure feed is being increased due to insufficient pressure. A negative value indicates that pressure is being reduced due to excessive rail pressure.

When the suction control valve does not close properly, it causes rail overpressure, and this value slip to the negative volume side.

Cause of Out of Range:

-

Suction control valve malfunction

-

Clogged fuel filter element assembly

Injection EDU Relay Request Status of the EDU relayrequest ON or OFF ON: EDU relay ON - Target Common Rail Pressure Supported Target common rail pressure support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Target Common Rail Pressure Target common rail pressure Min.: 0 kPa,

Max.: 250000 kPa

30000 to 160000 kPa when engine running

-

Inspect the (actual) fuel pressure, comparing it with the common rail target value.

-

Considered normal when the actual fuel pressure is within 5000 kPa of the target fuel pressure under stable conditions when idling after warm up the engine.

Common Rail Pressure Supported Common rail pressure support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Common Rail Pressure Actual common rail pressure Min.: 0 kPa,

Max.: 250000 kPa

Idling: 28000 to 40000 kPa

-

Common rail pressure is the actual common rail fuel pressure.

-

Inspect by comparing the fuel pressure with the target fuel pressure.

-

When in a stable condition such as when idling after warm up the engine, the fuel pressure is within 5000 kPa of the target fuel pressure.

-

The ECM uses fuel pressure for feedback control of the target fuel pressure via the supply pump.

The injection amount is determined based on the injection timing and fuel pressure.

-

For startup, at least 25000 kPa of fuel pressure is needed (take care as there is a response lag when the pressure rises).

-

When the fuel pressure is below 25000 kPa, it may cause rough idling.

-

When the fuel pressure has decreased by 20000 kPa from the target fuel pressure, there may be a lack of power.

-

If the actual fuel pressure is 5000 kPa higher than the target fuel pressure, P1229 will be stored. When it is lower than the target fuel pressure, a lack of power will occur, but a DTC will not be stored.

-

When the fuel pressure is higher than 200000 kPa, DTC P0088 will be stored.

Cause of Out of Range:

-

Fuel supply pump assembly

-

High pressure pipes

-

Fuel pressure sensor

-

Injector assembly

-

Feed pump (fuel supply pump assembly)

-

Fuel filter element assembly

-

Pressure limiter

-

Air in the fuel pipes

-

Lack of fuel

Symptoms when out of range:

Difficult to start, poor driveability, lack of power, abnormal combustion noise

Fuel Temperature Supported Fuel temperature support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Fuel Temperature Fuel temperature Min.: -40°C,

Max.: 140°C

Actual fuel temperature After fully cold soaking the engine, the fuel temperature is the same as the outside air temperature. Target Pump SCV Current Final pump current target value Min.: 0 mA,

Max.: 4000 mA

Idling: 923 to 1123 mA

-

ECU-calculated value for the suction control valve actuation target current.

-

Value is large when a high fuel pressure is desired.

-

Normally, the value is between 800 and 2500 mA.

-

If the value is stuck at 3000 mA or higher, it indicates that the operation is poor (poor movement due to deposits, etc.).

-

When this deviates from the standard value, it indicates that for some reason, even though the pump is running hard, the actual fuel pressure is inconsistent with the target fuel pressure.

Cause of Out of Range:

-

Suction control valve malfunction

-

Clogged fuel filter element assembly

Symptoms when out of range:

Difficulty starting, lack of power or rough idling

Pump SCV Learning Value Pump SCV learning value Min.: -4096 mA,

Max.: 4095.8 mA

Min.: -100 mA

Max.: 100 mA

If the value is stuck at 200 mA or higher or -200 mA or less, it indicates that the operation is poor (poor movement due to deposits, etc.).

Cause of Out of Range:

-

Suction control valve malfunction

-

Clogged fuel filter element sub-assembly

Symptoms when out of range:

Difficulty starting, lack of power or rough idling

Pump SCV Status Pump SCV Status ON or OFF - - Pump SCV Duty Request Pump SCV duty request Min.: 0%, Max.: 39.9% - - Pressure Discharge Valve Pressure discharge valve operation ON or OFF ON: Pressure discharge valve open This is the ECM command. -

-

VN Turbo System

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Target Booster Pressure Supported Target booster pressure support Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Target Booster Pressure Target booster pressure Target boosterpressure/

Min.: 0 kPa,

Max.: 320 kPa

Driving vehicle on level surface at 3000 rpm with full load: 190 to 210 kPa

-

Inspect while comparing with "MAP".

-

With the accelerator fully open, if the actual manifold absolute pressure (MAP) is low compared to the target booster pressure by at least 20 kPa for 5 second or more, a feeling of a lack of power will occur.

-

When the vehicle is driven with the engine speed at 3000 rpm or more and the accelerator pedal fully depressed, "MAP" is approximately equal to "Target Booster Pressure".

VN Turbo Command Supported VN turboco mmand supported Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Target VN Turbo Position Target VN turbo position Min.: 0%,

Max.: 100%

2 to 80%

-

When the nozzle vanes are fully closed (boost is applied), the value is 0%.

-

When the nozzle vanes are fully opened (boost is not applied), the value is 100%.

VN Turbo Command #2 Supported VN turbo command #2 supported Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Target VN Turbo Position #2 Target No. 2 VN turbo position Min.: 0%,

Max.: 100%

- - Actual VN Position Supported Actual VN position supported Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Actual VN Turbo Position Actual VN turbo position Min.: 0%,

Max.: 100%

2 to 80%

-

When the nozzle vane gets stuck or the movement is abnormal, the difference between this value and Target VN Turbo Position increases and the VN turbo motor output (duty) also increases.

-

Actual VN Turbo Position is controlled to match Target VN Turbo Position.

Actual VN Position #2 Supported Actual VN position #2 supported Unsupp or Supp -

-

Supp: The item is supported by the vehicle.

-

Unsupp: The monitor is not supported by the vehicle.

Actual VN Turbo Position #2 Actual No. 2 VN turbo position Min.: 0%,

Max.: 100%

- - VN Turbo Type VN turbo type Not Avl, Commo, Vacuum, CANcom, DC - Indicates the VN turbo vane actuation method.

-

DC motor system.

-

Negative-pressure diaphragm system.

-

Step motor system.

VN Turbo Max Angle VN turbo maximum opening amount Min.: 0%,

Max.: 100%

-

-

The maximum vane opening amount is displayed in %.

-

The VN turbo is operated between VN Turbo Max Angle and VN Turbo Min Angle when the Test the Turbo Charger Step Motor Active Test is performed.

VN Turbo Min Angle VN turbo minimum opening amount Min.: 0%,

Max.: 100%

-

-

The maximum vane opening amount is displayed in %.

-

The VN turbo is operated between VN Turbo Max Angle and VN Turbo Min Angle when the Test the Turbo Charger Step Motor Active Test is performed.

-

-

Various Vehicle Conditions 2 (All Data)

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Starter Signal Starter signal ON or OFF ON: Cranking Ignition switch (STA) output:

-

ON: Starter is operating

-

OFF: Starter is not operating

Cause of Out of Range:

-

OFF malfunction (ignition switch (STA) is ON but the signal is OFF and the starter is operating): Wire harness is open or shorted to ground

-

ON malfunction (ignition switch (STA) is off but the signal is ON and the starter is not operating): Wire harness is shorted to +B

-

Operation malfunction: ignition switch malfunction, starter relay malfunction, starter malfunction, battery or battery cable is defective, or wire harness is open or shorted

Symptoms when out of range:

-

Ignition switch is ON but the starter does not operate: Starting is not possible

-

Ignition switch is off but the starter continues to operate: STA signal malfunction (P0617) is stored

Neutral Position SW Signal Park/Neutral position switch status ON or OFF ON: Shift lever in neutral - Clutch Start SW Clutch start switch ON or OFF ON: Clutch pedal depressed When OFF with the clutch pedal depressed, the engine does not start. Stop Light Switch Stop light switch ON or OFF ON: Brake pedal depressed

OFF: Brake pedal released

Stop light switch (STP) operation condition:

-

ON: Light is on (Brake pedal is depressed)

-

OFF: Light is off (Brake pedal is released)

Cause of Out of Range:

-

OFF malfunction: Wire harness (stop light switch to ECM, stop light switch to +B) open or shorted to ground

-

ON malfunction: Wire harness (stop light switch to ECM) shorted to +B

-

Stop light switch

Symptoms when out of range:

Stop light switch malfunction DTC P0504 is stored

A/C Signal A/C (Air Conditioner) signal A/C (Air Conditioner) signal ON: A/C on Symptoms when out of range:

OFF malfunction (OFF even when

A/C switch is turned on):

-

Engine speed decreases temporarily when the A/C is operating.

Idle Up SW Idle up switch ON or OFF ON: Idle up - Immobiliser Communication Immobiliser communication ON or OFF ON: Normal

OFF: Engine cannot be started due to immobiliser communication malfunction

Cause of Out of Range:

-

Use of a non-registered key

-

Key battery is fully depleted

-

-

Check Mode (Check Mode)

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Check Mode Check mode ON or OFF ON: Check mode on Check Mode: The mode in which certain DTCs can be detected more easily and with higher sensitivity. SPD Test Result Check mode result for vehicle speed sensor Compl or Incompl - SPD Test Result: Check mode result for the vehicle speed sensor. -

Test Result (Monitor Status)

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Complete Parts Monitor Comprehensive component monitor Not Avl or Avail - * Fuel System Monitor Fuel system monitor Not Avl or Avail - * Misfire Monitor Misfire monitor Not Avl or Avail - * EGR/VVT Monitor EGR/VVT monitor Not Avl or Avail - * EGR/VVT Monitor EGR/VVT monitor Compl or Incmpl - * O2S(A/FS) Heater Monitor O2S(A/FS) heater monitor Not Avl or Avail - * O2S(A/FS) Heater Monitor O2S(A/FS) heater monitor Compl or Incmpl - * O2S(A/FS) Monitor O2S(A/FS) monitor Not Avl or Avail - * O2S(A/FS) Monitor O2S(A/FS) monitor Compl or Incmpl - * A/C Monitor A/C monitor Not Avl or Avail - * A/C Monitor A/C monitor Compl or Incmpl - * 2nd Air Monitor 2nd air monitor Not Avl or Avail - * 2nd Air Monitor 2nd air monitor Compl or Incmpl - * EVAP Monitor EVAP monitor Not Avl or Avail - * EVAP Monitor EVAP monitor Compl or Incmpl - * Heated Catalyst Monitor Heated catalyst monitor Not Avl or Avail - * Heated Catalyst Monitor Heated catalyst monitor Compl or Incmpl - * Catalyst Monitor Catalyst monitor Not Avl or Avail - * Catalyst Monitor Catalyst monitor Compl or Incmpl - * *:

Avail: The monitor is available on the vehicle.

Not Avl: The monitor is not available on the vehicle.

Incmpl / Compl: The item changes from Incmpl to Compl if the monitor was completed at least once at some time in the past. This item does not change when the ignition switch is turned off. However, the item changes back to Incmpl when DTCs are cleared or the battery cable is disconnected.

-

Various Vehicle Conditions 3 (All Data)

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note TC Terminal TC terminal status ON or OFF - - # Codes(Include History) Number of codes Min.: 0,

Max.: 255

0 Number of DTCs appearing at least once during the last 40 times the vehicle was warmed up. MIL MIL status ON or OFF OFF: MIL off - Time after DTC Cleared Time after DTC cleared Min.: 0 min.,

Max.: 65535 min.

Time after DTCs cleared Time elapsed since the DTCs were cleared (or shipment from the factory). Distance from DTC Cleared Distance driven after DTC cleared Min.: 0 km,

Max.: 65535 km

Distance driven after DTCs cleared

-

Distance driven since the DTCs were cleared.

-

(Data List "Distance from DTC clear") - (Freeze frame data "Distance from DTC cleared") = Distance driven since the abnormality occurred.

Warmup Cycle Cleared DTC Warmup cycles after DTC cleared Min.: 0,

Max.: 255

-

-

Number of engine warmup since DTCs were cleared.

-

(Data List "Warmup Cycle Cleared DTC") - (Freeze frame data "Warmup Cycle Cleared DTC") = Warmup cycles since the abnormality occurred.

Dist Batt Cable Disconnect Distance driven after battery cable disconnected Min.: 0 km,

Max.:16777215 km

- - OBD Requirements OBD requirement - - EOBD (Euro OBD) Number of Emission DTC Emissions-related DTCs - - - TC and TE1 TC and CG (TE1) terminals of DLC3 ON or OFF - When the "Connect the TC and TE1" Active Test is performed, the system behaves as if TC and CG were connected. Total Distance Traveled Total distance 3traveled Min.: 0 km (0 mile),

Max.: 16777215 km (10425361 mile)

Total distance vehicle driven after battery cable disconnected - -

-

Diesel Starting

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Engine Speed (Starter Off) Engine speed when starter off Min.: 0 rpm,

Max.: 1594 rpm

- Engine speed immediately after starting the engine. Starter Count Starter on count Min.: 0,

Max.: 255

- Number of times the starter turned on from the time the ignition switch was turned to ON. Run Dist of Previous Trip Distance driven during previous trip Min.: 0 km,

Max.: 261 km

- Before 5 seconds elapse after starting the engine, which is the DTC P1604 (Startability Malfunction) detection duration, this parameter indicates the distance driven during the previous trip. After 5 seconds elapse after starting the engine, this parameter indicates the distance driven during the current trip calculated from the vehicle speed signal.

Tech Tips

-

Run Dist of Previous Trip in the freeze frame data present when the startability malfunction occurred (DTC P1604 detected) indicates the distance driven during the previous trip, but in all other cases, such as for the snapshot data of the Data List (real-time measurements), or for freeze frame data present when DTCs other than P1604 were detected, the value indicates the distance driven during the current trip.

-

If DTCs indicating insufficient power or problems with the DPF system, diesel throttle are stored, confirm this item in the freeze frame data of the stored DTCs to determine the distance driven when the DTCs were stored.

The distance driven can be used as a reference when troubleshooting.

-

-

Various Vehicle Conditions 4 (All Data)

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Electric Duty Feedback Value Electric load feedback value Min.: 0 mm3/st,

Max.: 39.8 mm3/st

0 to 7 mm3/st

Expected injection volume increase after the electrical load turns from off to on. A/C Duty Feedback Value A/C load feedback value Min.: 0 mm3/st,

Max.: 39.8 mm3/st

0 to 3.7 mm3/st

Expected injection volume increase after the A/C turns from off to on. PS Duty Feedback Value Power steering load feedback value Min.: 0 mm3/st,

Max.: 39.8 mm3/st

3.2 mm3/st

Expected injection volume increase after the power steering turns from off to on. Idle Injection Volume (Min) Idle minimum injection volume Min.: 0 mm3/st,

Max.: 39.8 mm3/st

- - Engine Starting Time Engine starting time Min.: 0 ms,

Max.: 267000 ms

-

-

This is the time elapsed after the starter turns on until the engine speed reaches 400 rpm.

-

This value is cleared 5 seconds after the engine is started and the value is displayed as 0 ms.

Minimum Engine Speed Minimum engine speed Min.: 0 rpm,

Max.: 51199 rpm

- - ACT VSV A/C cut status for Active Test ON or OFF - "Control the A/C Cut Signal" Active Test support data. Brake Override System Brake override system status ON or OFF ON: Brake override system operating - -

-

Vehicle Information

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Model Code Model code - - Used for identifying the model code:

KUN##

Engine Type Engine type - - Used for identifying the engine type:

1KD-FTV

Cylinder Number Number of cylinders Min.: 0,

Max.: 255

- Used for identifying the number of cylinders:

4

Transmission Type Transmission type - - Used for identifying transmission type:

-

MT: Manual transmission

-

ECT: Automatictransmission

Destination Destination - - Identifying destination Model Year Model year Min.: 1900,

Max.: 2155

- Used for identifying the model year:

20##

System Identification System identification - - Used for identifying the engine system -

-

Compression

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Engine Speed of Cyl #1 Engine speed for No. 1 cylinder Min.: 0 rpm,

Max.: 51199 rpm

Engine speeds of all cylinders almost same

-

Output only when the "Check the Cylinder Compression" Active Test is performed.

-

Indicates the speed of each cylinder when cranking.

Example - Normal: Engine speeds of all cylinders are approximately equal.

When No. 1 cylinder compression is low, "Engine Speed of Cyl #1" is approximately 300 rpm, and "Engine Speed of Cyl #2 to #4" is approximately 200 rpm.

Symptoms when out of range:

When the engine speeds of all cylinders are not equal, idling will be rough.

Engine Speed of Cyl #2 Engine speed for No. 2 cylinder Min.: 0 rpm,

Max.: 51199 rpm

Engine speeds of all cylinders almost same Same as Engine Speed of Cyl #1 Engine Speed of Cyl #3 Engine speed for No. 3 cylinder Min.: 0 rpm,

Max.: 51199 rpm

Engine speeds of all cylinders almost same Same as Engine Speed of Cyl #1 Engine Speed of Cyl #4 Engine speed for No. 4 cylinder Min.: 0 rpm,

Max.: 51199 rpm

Engine speeds of all cylinders almost same Same as Engine Speed of Cyl #1 Av Engine Speed of All Cyl Average engine speed for all cylinders Min.: 0 rpm,

Max.: 51199 rpm

-

-

Output only when the Active Test "Check the Cylinder Compression" is performed.

-

Indicates the average engine speed of all cylinders during cranking.

-

-

Automatic Transmission (All Data)

Powertrain > Engine > Data ListTester Display Measurement Item Range Normal Condition Diagnostic Note Shift SW Status (N,P Range) Supported Status of park/neutral position switch (N or P) supported Supp or Unsupp - - Shift SW Status (N,P Range) Park/neutral position switch status ON or OFF

-

ON: Shift lever in P or N

-

OFF: Shift lever not in P or N

- Shift SW Status (D Range) Park/neutral position switch status ON or OFF

-

ON: Shift lever in D, S, "+" or "-"

-

OFF: Shift lever not in D, S, "+" or "-"

When the shift lever position displayed on the GTS differs from the actual position, adjustment of the park/neutral position switch or the shift cable may be incorrect.

Tech Tips

When the failure still occurs even after adjusting these parts, refer to DTC P0705.

-

-

ACTIVE TEST

Tech Tips

Using the GTS to perform Active Tests allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

-

Enter the following menus: Powertrain / Engine / Active Test.

-

Perform the Active Test.

Powertrain > Engine > Active TestTester Display Measurement Item Control Range Diagnostic Note Activate the VSV for Swirl Control Valve Activate the VSV for swirl control valve ON/OFF - Control the A/C Cut Signal Confirm that the vehicle is stopped and the engine is idling ON/OFF Confirm that the vehicle is stopped and the engine is idling Connect the TC and TE1 Turn on the TC and TE1 connection ON/OFF - Test the Fuel Leak Pressurize the common rail interior and check for fuel leaks Stop/Start

-

Fuel pressure inside common rail pressurized to specified value and engine speed increased to 2000 rpm when ON is selected

-

Above conditions preserved while test is ON

Tech Tips

If this Active Test is performed when the engine is cold, combustion may become unstable. However, this is not a malfunction. It is only necessary to confirm that the pressure rises to the target pressure and that there are no fuel leaks.

Test the Turbo Charger Step Motor Activate the turbocharger sub-assembly 0 to 60% Test is possible when the following conditions are met:

-

Ignition switch ON.

-

Engine is stopped.

Activate the VN Turbo Open Activate the turbocharger sub-assembly ON/OFF Confirm that the engine is running. Control the Select Cylinder Fuel Cut Selected cylinder (cylinder #1 to #4) injector fuel cut ON/OFF

-

Confirm that the vehicle is stopped and the engine is idling.

-

If the running condition of the engine does not worsen even though injection of the designated cylinder is stopped, the cylinder can be determined to be malfunctioning.

Check the Cylinder Compression Check the cylinder compression pressure* ON/OFF Fuel injection is stopped while the test is ON. Tech Tips

*: When cranking the engine, the Active Test measures the speed of each cylinder. In this Active Test, the fuel of all cylinders is cut when the engine is cranked for approximately 10 seconds.

At this time, the speed of each cylinder is measured. If the speed of one cylinder is more than the other cylinders, it can be determined that the compression pressure of that cylinder is lower than the other cylinders.

-

Warm up the engine.

-

Turn the ignition switch off.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON and turn the GTS on.

-

Enter the following menus: Powertrain / Engine / Active Test / Check the Cylinder Compression.

Tech Tips

If the results are not displayed normally, select the display items from the Data List before performing the Active Test. Enter the following menus: Powertrain / Engine / Data List / Compression / Engine Speed of Cyl #1, Engine Speed of Cyl #2, Engine Speed of Cyl #3, Engine Speed of Cyl #4 and Av Engine Speed of All Cyl.

-

While the engine is not running, press the RIGHT or LEFT button to change Check the Cylinder Compression to ON.

Tech Tips

After performing the above procedure, the "Check the Cylinder Compression" Active Test will start. Fuel injection for all cylinders is prohibited and the engine speed measurement of each cylinder enters standby mode.

-

Crank the engine for about 10 seconds.

-

Monitor the engine speed (Engine Speed of Cyl #1 to #4, Av Engine Speed of All Cyl) displayed on the GTS.

Tech Tips

At first, the GTS display will show the engine speed measurement of each cylinder to be extremely high. After approximately 10 seconds of engine cranking, the engine speed measurement of each cylinder will change to the actual engine speed.

Note

-

After the "Check the Cylinder Compression" Active Test is turned on, it will automatically turn off after 255 seconds.

-

When the "Check the Cylinder Compression" test is off and the engine is cranked, the engine will start.

-

If the "Check the Cylinder Compression" test needs to be performed after it is turned on and performed once, press "EXIT" to return to the Active Test menu screen. Then perform the "Check the Cylinder Compression" test again.

-

Use a fully-charged battery.

-

-

-

SYSTEM CHECK

-

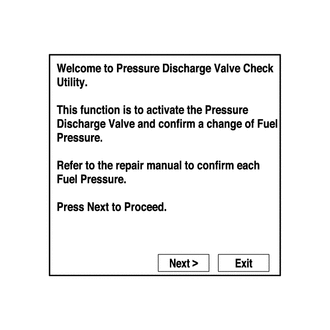

Activate the Pressure Discharge Valve Check

Tech Tips

-

This is the procedure for troubleshooting fuel pressure control malfunctions and combustion problems.

-

Malfunctions can be determined by checking the fuel pressure when performing a fuel cut and operating the pressure discharge valve with the GTS.

-

During "Pressure Discharge Valve Check", the GTS measures the fuel pressure while the engine is running, after the engine is stopped, and after the pressure discharge valve operates.

-

Connect the GTS to the DLC3.

-

Turn the ignition switch to ON.

-

Turn the GTS on.

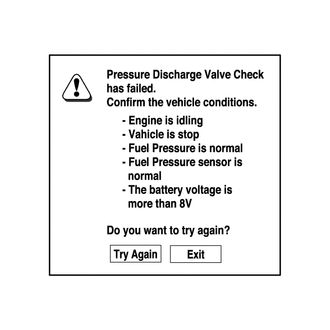

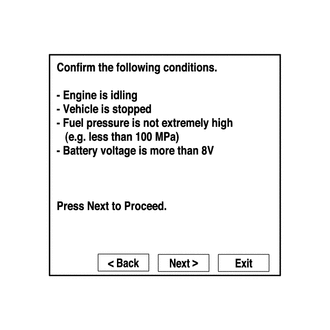

Note

Confirm the following conditions:

-

Engine is idling.

-

Vehicle is stopped.

-

Fuel pressure is not extremely high (below 100000 kPa).

-

Fuel pressure is not extremely low (higher than 26000 kPa).

-

Fuel pressure sensor is normal.

-

Battery voltage is higher than 8 V.

Tech Tips

When the common rail pressure is unstable, the fuel pressure may decrease to a level where the test cannot be performed. In this situation, wait until the common rail pressure meets the test condition, and then perform the test.

-

-

Enter the following menus: Powertrain / Engine / Utility / Pressure Discharge Valve Check.

Powertrain > Engine > UtilityTester Display Pressure Discharge Valve Check -

Press "Next".

-

Press "Next" again to proceed.

-

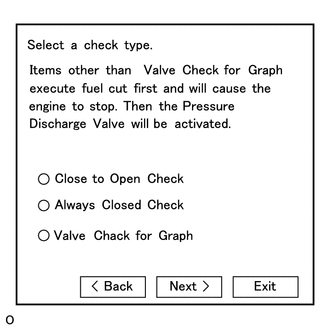

Select the "Pressure Discharge Valve Check" type.

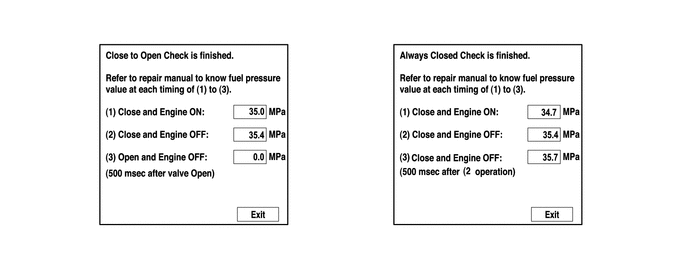

Tech Tips

-

"Close to Open Check" opens the pressure discharge valve after the engine stops.

-

"Always Closed Check" holds the pressure discharge valve closed during the check.

-

-

Press "Next".

-

Perform troubleshooting based on the measurement results.

Tech Tips

-

During "Close to Open Check", if there is no large change in fuel pressure when the pressure discharge valve is closed while the engine is running and after the engine is stopped, and if the value is 0 kPa when the pressure discharge valve is open, the system is normal.

-

Perform "Always Closed Check" if the value is not 0 kPa when the pressure discharge valve is open during "Close to Open Check". If the results are the same as during "Close to Open Check", there is a pressure discharge valve operation malfunction.

-

If the fuel temperature is high, perform "Pressure Discharge Valve Check" after the fuel has cooled to the outside air temperature.

-

If a large amount of fuel is leaking, the fuel pressure decreases when the engine is stopped. However, the condition of the pressure discharge valve can still be determined by comparing the measurement results of "Close to Open Check" and "Always Closed Check".

-

-

-