СИСТЕМА СНИЖЕНИЯ ТОКСИЧНОСТИ ОТРАБОТАВШИХ ГАЗОВ ПРОВЕРКА БЕЗ СНЯТИЯ С АВТОМОБИЛЯ

CAUTION / NOTICE / HINT

CAUTION:

To prevent injury due to contact with an operating fan and generator V belt or cooling fan, keep your hands and clothing away from the fan and generator V belt and cooling fans when working in the engine compartment with the engine running.

PROCEDURE

-

CHECK FUEL CUT RPM

CAUTION:

To prevent injury due to contact with an operating fan and generator V belt or cooling fan, keep your hands and clothing away from the fan and generator V belt and cooling fans when working in the engine compartment with the engine running.

-

Start and warm up the engine.

-

Maintain the engine speed at 3000 rpm.

-

Use a sound scope to check for injector operating sounds.

-

Check that when the accelerator pedal is released, fuel injector operation noise stops momentarily and then resumes.

If the result is not as specified, check the fuel injector assembly, wire harness and ECM.

-

-

VISUALLY INSPECT HOSES, CONNECTORS AND GASKETS

-

Visually check that the hoses, connections and gaskets have no cracks, leaks or damage.

Note

-

Detachment or other problems with the engine oil level dipstick, oil filler cap sub-assembly, PCV hose and other components may cause the engine to run improperly.

-

Air suction caused by disconnections, looseness or cracks in the parts of the air induction system between the throttle body with motor assembly and cylinder head will cause engine failure or engine malfunctions.

If the result is not as specified, replace parts as necessary.

-

-

-

CHECK FUEL TANK ASSEMBLY

-

Visually check for deformation, cracks or fuel leakage.

-

-

CHECK PURGE VSV

CAUTION:

To prevent injury due to contact with an operating fan and generator V belt or cooling fan, keep your hands and clothing away from the fan and generator V belt and cooling fans when working in the engine compartment with the engine running.

-

Check that the vacuum hose is connected correctly.

-

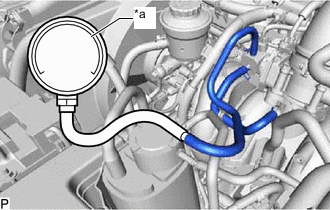

*a Vacuum Gauge Disconnect the vacuum hose from the canister and connect a vacuum gauge.

-

Using the procedure below, perform a purge VSV operation inspection when the engine coolant temperature is 74 °C (165 °F) or higher (while the engine is hot (purge VSV is opened)).

Tech Tips

The ECM turns the purge VSV on so that a vacuum is created in the intake manifold and the canister's fuel vapors are purged to the intake manifold.

-

Purge VSV operation inspection procedure.

-

When the engine is idling, the vacuum gauge indicates 40 kPa (300 mmHg, 11.8 in.Hg) or higher.

Result Result Procedure Yes Purge VSV operation normal No Go to next step -

Inspect the purge VSV.

Result Result Procedure OK Check wire harness and ECM NG Replace purge VSV

-

-

-